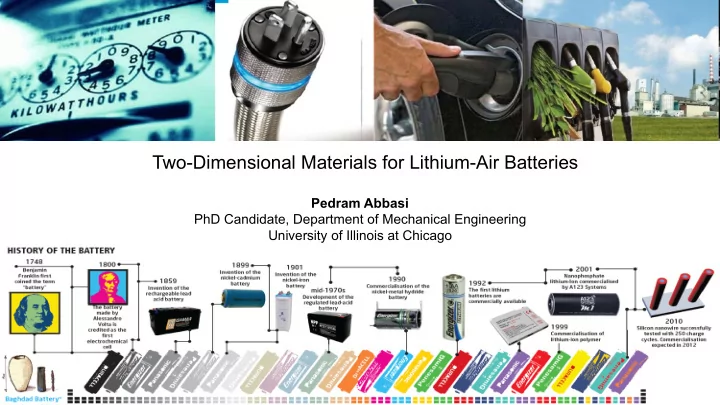

Two-Dimensional Materials for Lithium-Air Batteries Pedram Abbasi PhD Candidate, Department of Mechanical Engineering University of Illinois at Chicago

Agenda q An overview on the current states of Li-ion batteries q Motivation of research on Li-air batteries q The chemistry of Li-air systems q Challenges associated with Li-air systems q Role of two dimensional materials in Li-air batteries q Overview and outlook news.mit.edu

Current states of Li Batteries q Production of Electric Drive Vehicle (EDV) batteries has been ~ doubling globally every year since 2010. q Economies of scale continue to push costs towards $200/kWh. q New material chemistries and lower-cost manufacturing, cost parity with (Internal Combustion Engines (ICEs)) should be reached in the next ten years. Tesla’s battery pack in the floorpan of the Model S (Image: First Reporter ) High Energy density Low Price doi:10.1038/nmat3191

Advantages q Very high energy density compared to the Li-Ion q Cost Effective Kuzhikalail M. Abraham q Environmentally friendly Energy density comparison among different Metal-Air batteries First Li-air battery by Abraham 1996 Battery 500 project By IBM, 2014

How a Lithium-air battery works? 𝐸𝑗𝑡𝑑ℎ𝑏𝑠𝑗𝑜 𝑃𝑆𝑆 2𝑀𝑗 / + 2𝑓 2 + 𝑃 3 → 𝑀𝑗 3 𝑃 3 1 𝐷ℎ𝑏𝑠𝑗𝑜 (𝑃𝐹𝑆) 𝑀𝑗 3 𝑃 3 → 2𝑀𝑗 / + 2𝑓 2 + 𝑃 3 2 doi:10.1038/nmat3191

Challenges Associated with metal-air battery Side Reactions Metal Anode poisoning Electrolyte instability Cathode clogging with H 2 O and CO 2 and corrosion and decomposition and irreversible product formation • Sluggish OER and ORR • Narrow Potential window • Increasing charging potential • Difficulties in designing of an at cathode • Insufficient ionic conductivity • Poisoning the anode efficient SEI layer • Low cell efficiency • Low solubility of some desired Li- salts • Irreversible reactions • Limited cycle life • Capacity loss SEI layer engineering Electrolyte Compatibility Advanced electro catalysts and Prevention of side Reactions and anode protection and stability Tailoring the Product phase with H 2 O and CO 2 and structure SEM images of various morphologies of lithium peroxide in discharged cathode. Toroidal- Formation of SEI layer prevent the anode Role of di-electric electrolyte and salt and Potential of formation of LiOH and Li 2 CO 3 as shaped (a) spherical particles (b) elongated poisoning and dendrite formation electrolyte type the two major side-products in Li-Air batteries particles (c) close-packed nanosheets (d), rough thin films (e) and porous ball-like (f) DOI: 0.1002/aenm.201502164 doi.org/10.1016/j.jpowsour.2010.09.031

Role of 2D materials in lithium-air battery Two dimensional Li-air Electrodes Nanomaterials Advanced electro catalyst Insulating 2D materials, ionically conductive Solid-state DOI: 10.1039/c6cc05357b electrolyte SEI layer for Li-anode q High Surface to volume ratio Insulating 2D materials, High mobility 2D materials, q Tunable electronic property ionically conductive ionically conductive q Scalable synthesis methods q Cheap and cost effective High Performance air cathodes High surface to volume, High porosity

Plan for Final Report Introduction 3.TMDCs An overview on the current challenges 4.LDHs of Li-air battery 5.TMOs and TMH 1. Two-dimensional carbon based materials in metal 6.Two dimensional materials for Li-air anode air batteries protection 1.1 Porous Carbon 7.Two dimensional materials as Li-air solid state 1.2Graphene electrolyte 1.2.Functionalized carbon materials 8.Summary and conclusion 2. MXENEs

References (1) Adelhelm, P.; Hartmann, P.; Bender, C. L.; Busche, M.; Eufinger, C.; Janek, J. From Lithium to Sodium: Cell Chemistry of Room Temperature Sodium-Air and Sodium- Sulfur Batteries. Beilstein J. Nanotechnol. 2015, 6, 1016–1055. (2) Balaish, M.; Kraytsberg, A.; Ein-Eli, Y. A Critical Review on Lithium-Air Battery Electrolytes. Phys. Chem. Chem. Phys. 2014, 16, 2801–2822. (3) Kim, B. G.; Kim, J. S.; Min, J.; Lee, Y. H.; Choi, J. H.; Jang, M. C.; Freunberger, S. A.; Choi, J. W. A Moisture- and Oxygen-Impermeable Separator for Aprotic Li-O2 Batteries. Adv. Funct. Mater. 2016, 1747–1756. (4) Huff, L. A.; Rapp, J. L.; Zhu, L.; Gewirth, A. A. Identifying Lithium-Air Battery Discharge Products through 6Li Solid-State MAS and 1H-13C Solution NMR Spectroscopy. J. Power Sources 2013, 235, 87–94

Recommend

More recommend