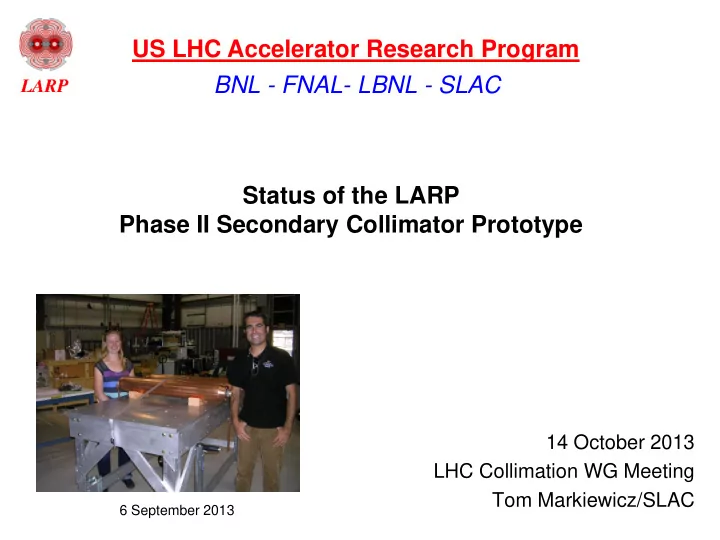

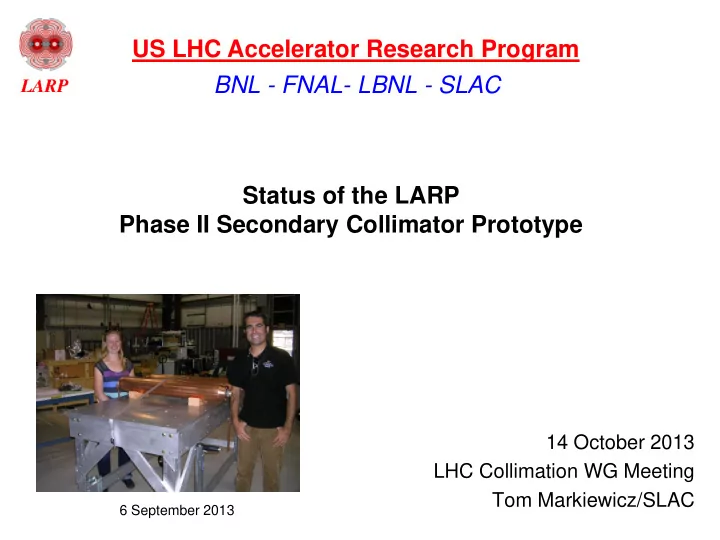

US LHC Accelerator Research Program BNL - FNAL- LBNL - SLAC Status of the LARP Phase II Secondary Collimator Prototype 14 October 2013 LHC Collimation WG Meeting Tom Markiewicz/SLAC 6 September 2013

Collimator Assembled 13-Mar-11 Mechanical & Resistance Tests Good Slide n ° 2 / 20 LHC Collimation WG Mtg - 14 Oct 2013 LARP RC Status - T. Markiewicz

Collimator Assembled 18-Sept-13 Mechanical & Resistance Tests Good Slide n ° 3 / 20 LHC Collimation WG Mtg - 14 Oct 2013 LARP RC Status - T. Markiewicz

Jaw Designed to Minimize Thermal Distortion 1 hour beam→12kW with 10 second transients x5→60kW • Continuous 15m copper tube wrapped on copper mandrel • Tube enters from far end of mandrel then begins spiral to provide ~1m free length that can twist to allow rotation • 25mm thick Glidcop “jaw” brazed to mandrel • 20 “20mm wide facets” 25um flat are the collimating surfaces • Molybdenum shaft with 2mm “heat expansion gap” from mandrel • Mandrel held at midpoint only by a brazed Glidcop “hub” Slide n ° 4 / 20 LHC Collimation WG Mtg - 14 Oct 2013 LARP RC Status - T. Markiewicz

New Bearing Restraint “Naked” Hub Screwed to Axle Bearing on Hub Spacer Ring & Bearing in Housing Bearing Restraint Ring, Bearing in Housing & Clip Oversize Outer Housing w/ Flats that prevent rotation in jaw supports Slide n ° 5 / 20 LHC Collimation WG Mtg - 14 Oct 2013 LARP RC Status - T. Markiewicz

New RF Bearing Assembly Ceramic bearing in race Assembled bearing package Trapped bearing in ring that is & the 2 rings that capture it that will hold the RF Foil fixed to the collimator jaw Attaching outer ring to collimator Close-up of ridge Before outer ring screwed on where bearing rolls Slide n ° 6 / 20 LHC Collimation WG Mtg - 14 Oct 2013 LARP RC Status - T. Markiewicz

Final RF Bearing Installed Slide n ° 7 / 20 LHC Collimation WG Mtg - 14 Oct 2013 LARP RC Status - T. Markiewicz

BeCu Foils, R hodium plate “wipers”, Clamps to keep RF Bearing Package from Dragging Holder w/Wiper/Foil Attached Foils, wipers & clamps Thermistor/Foil/Wiper Holder Beam-side View View Behind Foil w/ Clamp ATtached Slide n ° 8 / 20 LHC Collimation WG Mtg - 14 Oct 2013 LARP RC Status - T. Markiewicz

Welding Flanges Attached to Tank Cover and Baseplate Slide n ° 9 / 20 LHC Collimation WG Mtg - 14 Oct 2013 LARP RC Status - T. Markiewicz

Dry Fit Cover to Baseplate & test Rotation w/Foils Attached Slide n ° 10 / 20 LHC Collimation WG Mtg - 14 Oct 2013 LARP RC Status - T. Markiewicz

Resistivity Test: 1 mOhm/side Slide n ° 11 / 20 LHC Collimation WG Mtg - 14 Oct 2013 LARP RC Status - T. Markiewicz

Jaw Alignment & CMM Slide n ° 12 / 20 LHC Collimation WG Mtg - 14 Oct 2013 LARP RC Status - T. Markiewicz

Final Adjustment of Actuator & Drive Wheel (relative to Inner Limit Switch) Remember to play movie Slide n ° 13 / 20 LHC Collimation WG Mtg - 14 Oct 2013 LARP RC Status - T. Markiewicz

Leak Test Cooling Tubes (most recent) Pressure & Leak Rate Left Jaw (AC) Right Jaw (BD) Slide n ° 14 / 20 LHC Collimation WG Mtg - 14 Oct 2013 LARP RC Status - T. Markiewicz

Prep & “ CuSil ” the Cooling Tube to the Bellows Feedthrough Before Slide n ° 15 / 20 LHC Collimation WG Mtg - 14 Oct 2013 LARP RC Status - T. Markiewicz

On 30 Sept Remove Return Spring to CuSil the Remaining Two Tubes Before After Leak Check Tubes Again Slide n ° 16 / 20 LHC Collimation WG Mtg - 14 Oct 2013 LARP RC Status - T. Markiewicz

Install Tank Cover, Install Thermistor Feedthrough Flanges, Simulate Weld with Vise Grips and Test Rotation Drive (1 OCT) Slide n ° 17 / 20 LHC Collimation WG Mtg - 14 Oct 2013 LARP RC Status - T. Markiewicz

Design, Fab, Install, Adjust & Test Flexure to Set Actuator Height (can always be accessed through flange openings and adjusted if needed) Slide n ° 18 / 20 LHC Collimation WG Mtg - 14 Oct 2013 LARP RC Status - T. Markiewicz

Work List After that, wind 2 nd mandrel, then ………….. Prep with strips & braze coils and inner hub/shafts to mandrels (2 of 2 done) Machine assembly round & concentric to axis at diameter to accept Glidcop jaws Machine & Cu plate Glidcop jaws Prep and braze jaws to mandrels (2 nd done 8-Apr-13) Machine facets, end features (2 nd done 28-May-13) Install RF bearing housing Begin 3-June-2-13 Install shaft support bearings and rotation drives SLAC Test prior to installation in vacuum system Prep existing vacuum base plate to receive new collimators Mount, align & test Decide details of how vacuum cover will be attached to vacuum base plate & machine appropriately SLAC? Mate cover & baseplate Test rotation after welding, pre and post vacuum Vacuum bakeout Test after bakeout Ship Slide n ° 19 / 20 LHC Collimation WG Mtg - 14 Oct 2013 LARP RC Status - T. Markiewicz

Suggested Plan That Needs More Discussion At SLAC • Clamp vacuum cover in place, attach foils & test rotate 1 facet • Weld cover, vacuum test all welds & CuSil joints • Final full facet test rotation in vacuum • Solder metric water fittings, pressure test then dry & leak test tubes again • Immobilize jaws & ship (in 2 weeks time?) At CERN • Decide whether to open vacuum seal or not • Off beam tests: • Function, metrology, impedance, vacuum • Bakeout (???) • SPS tests (???) • Hi Rad Mat Tests & Subsequent Analysis Slide n ° 20 / 20 LHC Collimation WG Mtg - 14 Oct 2013 LARP RC Status - T. Markiewicz

Recommend

More recommend