Assembling Assembling Nanomaterials Nanomaterials Richard W. Siegel Rensselaer Nanotechnology Center Rensselaer Nanotechnology Center Rensselaer Polytechnic Institute Rensselaer Polytechnic Institute Korea -U.S. NanoForum 14 October 2003 Seoul, Korea

The Materials World The Materials World materials biology chemistry physics “Those who control materials control technology” Eiji Kobayashi, Panasonic Rensselaer Nanotechnology Center Rensselaer Nanotechnology Center Administration R.W. Siegel, Director Nanostructures Nanocomposite Nanomaterials for & Nanodevices Materials Biotechnology Computational Management & Modeling & Socioeconomic Design Implications Founded April 2001 Founded April 2001

Nanotechnology Sponsors at Rensselaer Nanotechnology Sponsors at Rensselaer National Science Foundation Eastman Kodak Natick Soldier Center U.S. Army U.S. Department of Energy State of New York Sources of Funding in the Sources of Funding in the Rensselaer Nanotechnology Center Rensselaer Nanotechnology Center Sources of Funding for the Rensselaer Nanotechnology Center annual funding ca. $6 million RPI 8% NY State 8% NSF 33% Industry 16% Other Federal 35%

Nanoscale Science and Engineering Center for Directed Assembly of Nanostructures www.rpi.edu/dept/nsec Industry Partners ABB K-12 Programs Undergraduate Colleges Albany International Morehouse IBM Mount Holyoke Eastman Kodak Smith Spelman Philip Morris Williams New York State Distance-learning Visiting Researchers Rensselaer Polytechnic Institute University of Illinois at Urbana-Champaign Founded September 2001 Founded September 2001 Why Directed Assembly? Why Directed Assembly? nanoscale building blocks atoms synthesis nanotubes nanoparticles layers fundamental gateway assembly to the eventual success of nanotechnology nanostructured materials and devices dispersions dispersions high surface high surface functional functional consolidated consolidated and coatings and coatings area materials area materials nanodevices nanodevices materials materials applications in our macroscopic world http://www.nano.gov/

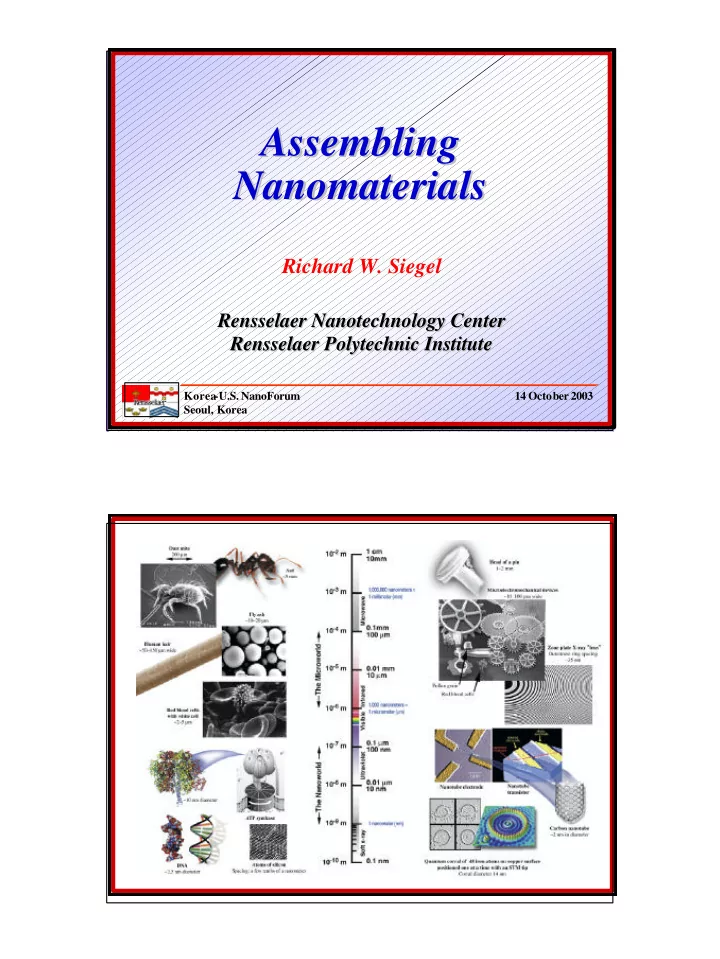

What is special about What is special about nanoscale nanoscale building blocks? building blocks? � Size confinement � High surface area � Many interfaces What is special about What is special about nanoscale nanoscale building blocks? building blocks? � Size confinement � High surface area � Many interfaces

NSEC research thrust 1 projects Nanoparticle Synthesis (Benicewicz , Braun, Moore, Siegel) - organic and inorganic particles - chemically heterogeneous surfaces 10 nm Phase Behavior of Nanoparticle-Polymer Mixtures (Schweizer, Zukoski) - study scattering and rheological properties - provide comparison to modeling efforts - provide understanding for novel assembly Polymer Nanocomposites (Lookman, Schadler, Siegel) - explore effects of novel nanoparticle fillers (isolated particles, strings, clusters) - tailor interface between filler and polymer matrix - assemble multifunctional nanocomposites 1 mm Directed Assembly of Nanostructured Materials (Lewis, Schadler, Zukoski) - design concentratednanoparticle gels for direct-writing - fabricate polymernanocomposites with hierarchical 1mm features 3-D lattice Nanoparticle Nanoparticle-assembled TiO assembled TiO 2 microtubes microtubes 100 nm 1 µm 6 µm 350 nm Ma, Siegel, Schadler (2003)

Controlled assembly of nanotube Controlled assembly of nanotube arrays arrays Vertical and Horizontal Nanotube pillars 50 µ m Wei, Vajtai, Jung, Ward, Zhang, Ramanath, Ajayan (2002) d Si SiO 2 islands Funded by ONR and the MARCO Interconnect Focus Center (Collaboration with Motorola) Carbon nanotube interconnects Ajayan, Wei, et al. (2003) 2 µ m

Creating single Creating single-wall nanotube junctions wall nanotube junctions e-beam welding Terrones, Banhart, Ajayan et al. (2002) Future Funded by the MARCO Interconnect Focus Center Carbon nanotube gas breakdown sensor 500 500 500 Koratkar , Ajayan et al., Nature (10 July 2003) 450 450 450 Current discharge (micro -amperes) Current discharge (micro -amperes) Current discharge (micro -amperes) Al: Cathode Al: Cathode Al: Cathode Al: Cathode 400 400 400 150 µ m 150 µ m 150 µ m 150 µ m C 350 350 350 A MWNT Film MWNT Film MWNT Film MWNT Film (Anode) (Anode) (Anode) (Anode) 300 300 300 Si0 2 Si0 2 Si0 2 Si0 2 250 250 250 Cathode 200 200 200 Al: Cathode Al: Cathode Al: Cathode Al: Cathode 150 µ m 150 µ m 150 µ m 150 µ m 150 150 150 s s a o r G l a t Al: Anode Al: Anode Al: Anode Al: Anode u l s 100 100 100 n i 5 0 5 0 5 0 0 0 0 200 200 200 400 400 400 600 600 600 800 800 800 1000 1000 1000 1200 1200 1200 MWNT Film Potential difference across electrodes (volts) Potential difference across electrodes (volts) Potential difference across electrodes (volts) Anode 600 B CO2 O2 NH3 I I I He 500 Discharge Current (micro-amperes) Air Ar I I I N2 400 Al plate Al plate Al plate Al plate Al plate Al plate 300 V V V 200 Si Substrate Si Substrate Si Substrate Si Substrate Si Substrate Si Substrate 100 Glass Insulator Glass Insulator Glass Insulator Glass Insulator Glass Insulator Glass Insulator MWNTs (30 micron) MWNTs (30 micron) MWNTs (30 micron) MWNTs (30 micron) MWNTs (30 micron) MWNTs (30 micron) 0 100 150 200 250 300 350 400 450 Breakdown Volatge (Volts)

Attachment of Au nanoparticles Attachment of Au nanoparticles to N to N-doped doped CNTs CNTs o o o o o o o o o o o o n o o gold + o N H 2 SO 4 /HNO colloid o o o o o 3 o o o o o o o o o o o o o o o o Functional groups are attached along the lengths and ends of N-doped carbon nanotubes (CNT). These become the sites for selective Au nanoparticle attachment. Jiang, Eitan , Schadler, Ajayan, Siegel, et al. (2003) 50 nm Funded by US Army Natick Soldier Center Polymer Polymer nanocomposites nanocomposites ♦ Control Filler Properties − particle size − shape (spheres, nanotubes…) − interface chemistry/functionality − connectivity d * isolated species * chains 2R * aggregates R g > R > d < 1 nm ~ − filler volume fraction Goal: Design composites Issues: with tailored properties - Dispersion/miscibility - Mechanical - Interface mechanics - Optical - Polymer properties change - Electrical... due to filler

Mechanical behavior of filled and neat PMMA Comparison between micron Comparison between micron-size and size and nanoscale alumina fillers in PMMA nanoscale alumina fillers in PMMA 80 NEAT PMMA 70 PMMA + 5 wt% micron-size alumina 60 Stress (MPa) 50 40 PMMA + 5wt% nano-alumina 30 20 10 0 0 0.05 0.1 0.15 0.2 0.25 0.3 0.35 0.4 0.45 0.5 Strain (mm/mm) Ash, Schadler, Siegel (2002) Ash, Schadler, Siegel (2002) Polymer nanocomposites Polymer nanocomposites – assembly and properties assembly and properties 500 16.7 wt% nano-alumina 40 500 40 Nano-alumina filled gelatin Scratch width ( µ m) Scratch depth ( µ m) filled gelatin 400 400 35 Scratch Width, µ m 35 Scratch Depth, nm 300 300 30 30 200 25 200 50 wt% nano-alumina 25 20 100 100 20 Chen, Schadler, Siegel, Irvin (2002) 0 1 2 3 4 5 0 10 20 30 40 50 Weight Percent of Refined Al 2 O 3 in 5wt% Deionized Gel Solution Weight % alumina c

LDPE / ZnO nanocomposite 1 µ m SEM of 50 wt% ZnO in LDPE Hong, Schadler, Siegel, Mårtensson (2002) Resistivity Resistivity of of ZnO ZnO/LDPE /LDPE nanocomposites nanocomposites Conduction mechanisms: PE / ZnO nanoparticles (49nm) 22 10 kV/cm 10 PE / ZnO micron particles (300nm) PE / ZnO nanoparticles (24nm) 20 PE powder / ZnO nanoparticles (49nm) 10 m) 18 10 Resistivity ( Ω 톍 16 10 Tunneling 10 14 10 12 10 10 8 10 0 10 20 30 40 50 Continuous paths ZnO Content (Vol. %) Hong, Schadler, Siegel, Mårtensson (2002)

NSEC research thrust 2 projects Preparation/Synthesis (Ajayan, Crivello) Molecular Modeling Characterization (Garde, Redondo) (Ramanath, Ajayan) Protein-Nanoparticle Biorecognition-Driven Composites Self-Assembly (Dordick, Schadler, Ajayan) (Wong, Lu, Dordick, Siegel) Tissue Engineering/Biosensing (Bizios, Siegel, Dordick) Potential applications of biocatalytic nanocomposites Potential applications of biocatalytic nanocomposites � Catalysts � Chromatographic packings � Biocatalytic membranes � Non-fouling coatings and paints • Protein, lipid, polysaccharide resistant • Microbial resistant • Sessile invertebrate resistant � Non-clogging drain pipes � Implantable medical devices � Microelectronics and microfabrication

Recommend

More recommend