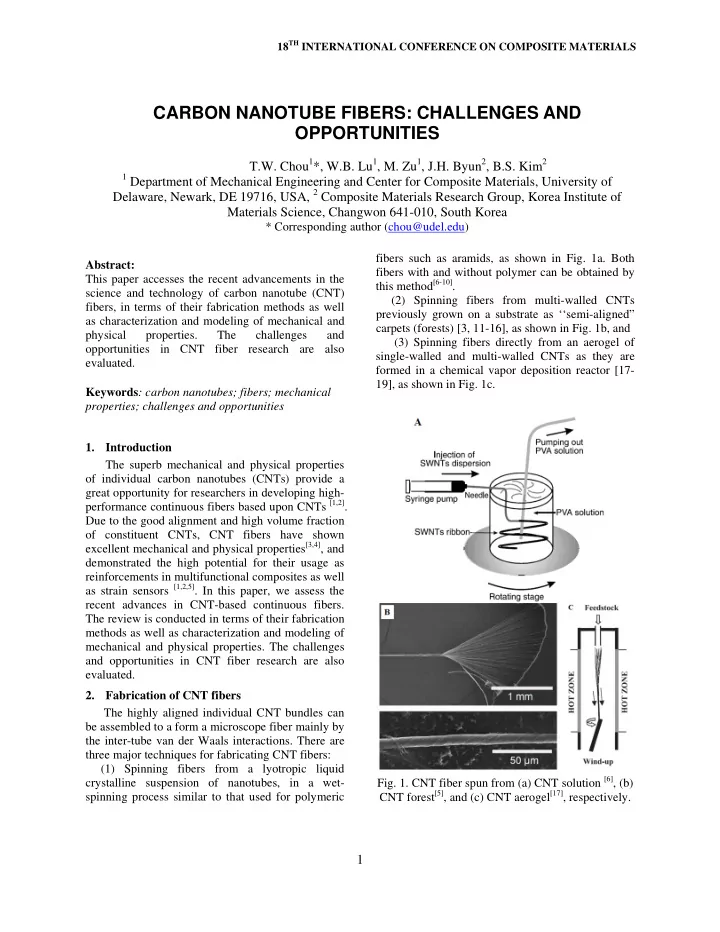

18 TH INTERNATIONAL CONFERENCE ON COMPOSITE MATERIALS CARBON NANOTUBE FIBERS: CHALLENGES AND OPPORTUNITIES T.W. Chou 1 *, W.B. Lu 1 , M. Zu 1 , J.H. Byun 2 , B.S. Kim 2 1 Department of Mechanical Engineering and Center for Composite Materials, University of Delaware, Newark, DE 19716, USA, 2 Composite Materials Research Group, Korea Institute of Materials Science, Changwon 641-010, South Korea * Corresponding author (chou@udel.edu) fibers such as aramids, as shown in Fig. 1a. Both Abstract: fibers with and without polymer can be obtained by This paper accesses the recent advancements in the this method [6-10] . science and technology of carbon nanotube (CNT) (2) Spinning fibers from multi-walled CNTs fibers, in terms of their fabrication methods as well previously grown on a substrate as ‘‘semi-aligned” as characterization and modeling of mechanical and carpets (forests) [3, 11-16], as shown in Fig. 1b, and physical properties. The challenges and (3) Spinning fibers directly from an aerogel of opportunities in CNT fiber research are also single-walled and multi-walled CNTs as they are evaluated. formed in a chemical vapor deposition reactor [17- 19], as shown in Fig. 1c. Keywords : carbon nanotubes; fibers; mechanical properties; challenges and opportunities 1. Introduction The superb mechanical and physical properties of individual carbon nanotubes (CNTs) provide a great opportunity for researchers in developing high- performance continuous fibers based upon CNTs [1,2] . Due to the good alignment and high volume fraction of constituent CNTs, CNT fibers have shown excellent mechanical and physical properties [3,4] , and demonstrated the high potential for their usage as reinforcements in multifunctional composites as well as strain sensors [1,2,5] . In this paper, we assess the recent advances in CNT-based continuous fibers. The review is conducted in terms of their fabrication methods as well as characterization and modeling of mechanical and physical properties. The challenges and opportunities in CNT fiber research are also evaluated. 2. Fabrication of CNT fibers The highly aligned individual CNT bundles can be assembled to a form a microscope fiber mainly by the inter-tube van der Waals interactions. There are three major techniques for fabricating CNT fibers: (1) Spinning fibers from a lyotropic liquid Fig. 1. CNT fiber spun from (a) CNT solution [6] , (b) crystalline suspension of nanotubes, in a wet- CNT forest [5] , and (c) CNT aerogel [17] , respectively. spinning process similar to that used for polymeric 1

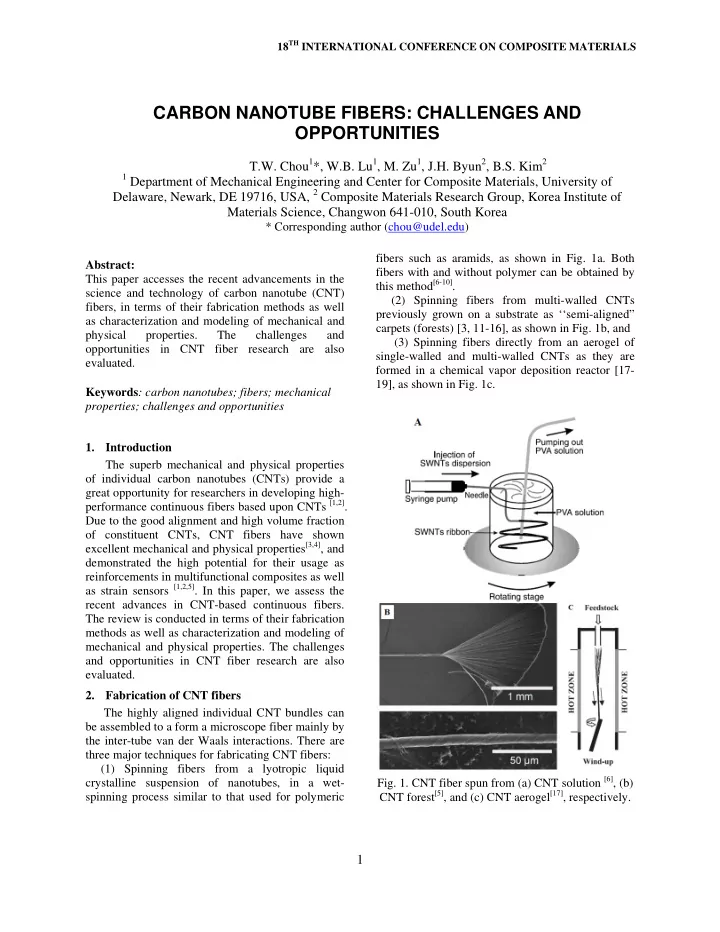

3. Characterization of CNT fiber properties (a) In the past decade, intensive experimental studies have been conducted by researchers to characterize the performance of CNT fibers. Fig. 2(a) summarizes the tensile strength and modulus of CNT fibers fabricated from the aforementioned methods. It is found that fibers spun from CNT aerogel possess the highest tensile strength so far. CNT length has significant effect on fiber tensile properties. For example, Zhang et al. [15] spun CNT fibers with comparable diameters (about 4 m) from arrays of 300, 500, and 650 mm in length and compared their strength. As shown in Fig. 2(a), the tensile strength increases with increasing CNT length, from 0.32 to 0.56 and to 0.85 GPa, (b) respectively. It is suggested that longer nanotube could not only lead to a higher friction force at the nanotube interfaces, but also reduce the fraction of CNT ends, which are regarded as defects in the fiber. Koziol et al. [19] pointed out that CNTs of larger diameter with fewer walls would collapse during fiber fabrication, which could increase the contact area between CNTs and enhance the load transfer efficiency. The effects of the post-processes, such as liquid (c) shrinking and spinning, on the mechanical properties of CNT fibers have also been studied [14-16] . These post-processes could densify the as-spun fibers and enhance the load transfer efficiency between CNTs. Fig. 2c and d are two examples showing the effects of liquid shrinking [14] and spinning [15] . [20] reported several Recently, Deng et al. fundament studies relevant to the mechanical behavior of CNT fibers spun from CNT forest. In- situ SEM observations have shown that under tensile loading, several distinct deformation stages can be (d) identified, namely initial tightening of the CNT bundle, followed by loosening, tightening again and final fracture at ultimate load. Figure 3a shows a typical fiber tensile stress-strain curve. The elastic moduli identified on the curve correspond approximately to the first and second tightening stages. Figure 3b shows the data of measured tensile strength at various fiber diameters. The fiber strength decreases with increasing fiber diameter. In order to analyze the statistic characteristic of CNT Fig. 2 (a) Comparison of tensile stiffness and fiber strength, a modified Weibull strength theory strength of CNT fibers fabricated by different was applied to the test data. It is concluded that the methods [3,8,15,19] ; and the effects of (b) CNT length [15] , (c) liquid shrinking [14] as well as (d) spinning [15] . 2

strength of CNT fibers shows smaller scattering than CNT entanglements have been observed in CNT fibers and films. Lu and Chou [23] studied the those of multi-walled CNTs but larger scattering than those of commercial carbon and glass fibers. mechanical behaviors of the entanglements using The interfacial behaviors of CNT fiber in an epoxy both theoretical analysis and atomistic simulation matrix have also been investigated through single methods. The CNT entanglement is modeled as two fiber fragmentation test [20] and microdroplet test [21] . connecting self-folded CNTs (SFCNTs), as shown in Figure 4. The critical length for the formation of the (a) SFCNT is around 12.00��� � ⁄ , where �� and � are the CNT bending stiffness and interfacial binding energy, respectively. The mechanical responses of the CNT entanglement under tensile force, as well as the effects of CNT radius and length, have also been studied. (b) Fig. 4 Theoretical model for analyzing the mechanical response of CNT entanglement in fibers [23] Fig. 3. (a) A typical tensile stress-strain curve of Contrary to the high stiffness along the axial CNT fibers; (b) CNT fiber strength at various fiber diameters [20] direction, CNTs are relatively compliant in the radial direction. CNTs are susceptible to deformation or 4. Analysis and Modeling even collapse under the inward force induced by The characterization of CNT fibers as well as fiber twisting [19, 25, 26] . Lu et al . [24] studied the cross- their constituent CNTs has motivated some sectional transformation of SWCNTs during radial analytical work for modeling their properties. deformation using both atomistic simulation and Existing research work has focused on, for example, continuum theoretical analysis. There exist two the statistical fiber strength [22] , as well as the critical radii R 1 and R 2 , which are 1.05nm and entanglement [23] and radial deformation [24] of CNTs 1.90nm, respectively. For SWCNTs with radius less in the fiber. than R 1 , the initial circular states are found to be Beyerlein et al. [22] investigated the effects of yarn most stable; for SWCNTs with the radius between diameter and gauge length on the statistical strength R 1 and R 2 , the collapsed states are metastable, but of CNT fibers spun from CNT forest. A Monte the circular states are energetically favorable; and Carlo simulation model has been developed to for SWCNTs with radius large than R 2 , the fully predict the relationship between fiber nanostructure collapsed state becomes energetically favorable. The and tensile strength. Predictions indicate that the energy variation during the radial deformation has mean and statistical variation in strength decrease as also been investigated. Both energy barrier and the surface twist angle, number of CNTs in the cross energy difference for the collapse of SWCNTs section and gauge length of the yarn increase. decrease with increasing SWCNT radius. 3

Recommend

More recommend