Water Source Application Water Source Application Water Source - PowerPoint PPT Presentation

Water Source Application Water Source Application Water Source Application & Competitor Comparison & Competitor Comparison & Competitor Comparison Content Water Source Product Selection Water Source Product Selection

Water Source Application Water Source Application Water Source Application & Competitor Comparison & Competitor Comparison & Competitor Comparison

Content � Water Source Product Selection � Water Source Product Selection � Piping Sizing � Piping Sizing � Water Cooler � Water Cooler � Competitor Comparison � Competitor Comparison

Water Source Product Selection Selection Criteria? 1. Capacity required, Total Cooling (TC), Sensible Cooling (SC) 2. Entering Air Temperature, DB/ WB 3. Entering/ Leaving Water Temperature, EWT/ LWT 4. Airflow required, CFM 5. Static pressure, Ps 5. Water Flowrate, l/s

Manual Selection & Calculation Entering Air Temperature, i. Entering Dry Bulb, EDB ii. Entering Wet Bulb, EWB Tip: DB changes while WB remains will not affect the TC. SC 2 (kW)= SC 1 (kW)+ [1.23* (l/s)* (1-BPF)* (EDB 2 -EDB 1 )/1000] Example: if TC = 3.52kW and SC= 2.78kW at EDB = 27 ° C, EWB= 19 ° C. Calculate the TC and SC when EAT is as following; EDB = 30 ° C, EWB = 19 ° C Assuming air flow rate = 180 l/s, BPF= 0.06, Water flowrate = 1.25m 3 /hr

Manual Selection & Calculation TC = 3.52kW and SC= 2.78kW EDB = 27 ° C, EWB = 19 ° C EDB = 30 ° C, EWB = 19 ° C Since WB 1 = WB 2 , then TC 1 = TC 2 = 3.52kW , and SC 2 =SC 1 + [1.23*(l/s)*(1-BPF)*(EDB 2 -EDB 1 )/1000] = 2.78+[1.23*180*(1-0.06)*(30-27)/1000] = 3.40kW

Selection & Calculation by Selection Software Download selection software from e-biz. 1. Select model type 2. Select indoor if split type was chosen 3. Chose the fan speed 4. Key in the water flow 5. Key in the on coil temperature and EWT temperature 6. Key in the designed capacity to fulfill the building heating/cooling load requirement. 7. Key in the capacity tolerance (%) 8. Click “Calculate”

Selection & Calculation by Selection Software Selection Result 9. Select the model closest to the capacity requirement

Example of Piping Sizing 1. Determine System Water Flow Rate - DON’T sum up directly the total nominal water flow of each WSHP unit. - Total System design flow rate is determined by the performance of the water cooler, where most of them are evaporative type and is very much dependent on the entering air wet bulb temperature. - Lower flow rate are preferred in areas with lower wet bulb temperatures. In more humid areas, a higher water flow rate will supply a higher water temperature to water source units, but with a lower differential.

Example of Piping Sizing 2. Determine WSHP unit flow rate - Total Cooling load must be known. - Diversity Effect must be considered. This is to prevent over sizing water cooler Diversity Factor = Block Load / Σ (Peak Load) - Recommended diversity factor; - 85% for system up to 40 tons - 80% for system between 40 and 60 tons - 75% for system greater than 60 tons - System diversity will only affect the range of the water cooler.

Example of Piping Sizing 2. Determine WSHP unit flow rate (Cont…) Range of Water Cooler, R s = T wi – T wo Where; T wi = entering water temperature T wo = leaving water temperature - By using diversity factor, D, we can then calculate the avarage range of the water source units, R p R s = D * R p Where typical value of range are between 5 ° C to 8 ° C or equally - 9 ° F to 14.4 ° F.

Example of Piping Sizing 3. Determine individual unit peak cooling load - By assuming 30% of heat rejection ratio, Total heat rejection, Q h Q h = 1.3 * D* Q c Q h = m w * C p * (T wi – T wo ) Where Total cooling peak load, Qc m w = mass flow rate of water C p = water specific heat - By replacing with known constants, we will get these familiar equations; Q h = 500 gpm (T wi – T wo )

Example of Piping Sizing 3. Determine individual unit peak cooling load (Cont…) - By having water cooler range, R s in the equation; Q h = 500 * gpm * R s - By having total peak cooling load, Qc in the equation; 1.3 * D* Q c = 500 * gpm * R s - Thus the individual unit peak cooling load, q c 1.3 * q c = 500 * gpm * R p

Example of Piping Sizing Example: A water loop system consists of 30 units of water source heat pump units with a combined total peak loading of 450,000btu/hr. the system is served by a centrifugal water pump. A closed loop water cooler is used to give a leaving water temperature of 30 ° C. the ambient air wet bulb temperature is 25 ° C. - Determine the required total system water flow rate. From the given table, at 25 ° C wet bulb temperature, the water flow rate is 2.36 gpm/ton. Therefore, the total system water flow rate is 2.36 gpm/ton * (450000/12000)ton = 88.5 gpm. - Calculate the average range of the water source units The system range is first calculated; R s = 1.3 * D * Q c / gpm / 500 = 1.3 * 0.85 * 450,000 / 88.5 / 500 = 11.24 ° F or 6.24 ° F R p = R s / D = 13.22 ° F or 7.35 ° F - If one of the water source units has been designed to give a cooling capacity of 11,000btu/hr, calculate the water flow rate required. R p = 1.3 * q c / gpm / 500 ⇒ 13.22 = 1.3 * 11000 /gpm/500 ; gpm = 2.16gpm - Recalculate if there is no diversity factor is applied. If D = 1, and maintaining the flow rate, R p = R s / D = 13.22 ° F or 7.35 ° F

Example of Piping Sizing 4. Piping Sizing - Important to ensure the selected water pump is sufficient to deliver the required water flow rate. - To do this calculation, it is important that a detailed drawing layout of all components in the system is available. - The layout should give dimensional lengths of the piping network. - Location of water cooler, pumps and boiler must be identified. - All fittings and accessories used in the piping installation should be clearly identified. - Study the pipe circuit layout and do preliminary check if the circuits are balanced. Re-arrange if necessary. Use balancing valves only if it is not possible to have balanced circuits. - Size the pipes by using the pipe chart. The water velocity should be in the range of 2 – 9 fps, with a recommended max friction loss of 10 ft of water per 100 ft.

Example of Piping Sizing 4. Piping Sizing (Cont…) - Calculate equivalent pipe length. Include the losses for all the valves and fittings used. Calculate the total pipe friction loss by using the friction loss value from the pipe chart. Add this with the pressure drop in heat exchangers, water cooler and boiler. - Select a pump which will match these total system water flow rate and total head pressure.

Example of Piping Sizing Example: The water source units which serve the main building has a total installed cooling capacity of 560,000 btu/hr (peak load). There a altogether 40 sets, with 10 sets for each of the four floors (1 st floor to 4 th floor). The water source units have been selected based upon the following conditions: Entering air = 25 ° C DB / 18 ° C WB Entering water = 32 ° C All the units are connected to an evaporative water cooler located on top of an adjoining service building outside of the main building. The outside air wet bulb temperature is at 24 ° C

Example of Piping Sizing Example: (Cont..) 1. Calculate the total system water flow rate. Total installed capacity = 560,000 btu/hr (46.67 tons) Therefore, the total system water flow rate @ 24 ° C wet bulb is 2.19 gpm/ton * 46.67 tons = 102.2 gpm. 2. Calculate the range (Rs) of water cooler For 46.67 tons, use diversity factor of 0.80. Rs = 1.3 * D * Qc / gpm / 500 = 1.3 * 0.80 * 560000 / 102.2 / 500 = 11.40 ° F or 6.3 ° C. 3. Calculate the range (Rp) of water source units. Rp = Rs / 0.80 = 11.40/0.80 = 14.25 ° F or 7.9 ° C.

Example of Piping Sizing Example: (Cont..) The unit on the 4 th floor have been sized to give the following peak 4. loads; By using equation 1.3 * q c = 500 * gpm* R p , we can then work out the flow rate through each of these units. Let assume that the total system water flow rate is distributed to all the four floors of the main building in this manner.

Example of Piping Sizing Example: (Cont..) With this, we can no look into the pipe sizing all the way up to 4 th floor. Focus is given to 5. determine the route of least favourable which will give the max friction loss to the water pump. i.e. all the way to unit q. Reference is then made to pipe chart to determine a suitable pipe size.

Example of Piping Sizing Example: (Cont..) 6. Each of the WSHP has fittings as shown in the diagram below: The water pump has been installed in this manner:

Example of Piping Sizing Example: (Cont..) Detail of water pipe connection to the evaporative water cooler is as shown below:

Example of Piping Sizing Example: (Cont..) 7. With all these fittings details and pipe lengths, we can now calculate the pipe friction loss from the water cooler to point q. This is as demonstrated in this summary table.

Example of Piping Sizing Example: (Cont..)

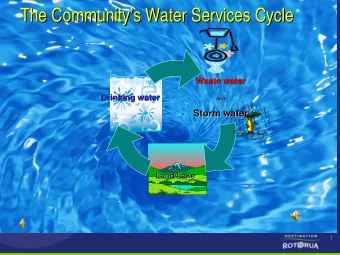

Water Cooler Type of Water Cooler Evaporation of Water to cool the condenser 1. Closed Circuit Cooling Tower 2. Open type cooling tower with heat exchanger Air Cooled 3. Dry Cooler

Water Cooler Terminology Open Cooling Tower An evaporative equipment that exposes exposes water directly to the water directly to the cooling atmosphere, cooling atmosphere thereby transferring the heat load directly into the air.

Recommend

More recommend

Explore More Topics

Stay informed with curated content and fresh updates.