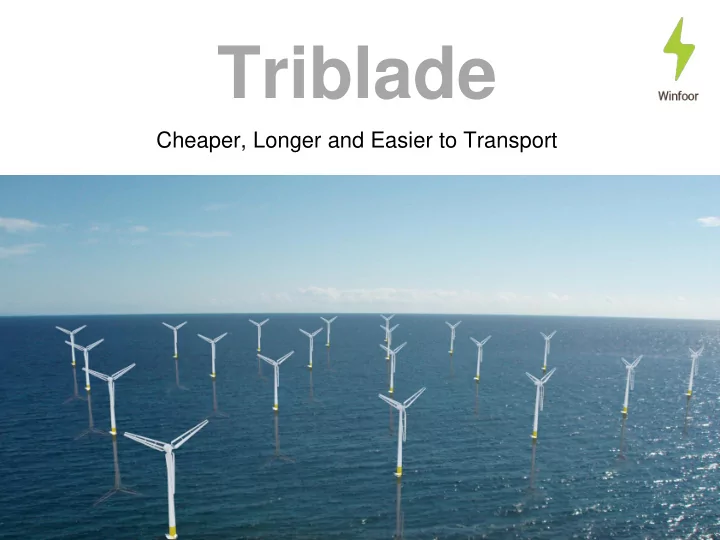

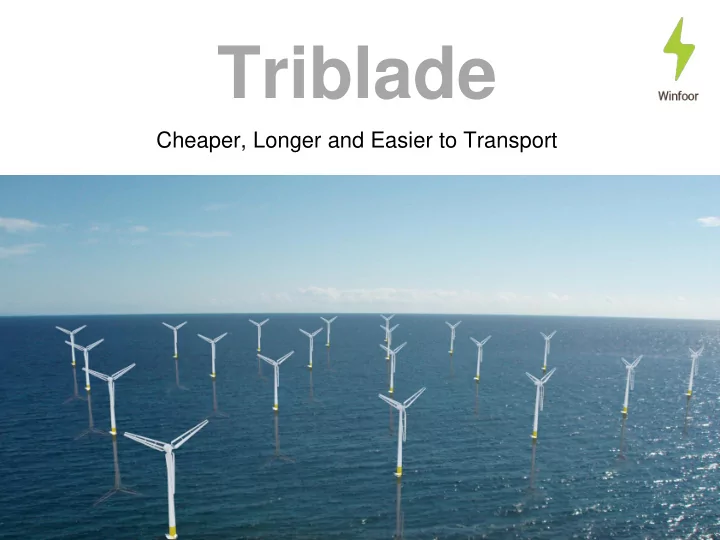

Triblade Cheaper, Longer and Easier to Transport

Who am I? • Asil Erguner – MSc. Eng. in Wind Energy, DTU – Mechanical Design Engineer in Winfoor AB

3-in-1 blade • Triblade is a 3-in-1 blade. Three slender blades are linked together by supporting structure, to form a truss. It makes it very stiff and lightweight. • The three slender blades are the ones that drive the rotor.

22m Triblade • The three slender blades are approximately parallel to each other. Each one has one third of the chord length of a standard blade. Three blades in close proximity to each other has better aerodynamic performance than a single blade. • The supporting structure is called bracing and it runs between the blades on the diagonal and perpendicular to the blades. It is there for structural reasons only. As they add to the drag, they should be as slender and streamlined as possible. • In the end, Triblade is estimated to have the same aerodynamic efficiency as a standard blade.

State of the project • We are currently building a 22m diameter Triblade rotor that will be tested on a wind turbine during 2019. Picture to the left is from our first real world demonstration. • We have so far raised in total €3.2 million for taking Triblade to the market. Funding from: • The advisory board includes several leading turbine makers and energy companies. All are not listed here due to confidentiality reasons.

22m Triblade rotor specs • Material – Blades – carbon – Bracing – steel and carbon • Rotor diameter – 22m • Expected power – up to 100 kW • Design loads – IEC2 wind class – Standstill – 60m/s from any direction – Production – 10m/s from front – Yaw error – up to 45 degrees off, 10m/s

Manufacturing at Marstrom • Making the blades.

Manufacturing at Marstrom • Vertical bracing formed as triangles.

Manufacturing at Marstrom • Assembling Triblade

Manufacturing at Marstrom • Root connection and assembly fixture

Manufacturing at Marstrom • Tip section

Manufacturing at Marstrom • 40m/s stand still load – 900kg salt bags. – 10mm tip deflection

Manufacturing at Marstrom • 1.5 times 10m/s wind speed production load – 900 kg salt bags – 20mm tip deflection

Manufacturing at Marstrom • The tip section.

Test site • Nordic Folkecenter, Jutland, Denmark. Test turbine specifications Stall regulated Fixed speed and fixed pitch Max rpm 47 Rated power 140 kW Rotation Counter clockwise Hub height 23m Mean wind speed at hub 6.2m/s Rotor diameter now 17m Triblade rotor diameter 22m • Test plan – Power production and wind speed – Noise – Different Triblade configurations – Deflection

Test turbine

Full scale 90m Triblade • The images show the load carrying structure of a full-scale Triblade, which consists of blade beams and bracing. The blade beams should be covered with airfoil shaped shells from glass fiber. • The design is based on using piece-wise straight blades. It means that in each section, the blade is dead straight, with no twisting and constant chord length. Between sections the blade beam changes discontinuously. • A great thing with this approach is that it simplifies the design and it simplifies the production.

Market research • Reducing cost of energy is top priority. • The trend is towards larger and more powerful turbines. • Up to 30 % of the cost for a large turbine is attributed to the rotor blades. – Material cost is about 60 % of total rotor blade cost. • Transportation of heavy and long blades is a major problem. • Blade production is labor intensive. • Cost and mass of rotor blades increase faster than power output when scaling up blade length.

Triblade solution • Specification – Cheaper – manufacture and transport – Modular – module size up to 12x2x1m – Lighter – much less material – Longer – 50% longer or more • Manufacturing – Smaller and flexible facilities – More automated production – Lower tooling costs • Transportation – Low weight and modular approach reduce cost. – Standard trucks and containers – Assembling at or near site of installation.

The rotor blade market • The global rotor blade market was valued at – US$ 10 billion in 2013 (MarketsAndMarkets, 2014) – projected to reach US$ 33 billion by 2025 (Persistent Market Research, 2017) • Our target customers are the large turbine makers. Half of the world’s blade production is made in-house by these companies. • The competition is working on traditional blades, with incremental improvements like active control, new materials, and optimized design. Nothing like Triblade though.

Road map • Demonstrate 22m diameter rotor • Start building full scale rotor • Demonstrate full scale rotor • Certification • Market introduction

Thank you Asil Erguner MSc. Wind Energy, Mechanical Design Engineer in Winfoor AB

Recommend

More recommend