Automotive Council – Business Environment & Skills Group

Automotive Council – Business Environment & Skills Group

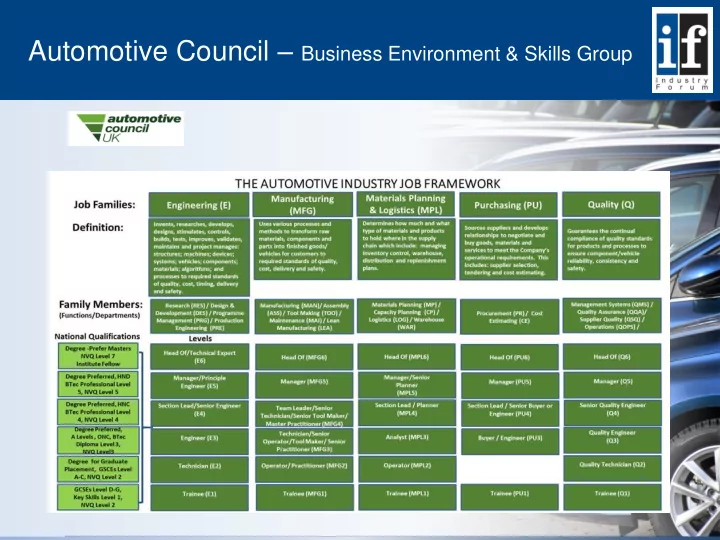

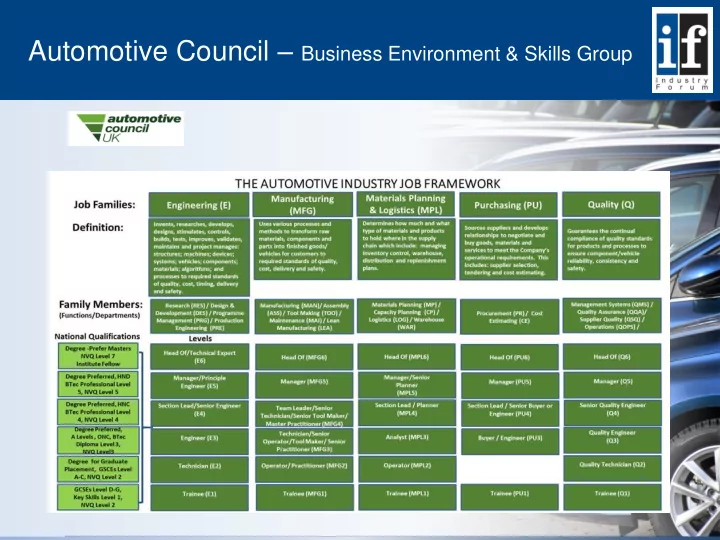

Automotive Council – Business Environment & Skills Group Job roles Competencies

Automotive Council – Supply Chain Group Chaired by Dave Allen, Jaguar Land Rover • 39 members from across the UK automotive spectrum • 5 work streams: 1. Quantifying and capitalising on business opportunities for the UK supply chain BEIS 2. Improving supply chain long-term competitiveness Chris Owen, SMMT IF Satisfying supply chain demand – Inward investment 3. Lawrence Davies, AIO 4. Finance for growth Mike Mychajluk, JLR and Richard Hill, RBS 5. Improving innovation and premium product manufacturing in the supply chain Chris Owen, SMMT IF “Building consensus, addressing the challenges”

Supply Chain Group - New Product Launch Excellence (NPLX) What is it • New Product Launch Excellence (NPLX) is a national programme aimed at improving the New Product Introduction (NPI) capabilities of the UK supply chain through the provision of essential skills, training, coaching support and project management expertise. Benefits of NPLX • The NPLX programme up-skills suppliers and provides the catalyst for dramatic improvements in new product launch capability • The programme supports IATF16949:2016 standard which mandates effective NPI processes and competently trained practitioners • Regional training and coaching waves provide convenient local venues with opportunities for best practice sharing • Cost effective solution due to leveraging national volume across OEMs and tier ones Programme Structure • Modular curriculum designed around specific business environments and operational roles. • Blended learning approach incorporating classroom training and on-site coaching/mentoring

Supply Chain Group - New Product Launch Excellence (NPLX) Module 0 Module 1 Module 2 Module 3 Module 4 Management NPI Design & Manufacturing Managing Awareness Programme Develop Process Design Product & Job Role: Management Product & Development Quality Job Role: Job Role: Job Role: Job Role: Senior management NPI project Product Production eng. Quality Duration manager designers & & quality assurance Duration: Duration 2 days developers assurance Duration Duration: 5 days 3 days 4 days 4 days Module 5 Module 6 Module 7 Module 8 Module 9 Intro. to Lean & Material Manufacturing Introduction to On-Site Value Stream Planning & Process NPLX Coaching Job Role: Job Role: Mapping Logistics Validation Job Role: Job Role: Job Role: Leadership & NPI team Duration Production eng. Purchasing, Production and heads of dept. Duration: & supply chain planning and maintenance 1 to 3 days Duration management logistics 2 days Duration: Duration: 3 days 2 days 2 days 24 topics organised into 8 training modules with on-site coaching

Supply Chain Group – Improving supply chain competitiveness (LTASC) “improved productivity “The activity will significantly increase the through better process The Supply Chain export revenues and has resulted in the definition and process creation of 38 new jobs to date (in the UK), improvement” with more planned in the future” “Revised plant “Further recruitment is layouts that will underway as per schedule Increased optimize production that will fully utilise the productivity operations” new equipment on several projects that will start in Total 3.6 : 1 private : “ Innovative processes to the New Year” invested public investment improve manufacturing £75m leverage ** enables us to optimise the “Delivering 'micro -hybrid' vehicle efficiency of our machines functionality, improved fuel 73 Manufacturers and explore more innovative economy, reduced CO 2 emissions engaged – Small, configurations” and improved air quality” medium & large “We have actually recruited an “we have > 5,000 jobs < £6,500 additional 25 direct operatives established a per job ** created & since the start of Q2 2016 and world class safeguarded * have implemented a 3 shift expertise in the system (previously we use of dynamic > 2000 people operated on days and night measurement” trained & shift)” developed Innovative Increased manufacturing capacity “The application of Lean “This much enhanced processes Manufacturing techniques New product offering has across all production areas products to made a step change in market to deliver improved the attractiveness of utilization and the suite of products” consequential cost savings” * Actuals & forecasted ** LTASC II programme

Supply Chain Group – Improving supply chain competitiveness (NMCL)

Supply Chain Group – Improving supply chain competitiveness (NMCL)

BREXIT challenge summary Key uncertainties Impact & implication 1 • Loss of confidence by Trade tariffs manufacturers [1] • Forecasted manufacturing 2 investments on the decline [2] [3] Access to skilled labour • Supply chain costs - Transparency • Concern over export 3 competitiveness Currency shifts • Lead times, inventory management • Skilled workforce capabilities, now 4 and future – Particularly STEM Customs & logistics • Labour capability and cost Ref. 1 EEF Business Confidence Rankings 29 th July 16, Ref 2. Institute of Chartered Accountants 7 th September, Ref. 3 British Chambers of Commerce 12 th September

THANKYOU

Recommend

More recommend