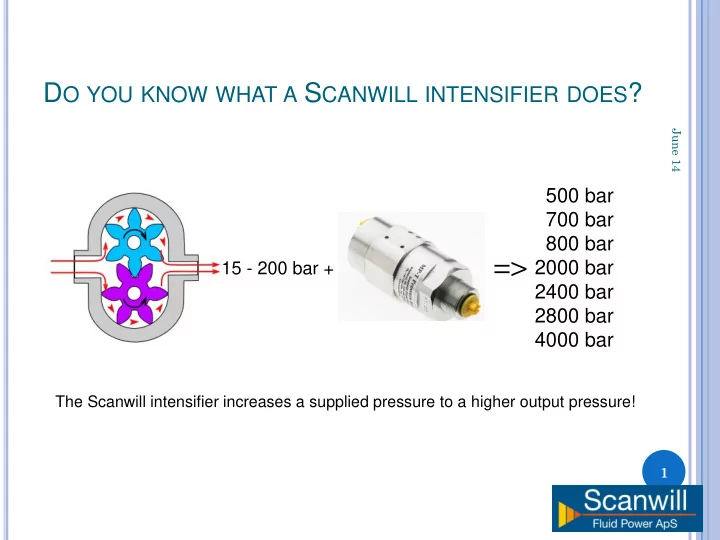

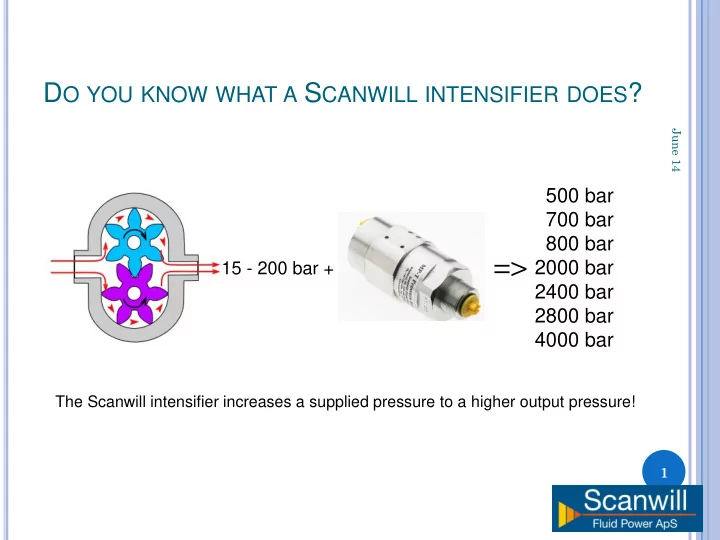

D O YOU KNOW WHAT A S CANWILL INTENSIFIER DOES ? June 14 500 bar 700 bar 800 bar => 2000 bar 15 - 200 bar + 2400 bar 2800 bar 4000 bar The Scanwill intensifier increases a supplied pressure to a higher output pressure! 1

H OW CAN WE ACHIEVE A HIGH PRESSURE ? Most Commonly Used Solution: The Future Energy Saving Solution: June 14 Standard High Pressure Pump Scanwill Pressure Intensifier 2

T HE BASIC PRINCIPLE OF A S CANWILL INTENSIFIER June 14 Inlet – low pressure Outlet – high pressure The intensifier function as a small “piston pump” in the system and will constantly deliver flow until the output pressure has been reached. 3

S CANWILL ADDED VALVES AND MADE A COMPACT DESIGN June 14 Piston speed up to 20 Hz. Hydraulically controlled only! 4

T HE BASIC PRINCIPLE & THE GENERAL FLOW - PRESSURE CURVE June 14 Add-on feature from intensifier! Intensifier output pressure equals ratio multiplied by the 5 differential pressure between P & T (P minus T)!

T HE EXTENDING & RETRACTING CYCLE OF S CANWILL INTENSIFIERS June 14 6

S CANWILL INTENSIFIERS TECHNICAL DATA June 14 Material: Cast Iron & Steel (Option: Stainless Steel) Surface Coating: Chromite Blue Finish Minimum inlet flow: MP-T, MP-C, MP-F & MP-2000: 2 LPM MP-M: 7 LPM MP-L: 15 LPM Minimum inlet pressure: 15 bar -10 ° C to 100 ° C Temperature Range: Filtration requirement: Minimum 10 micron nominal Fluids: Standard hydraulic oils Water glycol (min. 5% glycol) Water (stainless steel units only) Factory tests – before surface coating/after surface coating 7 Functionality test:

F.A.Q. ABOUT S CANWILL INTENSIFIERS Is the intensifier a pump? No! June 14 Does the T-port need to be connected? Yes, or it will not oscillate. Can intensifiers operate on fluid ”X”? If standard hydraulic components are used - then yes! However always ask if special sealing material is required (EPDM, Viton etc.). If it is aggressive fluids check with Scanwill. Can intensifiers be used for reducing the pressure and/or flow? No! Will the intensifiers operate on gas? No! Can the intensifiers be traced? Yes, they are all stamped with a 8 unique serial number.

A PPLICATION : W ORK HOLDING O UTPUT PRESSURE : 250 – 500 BAR June 14 9

A PPLICATION : H YDRAULIC M INING E QUIPMENT O UTPUT PRESSURE : 300 – 800 BAR June 14 10

A PPLICATION : H YDRAULIC P OWER P ACKS O UTPUT PRESSURE : 500 – 2,500 BAR 2,000 bar June 14 700 bar 1,400 bar 800 bar 11

A PPLICATION : B OLT T ENSIONING O UTPUT PRESSURE : 1,300 – 2,500 BAR June 14 12

A PPLICATION : H YDRAULIC R OUGHNECKS O UTPUT PRESSURE : 500 – 700 BAR June 14 Hydraulic Blocks 13

A PPLICATION : D EMOLITION T OOLS O UTPUT PRESSURE : 500 – 2,800 BAR Handheld Demolition Concrete Bursting 1,500 – 2,800 bar June 14 Tools 500 – 700 bar Excavator Tools 700 bar 14

A PPLICATION : F ILTER P RESSES O UTPUT PRESSURE : 500 – 700 BAR June 14 Bypass circuit for high flow applications: 15

A PPLICATION : H YDRAULIC T OOLS O UTPUT PRESSURE : 500 – 700 BAR Cable Tools Cutting Tools June 14 ROV Tools 16 Intensifier panels!

A PPLICATION : BEARING & WHEEL ASSEMBLY O UTPUT PRESSURE : 2,500 – 4,000 BAR June 14 700 bar 17

A PPLICATION : H YDRAULIC T ESTING O UTPUT PRESSURE : 300 – 2,000 BAR Landing gear testing June 14 High Pressure Testing (A380 @12 mio. cycles) Cylinder testing 18

S CANWILL I NTENSIFIERS IN S HORT … Characteristics Advantages Benefits June 14 High pressure precisely Low operating pressure Energy savings for the where needed in the system total system High pressure by low Use existing installed No need of expensive pressure pump pump hp components Low pressure in most Longer life of hydraulic Cost savings by places components maintenance Low pressure supply to Use standard tubing, Less cost for the total intensifier hoses & valves system & higher safety Intensifiers are compact Easy to accommodate Cost savings by components where needed installation Intensifier fitted directly No need for extra tubing Cost & space savings to cylinder or special parts by installation Just add Scanwill Use existing equipment Cost savings by intensifier for the new task installation Built-in bypass valve Full flow available at Fast operation until high 19 pump pressure pressure is reached

Recommend

More recommend