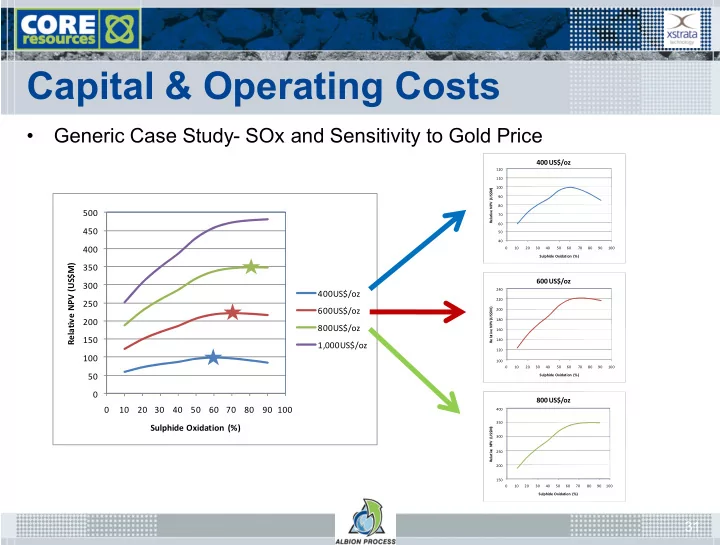

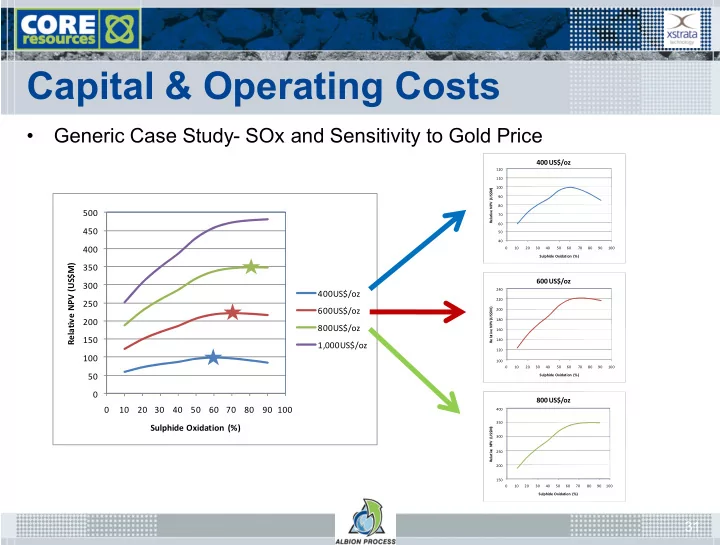

Capital & Operating Costs • Generic Case Study- SOx and Sensitivity to Gold Price 400US$/oz 120 110 100 Relative NPV (US$M) 90 80 500 70 60 450 50 40 400 0 10 20 30 40 50 60 70 80 90 100 Sulphide Oxidation (%) Relative NPV (US$M) 350 600US$/oz 300 240 400US$/oz 220 250 600US$/oz tive NPV (US$M) 200 200 180 800US$/oz 160 Re la 150 140 1,000US$/oz 120 100 100 0 10 20 30 40 50 60 70 80 90 100 50 Sulphide Oxidation (%) 0 800US$/oz 0 10 20 30 40 50 60 70 80 90 100 400 350 Sulphide Oxidation (%) PV (US$M) 300 e N Relativ 250 200 150 0 10 20 30 40 50 60 70 80 90 100 Sulphide Oxidation (%) 31

Project Updates 32

Project Updates • Las Lagunas Project Developed by EnviroGold Limited Location: Dominican Republic JORC Resource 5.14Mt tailings @ 3.76 g/t Au & 38.62 g/t Ag Flotation + Albion Process + CIL flowsheet Lycopodium Minerals QLD P/L (Brisbane) completed detailed engineering Design basis: 800ktpa tailings and 80k oz/y Ag+Au Project Life- 6.5 years Construction by local contractor (IRISA) >40% complete Albion Process leach tanks (SS) to be shipped from Taiwan in early May 2010 Commissioning delayed until early 2011 due to financing issues 33

Project Updates • Certej Project Developed by European Goldfields Limited Location: Romania Resource ~46.9Mt ore @ ~1.6 g/t Au & ~11.5 g/t Ag Flotation + Albion Process + CIL flowsheet Aker Solutions (UK) completed basic engineering Design basis: 3Mtpa ore and 160k oz/y Au + 800k oz/y Ag Project Life- 16 years All permits now in place along with financing Commissioning expected to start late 2011 / early 2012 34

Project Updates • Other Projects/Applications Joanna Project- Mines Aurizons Arsenopyrite refractory gold application (110k oz/y Au) o Pilot work commencing ( hrl testing) o Numerous testwork programs supporting process studies Enargite Cu/Ag/Ag (projects in South America, SE Asia…) o Pyrite gold (projects in QLD, Armenia, Mexico, Kazakhstan…) o Arsenopyrite gold (projects in WA, New Zealand…) o Internally with Xstrata PLC projects in advanced state of testing and engineering through to commercial application Copper/Cobalt applications – dust leaching plant o Nickel application o Zinc applications – smelter expansions o 35

Project Development Program 36

Project Development Program • Steps involved 1. Define and collect preliminary key projects and metallurgical data about the likely feed and range of feed material to be treated via the Albion Process 2. Undertake a high level economic assessment of the process (indicative order of magnitude costing exercise) 3. Phase 1 testing- Initiate an orientation testwork program to broadly demonstrate the technical feasibility of the process and generate key process design parameters to enable a preliminary process feasibility study to be completed 4. Commence a preliminary process study to establish the capital and operating costs for the process specific for project and target feed material 5. Phase 2 testing- Optimize process conditions and undertake testwork on variability samples 6. Phase 3 testing- Continuous pilot trial work 7. Commence bankable feasibility study (BFS) design and costing work leading into basic and detailed engineering and finally plant construction and commissioning 37

Project Development Program • Steps involved- cost and duration Step No. Dscription Cost Duration Sample Responsible 1 Data collection 2-4 weeks Client/Core - 2 Highlevel OOM Capex/Opex - 2-4 weeks Core 3 Phase 1- testing ~A$30-40K 6-8 weeks 10-20 kg hrl testing 4 Process Study ~A$20K 4-6 weeks XT/Core 5 Phase 2- testing ~A$50-100K 8-12 weeks 20-50 kg hrl testing 6 Phase 3- testing ~A$500-750K 3-6 months >250 kg hrl testing/vendors 7 Feasibility study etc… ? ? Engineering Houses* * Suggested EPCM contractors with Albion Process experience: Lycopodium (Las Lagunas) and Aker Solutions (Certej) 38

Project Development Program • Testwork- hrl testing (www.hrltesting.com) 39

THANK YOU • Any questions? Duncan Turner PhD Mike Hourn Core Resources Pty Ltd Xstrata Technology General Manager Albion Process Manager Hydrometallurgy dturner@coreresources.com.au mhourn@xstratatech.com.au +61 7 3637 8105 +61 7 3833 8539 40

Recommend

More recommend