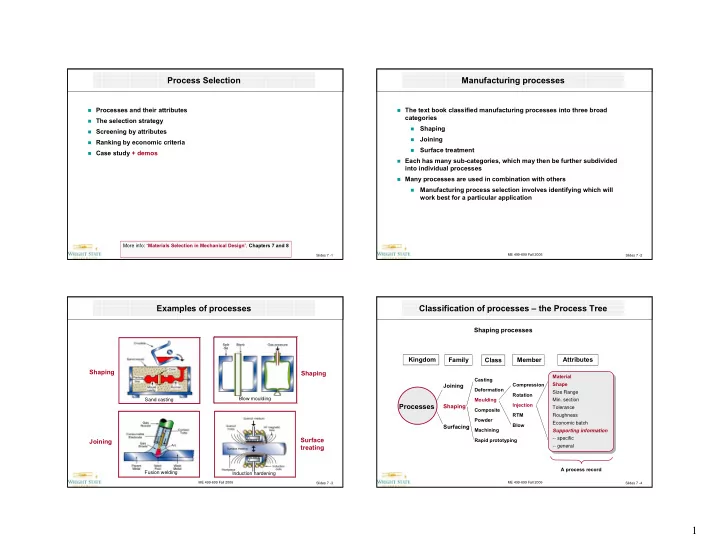

Process Selection Manufacturing processes � Processes and their attributes � The text book classified manufacturing processes into three broad categories � The selection strategy Shaping � � Screening by attributes Joining � � Ranking by economic criteria Surface treatment � � Case study + demos � Each has many sub-categories, which may then be further subdivided into individual processes � Many processes are used in combination with others Manufacturing process selection involves identifying which will � work best for a particular application More info: “ Materials Selection in Mechanical Design ”, Chapters 7 and 8 ME 499-699 Fall 2006 ME 499-699 Fall 2006 Slides 7 -1 Slides 7 -2 Examples of processes Classification of processes – the Process Tree Shaping processes Kingdom Family Member Attributes Class Shaping Shaping Material Material Casting Shape Compression Joining Shape Deformation Size Range Rotation Size Range Blow moulding Moulding Sand casting Min. section Min. section Processes Injection Shaping Tolerance Composite Tolerance RTM Roughness Roughness Powder Economic batch Blow Economic batch Surfacing Machining Supporting information Supporting information -- specific Surface Joining Rapid prototyping -- specific treating -- general -- general A process record Fusion welding Induction hardening ME 499-699 Fall 2006 Slides 7 -3 ME 499-699 Fall 2006 Slides 7 -4 1

Classification of Shape Process Selection Some processes can make only simple shapes, others, complex shapes. � Like materials selection, process selection also has the same 4 basic steps All shapes � Once a material is selected, it becomes one of the constraints in process selection Prismatic Sheet 3-D Step 1 Translation: express design requirements as constraints & objectives Circular Non-circular Flat Dished Solid Hollow Step 2 Screening: eliminate processes that cannot do the job Step 3 Ranking: find the processes that do the job most cheaply Step 4 Supporting information: explore pedigrees of top-ranked candidates � Wire drawing, extrusion, � Stamping, folding, � Casting, molding, rolling, shape rolling: spinning, deep drawing: powder methods: prismatic shapes sheet shapes 3-D shapes Because there are thousands of variants of processes, supporting information plays a particularly important role ME 499-699 Fall 2006 ME 499-699 Fall 2006 Slides 7 -5 Slides 7 -6 Example of the Translation step Screening Example : Casing for a capacitance pressure sensor for use as a traffic sensor � A combination of graph, limit, and tree stages can be used to screen the process universe to reduce the choices The sensor lies across the road, covered by a rubber mat. Vehicle pressure deflects • Bar charts are better than top face, changing capacitance between top bubble charts (ranges too wide) All processes face and copper conducting strip. Limit stage Tree stage Graph stage Physical attributes Minimum Maximum Economic batch size B B 1 > B > B 2 Mass range 0.6 kg Function Casing for road-pressure sensor Ceramics Section thickness mm Tolerance mm Roughness μ m Metals Batch size Material: Al alloy Materials Constraints Shape Shape: non-circular prismatic Polymers Circular prismatic Non-circular prismatic Minimum section: 2 ± 0.025 mm Flat sheet Hybrids Dished sheet Solid 3-D Objectives Minimize cost Hollow 3-D Free variable Choice of process Screened sub-set of processes ME 499-699 Fall 2006 Slides 7 -7 ME 499-699 Fall 2006 Slides 7 -8 2

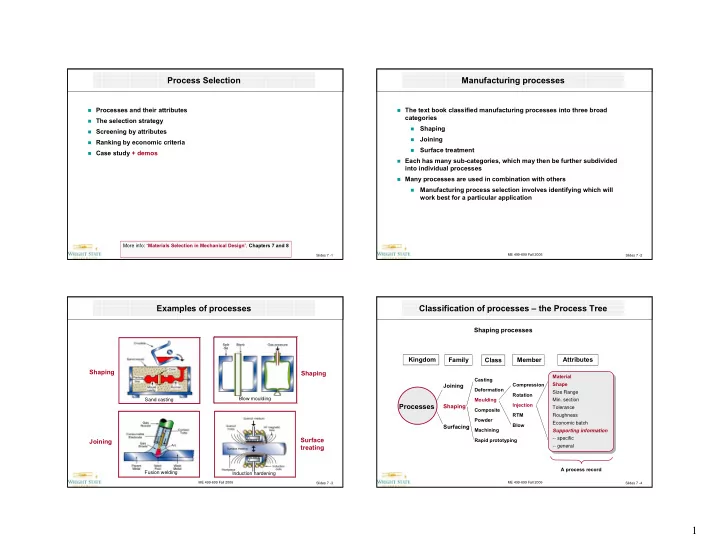

Example of the Screening step Screening: Limit and tree stages Limit � Processes for making the insulator in a spark-plug stage: Physical attributes Specification Minimum Maximum 0.05 0.06 Mass range 0.6 kg Function Electrical Insulator 3 Section thickness mm 0.5 Tolerance mm • Material class Alumina Constraints μ m 100 Insulator Roughness • Shape class 3-D, hollow Shape • Mass 0.05 kg Circular prismatic Body • Min. section 3 mm shell Non-circular prismatic • Tolerance < 0.5 mm Flat sheet < 100 μ m Dished sheet • Roughness Solid 3-D • Batch size >1,000,000 Hollow 3-D b Central electrode Objective Minimize cost Tree stage: Select CERAMIC (or Alumina) Free Choice of process Rank: bar chart for ECONOMIC BATCH SIZE . variables ME 499-699 Fall 2006 ME 499-699 Fall 2006 Slides 7 -9 Slides 7 -10 Rank on Processes based on batch size Classification of processes – the Process Tree Joining and Surface treatment processes Kingdom Family Class Member Attributes 1e+008 Economic batch size Blow Moulding Powder methods 1e+007 Material Braze Desired Material Injection Moulding Adhesives Batch Size Joint geometry Solder Joint geometry 1e+006 Sheet forming Joining Welding Size Range Gas Size Range Expanded foam molding Economic batch size (units) Section thickness Fasteners Section thickness 100000 Arc Rolling and forging Relative cost ... Relative cost ... e -beam ... Electro-discharge machining Supporting information 10000 Supporting information Processes Shaping Polymer Casting Sand casting Die Casting 1000 Heat treat Material Compression Lay-Up Material Moulding Electroplate methods Purpose of treatment Paint/print Rotational Purpose of treatment 100 Moulding Surface Anodize Coating thickness Coat Coating thickness treat Resin transfer Powder coat Surface hardness 10 Surface hardness Polish molding (RTM) Relative cost ... Metallize... Relative cost ... Texture ... 1 Supporting information Supporting information Thermoforming Rapid prototyping Process records ME 499-699 Fall 2006 Slides 7 -11 ME 499-699 Fall 2006 Slides 7 -12 3

Selection of Joining and Surface Treatment Processes The Process – Material matrix � A given process can shape, or join, or finish some materials but not others. Joining -- the most important criteria are: � A red dot indicates that the pair are compatible. � The material(s) to be joined Apply these first, � Processes that cannot shape the material of choice are non-starters. then add other constraints � The geometry of the joint � The upper section of the matrix describes shaping processes. � The two sections at the bottom cover joining and finishing. Surface treatment -- the most important criteria are: � The purpose of the treatment Apply these first, then add other constraints � The material to which it will be applied ME 499-699 Fall 2006 ME 499-699 Fall 2006 Slides 7 -13 Slides 7 -14 The Process – Material matrix The Process – Shape matrix � Shape is the most difficult attribute to characterize. � Many processes involve rotation or translation of a tool or of the work-piece. These processes make parts that have axial symmetry, or translational symmetry. � Turning creates axisymmetric (or circular) shapes; � Extrusion, drawing and rolling make prismatic shapes, both circular and non-circular. � Sheet-forming processes make flat shapes (stamping) or dished shapes (deep drawing, bending). � Certain processes can make 3-dimensional shapes, and among these some can make hollow shapes whereas others cannot. � The process-shape matrix displays the links between the two. If the process cannot make the desired shape, it may be possible to combine it with a secondary process to give a process-chain that adds the additional features: casting followed by machining is an obvious example. ME 499-699 Fall 2006 Slides 7 -15 ME 499-699 Fall 2006 Slides 7 -16 4

The Process – Shape matrix The Process – Mass-range chart � The bar-chart on the next page shows the typical mass-range of components that each processes can make. � Large components can be built up by joining smaller ones. Therefore the ranges associated with joining are also shown. � In applying a constraint on mass, we seek single shaping-processes or shaping-joining combinations capable of making ia part and reject those that cannot. ME 499-699 Fall 2006 ME 499-699 Fall 2006 Slides 7 -17 Slides 7 -18 The Process – Mass-range chart The Process – Section thickness chart � The bar-chart on the next page allows selection to meet constraints on section thickness. � Surface tension and heat-flow limit the minimum section of gravity cast shapes. � The range can be extended by applying a pressure or by pre-heating the mold, but there remain definite lower limits for the section thickness. � Limits on rolling and forging-pressures set a lower limit on thickness achievable by deformation processing. � Powder-forming methods are more limited in the section thicknesses they can create, but they may be the only ones available for ceramics and very hard metals that cannot be shaped in other ways. � The section thicknesses obtained by polymer-forming methods – injection molding, pressing, blow-molding, etc – depend on the viscosity of the polymer; fillers increase viscosity, further limiting the thinness of sections. � Special techniques, which include electro-forming, plasma-spraying and various vapor – deposition methods, allow very slender shapes. ME 499-699 Fall 2006 Slides 7 -19 ME 499-699 Fall 2006 Slides 7 -20 5

Recommend

More recommend