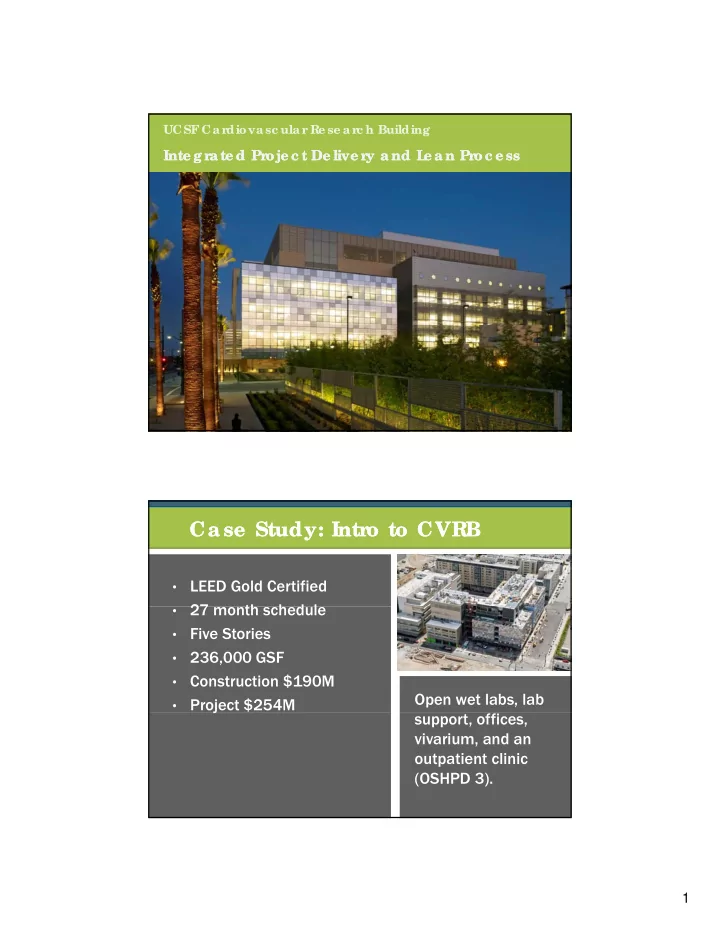

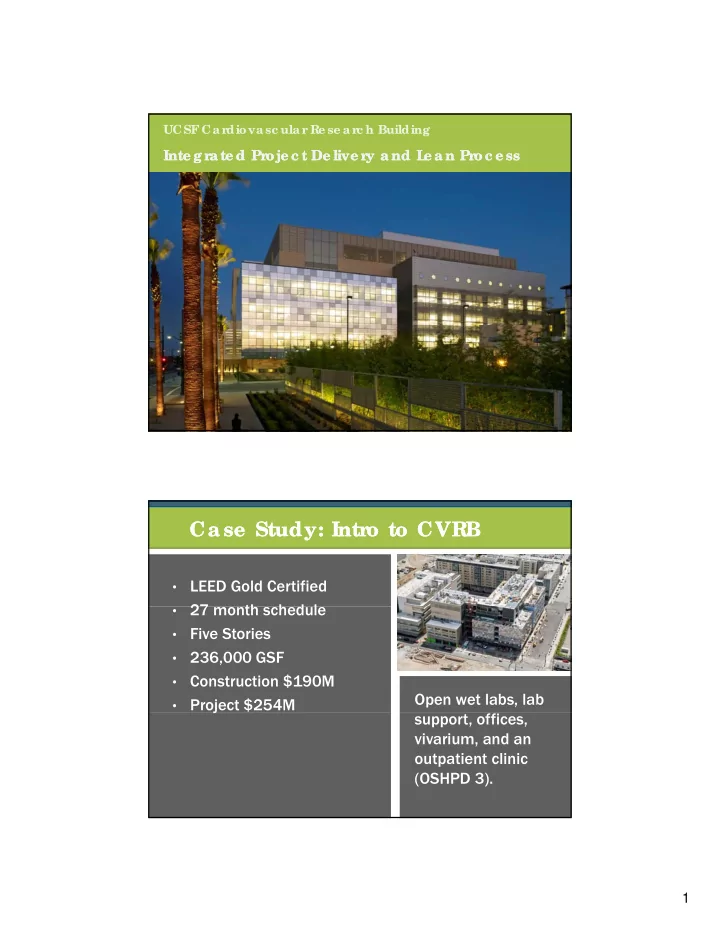

UCSF Ca rdiova sc ula r Re se a rc h Building Inte g ra te d Proje c t De live ry a nd L Inte g ra te d Proje c t De live ry a nd L e a n Proc e ss e a n Proc e ss Ca se Study: Intro to CVRB Ca se Study: Intro to CVRB • LEED Gold Certified • 27 month schedule 27 th h d l • Five Stories • 236,000 GSF • Construction $190M Open wet labs, lab • Project $254M j support, offices, vivarium, and an outpatient clinic (OSHPD 3). 1

IPD E IPD E volution volution Owner Architect Contractor T T e a m Org a niza tion e a m Org a niza tion Owner UCSF UCSF Cambridge CM Structural Eng. Architect Rutherford SmithGroup & Chekene Jim Jennings Lab Planners GPR All Other Design Consultants 2

T T e a m Org a niza tion e a m Org a niza tion Owner UCSF UCSF All Other Cambridge Trades CM (lump sum bid) Structural Eng. Contractor Architect Rutherford Rudolph and SmithGroup & Chekene Sletten Jim Jennings Exterior Skin Walters & Wolf Lab Planners GPR Electrical All Other Rosendin Design Mechanical/ Consultants Plumbing Southland T T e a m Se le c tion e a m Se le c tion Owner UCSF B Best Value t V l Prequalification f Selection Selection General All Other Contractor Trades Design Build Mechanical/ Electrical Plumbing Exterior Skin 3

Choosing the T Choosing the T e a m e a m Personalities of Select Team Members Individuals on Based on Experience Based on Experience Team Matter � Building Information Modeling (BIM) � Integrated Project Delivery � Design-Build for Key Trades � Lean Construction L C t ti Techniques Pre qua lific a tion T Pre qua lific a tion T e a m Se le c tion e a m Se le c tion • Prequalification prior to low Fast Track Buyout – bid process bid process E Early Packages l P k • Prequalification Based on: Management Experience with • Similar Projects • Management of DB Subs • Lean Construction • Integrated Team 4

Be st Va lue Se le c tion Be st Va lue Se le c tion • Evaluate Contractors for: • Categories: • Categories: Management Capability • Safety • Financial Strength • Labor Compliance • Relevant Experience • Divide Points into Bid to Determine Lowest Cost Per Point • Evaluations are by Points Earned in Each Category De sig n Pre se nta tion De sig n Pre se nta tion 5

De sig n Pre se nta tion De sig n Pre se nta tion Conceptual Massing and Orientation De sig n Pre se nta tion De sig n Pre se nta tion 6

De sig n F De sig n F e a ture s e a ture s Architectural Features Glass at Offices Metal Panel and Mesh at Labs Terracotta at Support Spaces De sig n Pre se nta tion De sig n Pre se nta tion Planning Concepts – Scientific Collaboration and Translational Research 7

De sig n Pre se nta tion De sig n Pre se nta tion Planning Concepts – Scientific Collaboration and Translational Research De sig n Pre se nta tion De sig n Pre se nta tion Planning Concept - Efficiency and Flexibility No Rated Corridors Lab Floor Efficiency Ratio 0.76 8

Ma ximizing E Ma ximizing E ne rg y E ne rg y E ffic ie nc y ffic ie nc y Conceptual Segregation of Occupancies Horizontal Horizontal Vertical Vertical Ma ximizing E Ma ximizing E ne rg y E ne rg y E ffic ie nc y ffic ie nc y Conceptual Systems Integration with Planning 9

Ma ximizing E Ma ximizing E ne rg y E ne rg y E ffic ie nc y ffic ie nc y Architectural Features Operable Windows at Offices Window Shading at Labs Minimal Openings at Vivarium Ma ximizing E Ma ximizing E ne rg y E ne rg y E ffic ie nc y ffic ie nc y Mechanical Design � Variable Speed Fans � Low Velocity Air Systems � Water Saving Plumbing Fixtures � Building Systems Control Electrical Design � Lighting Control Throughout g t g Co t o oug out � Energy Efficient Lighting 10

F F our Ke y Conc e pts our Ke y Conc e pts 1. Integrating Technology 2. Communication 3. Dispute Resolution 4. Incentives 1. Inte g ra ting T 1. Inte g ra ting T e c hnolog y e c hnolog y • Whole Team in BIM • BIM Coordination = More BIM C di ti M Exchange of Ideas, Increased Commitment • Facilities Group on BIM • Define Team Member BIM is a tool R l Roles in Coordination i C di ti which makes IPD • Foster Trust to Enable possible Good Performance & Collaborative Approach 11

2. Communic a tion 2. Communic a tion Creating the tone • Goal Setting • Big Room • Schedules Pull Sessions Last Planner Last Planner Goa l Se tting Goa l Se tting 12

Big Room Big Room – – Cre a ting the T Cre a ting the T one one CAMBRIDGE SMITHGROUP SOUTHLAND UCSF • All Key Members in ROSENDIN one trailer one trailer IOR • Team Approach COMMON Encouraged by owner PROJECT VISION • Blurring the lines W& W RUDOLPH & SLETTEN working as a team Sc he dule Proc e ss Sc he dule Proc e ss Weekly assignments, reliable promises, Remove measure PPC, and learn constraints, make work ready k d Specify handoffs, Weekly collaborative Schedule Work Plan Lookahead planning Detail Planning Set milestones, Phase/Pull establish project Scheduling duration Master Schedule Design Construction 13

Sc he dule Proc e ss Sc he dule Proc e ss Pull Schedule L Last Planner Pl Inte g ra ting T Inte g ra ting T e c hnolog y e c hnolog y – – 4D 4D 14

3. Dispute Re solution 3. Dispute Re solution • Clear, Fair, Process Everyone Can Agree to Everyone Can Agree to • Set Clear Time Frames • Emphasize a Collaborative Approach • Review Key Project y j Process & Modify if Necessary 4. Inc e ntive 4. Inc e ntive – – Construc tion Construc tion Percent Planned • Performance Based Complete & Incentives Incentives S h d l Mil Schedule Milestone • Sharing Risk and Based Incentive Reward Program • Set Up a Way to Share the Reward • Everyone Fails Together Everyone Fails Together or Succeeds Together 15

Inc e ntive Inc e ntive – – Construc tion Construc tion Percent Planned Planned P Planned Percent rcent Comple Complete Complete & (PPC) (PPC) (PPC) (PPC) S h d l Mil Schedule Milestone • Number of tasks Based Incentive completed vs number of Program tasks planned • 10 tasks planned for this week • 8 tasks completed this week • PPC = 80% Inc e ntive Inc e ntive – – Construc tion Construc tion Percent Planned SCHEDULE INCENTIVE SCHEDULE INCENTIVE Complete & MILES MILESTONES: Schedule Milestone S h d l Mil • Sept. 26, 2008: Based Incentive Structural Steel Mobilization Program • Jan. 27, 2009: Steel & Decking Complete • March 11, 2009: SOG & Deck Pours SOG & Deck Pours • May 27, 2009: Clinic Sheetrock & Taping Starts 16

Inc e ntive Inc e ntive – –Pre Construc tion Pre Construc tion Bidder Participation For MEP Trades Incentive One Bidder Minimum Per One Bidder Minimum Per • Package For Every Bidder over Minimum • Contractor Receives $6K Incentive For All Other Trades One Bidder Minimum Per • Package For Every Bidder over Minimum • Contractor Receives $2K Incentive Inc e ntive Inc e ntive – –Pre Construc tion Pre Construc tion Target Cost & Complete Buyout Incentive Total Construction Cost at Bid Must be Between Anticipated Contract Value C t t V l ($175M) + 2% or -5% 17

Inc e ntive Inc e ntive – –Pre Construc tion Pre Construc tion . . . And If Target Cost & Complete Buyout Total Cost at Bid Total Cost at Bid Incentive At end of Construction Then Scope Gap COs less than .5% Complete Complete + Buyout Incentive Constructability Achieved Omission COs less than .5% Be ne fits Be ne fits Greatest benefit is Accurate Buy-out at Target Cost • a successful project a successful project Improved Schedule Performance Improved Schedule Performance • • for the entire team Greatly Reduced Risk of Claims • Improved Design Process • Improved Risk Management • Process During Construction Improved Communications With • Stakeholders Decrease in RFI’s and Submittal • Turn Around Faster Decision Making • 18

Be ne fits Be ne fits Greatest benefit is Cost Control from Beginning via • Integrated Team teg ated ea a successful project a successful project for the entire team Everybody’s ideas contribute • Early Integration of Installation • Criteria Lowered Risk for Owner Constructability Resolved Early Constructability Resolved Early • During Design Stages Predictability of Planning • Fewer Surprises Improve me nts Improve me nts Bring on CM/GC During What To Do • development of BOD Differently Differently Design build subs at the D i b ild b t th • beginning of Schematic Next Time design Further develop Incentive • Plan to include smaller subs and expand into design phase design phase Use Lean during Design • phase Content of Building • Information Model 19

Ke ys to Suc c e ss Ke ys to Suc c e ss • Everybody Part of the Solution & Outcome Solution & Outcome • Culture of “How Can We…” • Consensus Building • Owner Driven IPD Process UCSF Ca rdiova sc ula r Re se a rc h Building Inte g ra te d Proje c t De live ry a nd L Inte g ra te d Proje c t De live ry a nd L e a n Proc e ss e a n Proc e ss 20

Recommend

More recommend