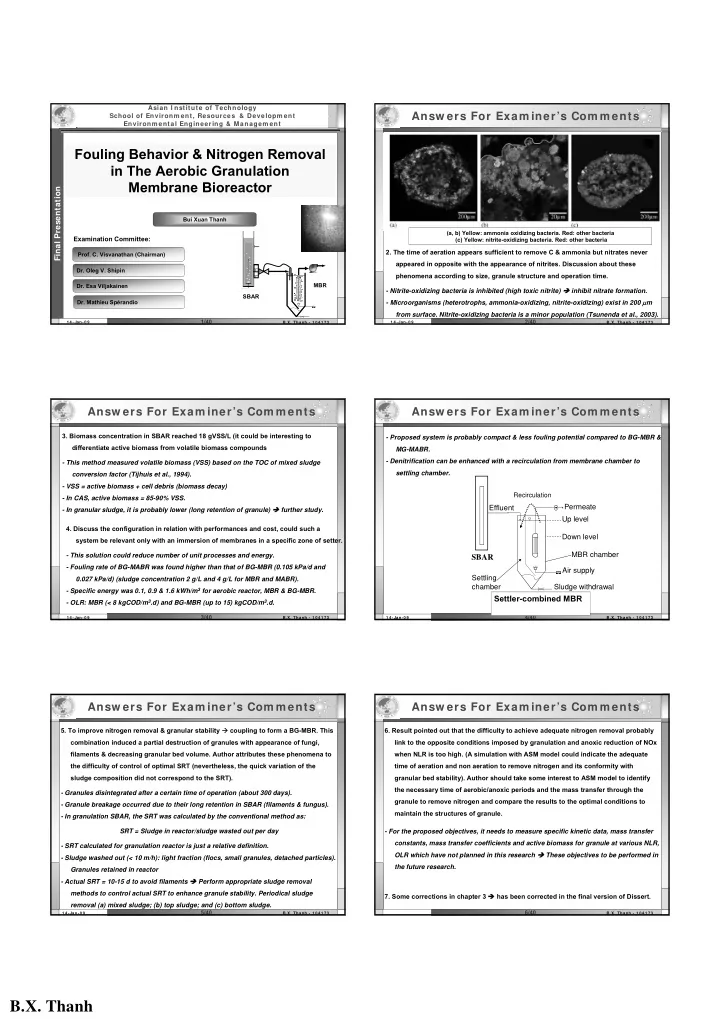

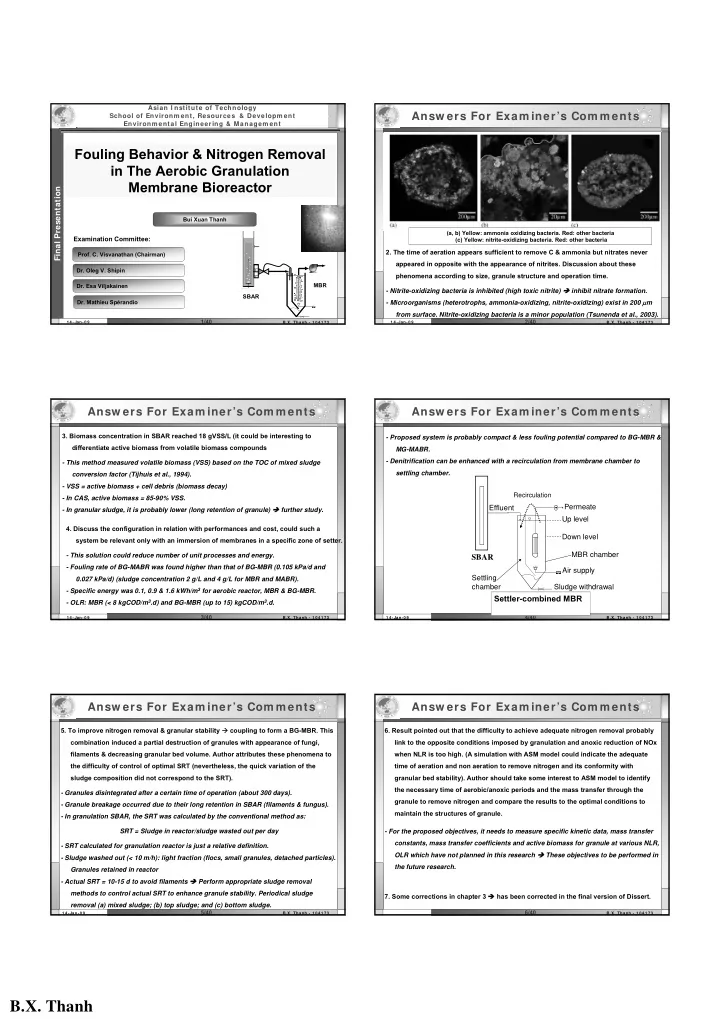

Asian I nstitute of Technology Answ ers For Exam iner’s Com m ents School of Environm ent, Resources & Developm ent Environm ental Engineering & Managem ent 1. Author should give more precision for such a choice of OLR and NLR values. After Fouling Behavior & Nitrogen Removal the reduction of NLR (but no information to justify this new choice) in The Aerobic Granulation - OLR of 2 kgCOD/m 3 .d is commonly highest designed for the CAS process in reality. - NLR of 1 kg N/m 3 .d was the high loading to investigate the maximum SND of BG-MBR Membrane Bioreactor Final Presentation without external C addition. NLR, then reduced to 0.5-0.6 N/m 3 .d to avoid effect of the pH fluctuation. - Bui Xuan Thanh (a, b) Yellow: ammonia oxidizing bacteria. Red: other bacteria Examination Committee: (c) Yellow: nitrite-oxidizing bacteria. Red: other bacteria 2. The time of aeration appears sufficient to remove C & ammonia but nitrates never Prof. C. Visvanathan (Chairman) appeared in opposite with the appearance of nitrites. Discussion about these Dr. Oleg V. Shipin phenomena according to size, granule structure and operation time. Dr. Esa Viljakainen MBR - Nitrite-oxidizing bacteria is inhibited (high toxic nitrite) � inhibit nitrate formation. SBAR - Microorganisms (heterotrophs, ammonia-oxidizing, nitrite-oxidizing) exist in 200 µ m Dr. Mathieu Spérandio from surface. Nitrite-oxidizing bacteria is a minor population (Tsunenda et al., 2003). 1/40 2/40 1 4 -Jan-0 9 B.X. Thanh - 1 0 4 1 7 3 1 4 -Jan-0 9 B.X. Thanh - 1 0 4 1 7 3 Answ ers For Exam iner’s Com m ents Answ ers For Exam iner’s Com m ents 3. Biomass concentration in SBAR reached 18 gVSS/L (it could be interesting to - Proposed system is probably compact & less fouling potential compared to BG-MBR & differentiate active biomass from volatile biomass compounds MG-MABR. - Denitrification can be enhanced with a recirculation from membrane chamber to - This method measured volatile biomass (VSS) based on the TOC of mixed sludge settling chamber. conversion factor (Tijhuis et al., 1994). - VSS = active biomass + cell debris (biomass decay) Recirculation - In CAS, active biomass = 85-90% VSS. Permeate Effluent - In granular sludge, it is probably lower (long retention of granule) � further study. Up level 4. Discuss the configuration in relation with performances and cost, could such a Down level system be relevant only with an immersion of membranes in a specific zone of setter. MBR chamber - This solution could reduce number of unit processes and energy. SBAR - Fouling rate of BG-MABR was found higher than that of BG-MBR (0.105 kPa/d and Air supply Settling 0.027 kPa/d) (sludge concentration 2 g/L and 4 g/L for MBR and MABR). chamber Sludge withdrawal - Specific energy was 0.1, 0.9 & 1.6 kWh/m 3 for aerobic reactor, MBR & BG-MBR. Settler-combined MBR Setller-combined MBR - OLR: MBR (< 8 kgCOD/m 3 .d) and BG-MBR (up to 15) kgCOD/m 3 .d. 3/40 4/40 1 4 -Jan-0 9 B.X. Thanh - 1 0 4 1 7 3 1 4 -Jan-0 9 B.X. Thanh - 1 0 4 1 7 3 Answ ers For Exam iner’s Com m ents Answ ers For Exam iner’s Com m ents 5. To improve nitrogen removal & granular stability � coupling to form a BG-MBR. This 6. Result pointed out that the difficulty to achieve adequate nitrogen removal probably combination induced a partial destruction of granules with appearance of fungi, link to the opposite conditions imposed by granulation and anoxic reduction of NOx filaments & decreasing granular bed volume. Author attributes these phenomena to when NLR is too high. (A simulation with ASM model could indicate the adequate the difficulty of control of optimal SRT (nevertheless, the quick variation of the time of aeration and non aeration to remove nitrogen and its conformity with sludge composition did not correspond to the SRT). granular bed stability). Author should take some interest to ASM model to identify the necessary time of aerobic/anoxic periods and the mass transfer through the - Granules disintegrated after a certain time of operation (about 300 days). granule to remove nitrogen and compare the results to the optimal conditions to - Granule breakage occurred due to their long retention in SBAR (filaments & fungus). maintain the structures of granule. - In granulation SBAR, the SRT was calculated by the conventional method as: SRT = Sludge in reactor/sludge wasted out per day - For the proposed objectives, it needs to measure specific kinetic data, mass transfer constants, mass transfer coefficients and active biomass for granule at various NLR, - SRT calculated for granulation reactor is just a relative definition. OLR which have not planned in this research � These objectives to be performed in - Sludge washed out (< 10 m/h): light fraction (flocs, small granules, detached particles). the future research. Granules retained in reactor - Actual SRT = 10-15 d to avoid filaments � Perform appropriate sludge removal methods to control actual SRT to enhance granule stability. Periodical sludge 7. Some corrections in chapter 3 � has been corrected in the final version of Dissert. removal (a) mixed sludge; (b) top sludge; and (c) bottom sludge. 5/40 6/40 1 4 -Jan-0 9 B.X. Thanh - 1 0 4 1 7 3 B.X. Thanh - 1 0 4 1 7 3 B.X. Thanh

Background: Aerobic Granule Rationale: Aerobic Granulation MBR • Size: 0.5–9.0 mm � Simultaneous nitrification/denitrification; Aerobic Granule! + MBR • Excellent settling ability (20-110 m/h, SVI = 18 mL/g) • Tolerate temperature range (8-55 o C) (De Kreuk et al., 2005) ; • Microbial diversity; • Remove phenol (3.8 kg/m 3 .day) ( Tay et al., 2005 ) and nitrilotriacetic (NTA) (Nancharaiah et al., 2006) Being popular due to cost reduction Water reuse and recycling; NH 4 + High SRT, MLSS & OLR � less footprint; COD But fouling, sludge treatment, and oxygen transfer. AEROBIC GRANULE Permeate & MBR? Carrier NO 3 - DO MBR Anaerobic Aerobic layer SBAR core Granule Bulk liquid 7/40 8/40 1 4 -Jan-0 9 B.X. Thanh - 1 0 4 1 7 3 1 4 -Jan-0 9 B.X. Thanh - 1 0 4 1 7 3 Objectives of Study Overall Experim ental Plan Aerobic Granulation MBR 1. Study on organic removal and simultaneous nitrification Phase II ( AIT) Phase I a ( AIT) Phase I b ( INSA)* denitrification of aerobic granule and its stability in SBAR; Batch granulation MBR SBAR Continuous granulation MBR 2. Characterize the fouling behavior of an external submerged (BG-MBR) (CG-MBR) MBR treating granulation SBAR effluent (BG-MBR) ; SBAR + Granule stability; + Effect of aeration rates Settler ( conventional vs granulation ) + Effect of OLR on fouling, 3. Study on granule stability and fouling propensity of the + Effect of anoxic/aerobic N removal Continuous Granulation MBR (CG-MBR) at various organic condition on sludge/effluent MBR of SBAR loading rate (OLR); + C, N removal + Granule characterization + Granule stability + Fouling behavior *INSA = Institut National des Sciences Appliquées, Toulouse, France 9/40 10/40 1 4 -Jan-0 9 B.X. Thanh - 1 0 4 1 7 3 1 4 -Jan-0 9 B.X. Thanh - 1 0 4 1 7 3 Batch Granulation MBR ( BG-MBR) : Phase I a BG-MBR: Lab Scale System s Feed tank SBAR: Level High aeration: 1.7 cm/s P controller Low Aeration: 0.1 cm/s Permeate NLR: 0.6-1 kgN/m 3 .d Air flow OLR: 2 kg/m 3 .d meter Shell carrier SBAR MBR Supernatant Hollow fibre, PE PLC SBAR membrane area 0.42 m 2 MBR PG MBR: Air flow: 0.3 cm/s Flux: 2.8 L/m 2 .h Timer HRT: 3.4 h Settler SRT: 20 d Air supply Suction: 7on/3off Suction Cycle (4 hrs) Feeding High Aeration Low Aeration Settling Withdrawal pump Time (min) 6 198 30 3 3 11/40 12/40 1 4 -Jan-0 9 B.X. Thanh - 1 0 4 1 7 3 B.X. Thanh - 1 0 4 1 7 3 B.X. Thanh

Recommend

More recommend