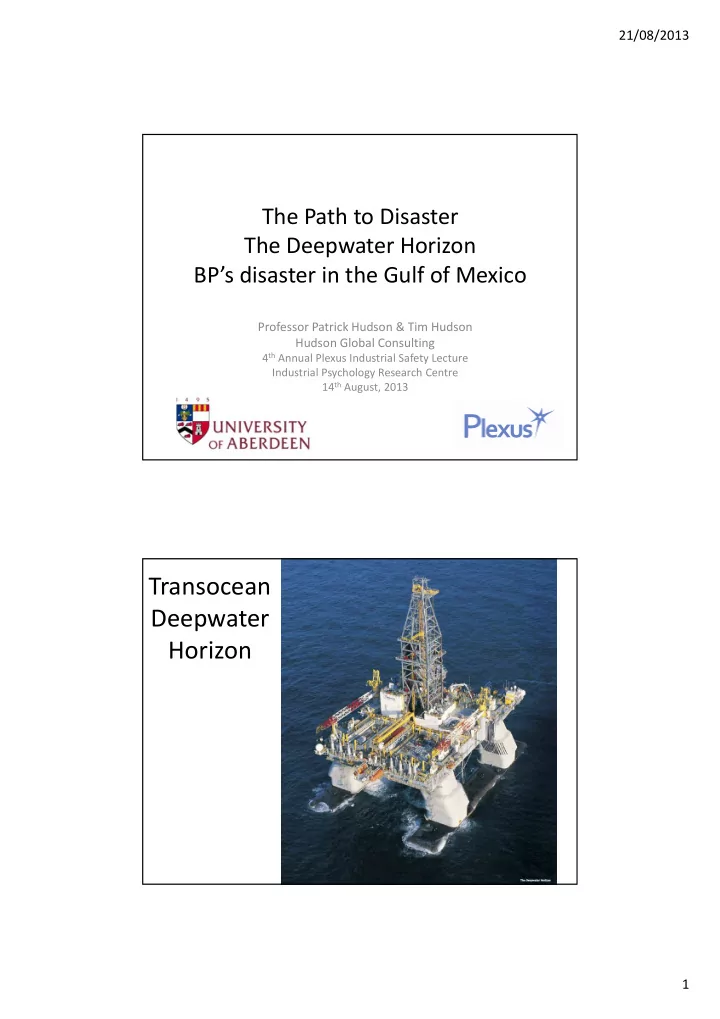

21/08/2013 The Path to Disaster The Deepwater Horizon BP’s disaster in the Gulf of Mexico Professor Patrick Hudson & Tim Hudson Hudson Global Consulting 4 th Annual Plexus Industrial Safety Lecture Industrial Psychology Research Centre 14 th August, 2013 Transocean Deepwater Horizon 1

21/08/2013 The accident • 20 th April 2010 • Hydrocarbons escaped into the well while it was being underbalanced with seawater • The Blow Out Preventer (BOP) was activated late and failed to shut in the well • The riser was not disconnected • The escaping gas ignited • 11 dead • The drilling rig Deepwater Horizon sank after 2 days 2

21/08/2013 Conclusion • The accident was preventable • If BP’s Operating Management System OMS had been applied rigorously, the temporary abandonment could have been completed safely • The dominant failures were associated with no risk analyses or assessments despite major changes and problems with the well • The primary causes can be related back to BP’s organizational culture Mississippi Canyon 252 • Original plan to produce a well for an Anadarko facility • Poor offset data – Exploration well rather than a production well • Drilled by Transocean Marianas – The Pharos from Piper Alpha • Marianas forced off in late 2009 after hurricane damage • Replaced early 2010 by Deepwater Horizon • Described as “the well from hell” 3

21/08/2013 The well Drilling Margin • Three factors to consider • Pore pressure – Formation pressure acting in on the hole • Fracture gradient – Point at which rock breaks with mud pressure • Equivalent Circulating Density – Extra pressure due to mud pump pressure 4

21/08/2013 Drilling the well 5

21/08/2013 Well Design March 8 th Dress Rehearsal • On March 8 th there was a kick (influx of hydrocarbon) • The kick was detected late – There were crane operations at the time – The Sperry-Sun mud-logger was not believed • The well was shut in successfully • Recovery required a sidetrack • Costs including rig time exceeded $10M • No MIA report was made to London • The same crew was also on board on 20 th April 6

21/08/2013 Temporary Abandonment April • Original plan to have a keeper well – to be completed for production at a later date • The well ran out of drilling margin at 18360 ft • Formation pressure 16,800 psi -1150 bar • They drilled on to get below the pay-zone • An initial plan was produced on April 12 th • Feedback was that a pressure test for integrity was missing • The decision to set the lockdown sleeve was retained • The temporary cement plug was to be set in seawater Sequence of abandonment plans 7

21/08/2013 Procedure for temporary abandonment of the well Cementing the well • Run long string 7” casing • Centralize production casing to avoid channelling • Clean out the well – bottoms up • Convert float collar • Pump spacer • Pump nitrogen foamed cement • Test well integrity – Positive pressure test – Negative pressure test 8

21/08/2013 Centralizers • Centralizers are necessary to ensure the annulus is constant, otherwise cement leaves mud behind allowing the possibility of hydrocarbon escaping through the mud • Halliburton ran its Opticem software and recommended 21 centralizers • BP eventually ran with 6 without consulting Halliburton 9

21/08/2013 Centralizers on the rig, but not used Cleaning the well • A well needs to be cleaned by circulating mud • Circulation also breaks gel that sets if the mud is left alone • Ideal and standard is 1x or 1.5x bottoms up • Extra pumping adds pressure as an increase in ECD • BP rejected the Halliburton recommendation to run a full bottoms up 10

21/08/2013 Float Collar • A float collar is a two-way valve that can be converted to a one-way valve to ensure the cement does not flow back up the casing (U- tubing) • The float collar has to be converted with a sufficient flow rate of mud • This was never achieved, but conversion was accepted because of the high pressure applied to the float collar (3142 psi) 11

21/08/2013 12

21/08/2013 Debris in the shoe Description of Event – Placement of Cement April 19 th – 20th Choke Kill Boost • 19:30 – 00:30 - Cement job pumped as planned. • 60 bbls cement • Foamed cement used to reduce risk of losses • 6 inline centralizers were spaced across the main pay BOP Sea Floor • 00:35 – 7:00 – Seal assembly installed and pressure tested, but not locked down to wellhead. Proceeded Cement Cement to preparation for positive casing test. Mud Mud • ~7:30 – Decision made not to run Cement Bond Log Spacer Spacer (CBL) premised on minimal losses and lift pressures observed during cement displacement. Seawater Seawater 14.17ppg Influx Influx SOBM Top of Cement 17260’ Shoe – 17,168’ TOC – 17,260’ 14.0ppg Cement 13.1ppg 12.6ppg FC – 18,115’ 12.6ppg Primary reservoir sands 12.6ppg Shoe – 18,304’ BP Confidential: Horizon Investigation Update 26 13

21/08/2013 Pressure Test • Positive pressure test to ascertain if the casing above the plugs will hold – Overbalance the well (i.e. pump up from above) • Negative pressure test to ascertain whether the cement barrier is effective – Underbalance the well by removing mud and replacing it with sea-water (pump out from above) – If the well is safe then there should be no change in pressure through the BOP – Proposal in MMS plan to measure on kill line rather than drill-pipe Description of Event - Positive Pressure Test 2700 PSI April 20th Choke Kill Boost • 7:00 – 12:00 - Successful positive pressure test for production casing and seal assembly. Drill pipe – Low Pressure 250 psi – High Pressure 2700 psi Closed BOP • Note: The positive test is not designed to verify Blind Ram Sea Floor integrity of the shoe track (cement and float collar). BOP Cement Cement Mud Mud Spacer Spacer Seawater Seawater 2700 psi Influx Influx 14.17ppg SOBM Shoe – 17,168’ TOC – 17,260’ 14.0ppg 13.1ppg 12.6ppg FC – 18,115’ 12.6ppg Primary reservoir sands 12.6ppg BP Confidential: Horizon Investigation 28 Shoe – 18,304’ Update 14

21/08/2013 Negative Pressure Test First Negative Pressure test 15

21/08/2013 Second Negative Pressure test Description of Event - Negative Pressure Test 1400 0 PSI PSI April 20th Choke Kill Boost Closed • Negative test designed to verify integrity of seal Annular BOP assembly, casing, and shoe track in an underbalanced Drill pipe condition. This simulates conditions for T&A and rig demobilization. • 12:00 – 15:04 - Reviewed displacement procedure BOP and commenced preparation for negative test. Sea Floor Viscous • 15:04 – 15:56 – Displaced mud with sea water to Spacer Cement Cement underbalance the well. Mud Mud • 15:56 – 16:53 – Spacer inadvertently placed across Seawater the BOP due to leaking annular. Spacer Spacer • 16:53 – 17:52 – Test started by monitoring pressure Seawater Seawater on drill pipe. Influx Influx • 17:52 – 19:55 – Negative pressure test procedure switched to monitor pressure on kill line. 14.17ppg – No pressure and no flow observed on the kill SOBM line – 1400 psi observed on the drill pipe 19:55 – T est was concluded to be successful. • Shoe – 17,168’ TOC – 17,260’ 14.0ppg 13.1ppg 12.6ppg FC – 18,115’ 12.6ppg Primary reservoir sands 12.6ppg BP Confidential: Horizon Investigation 32 Shoe – 18,304’ Update 16

21/08/2013 Description of Event - Initial Recognition of Abnormal Well Conditions April 20th Choke Kill Boost Note: the following details are largely based on Hydrocarbon interpretation of data and witness statements: Influx above 21:31 – After completely displacing the spacer out of Seawater BOP • the riser, the pumps were shut down. BOP • 21:31 – 21:34 – Rig crew discussed abnormal drill Sea Floor pipe pressure increase. Cement Cement • 21:36 – Rig crew bled the drill pipe to investigate the abnormal pressure. Mud Mud 21:38 – Hydrocarbons began to enter riser. Spacer Spacer • Seawater Seawater • 21:40 – Mud overflowed the flow-line and onto rig. 21:41 Influx Influx • 21:41 – Mud shot up through the derrick. Rig crew diverted to the mud gas separator (MGS) and shut the annular BOP. Shoe – 17,168’ TOC – 17,260’ 14.0ppg 13.1ppg 12.6ppg FC – 18,115’ 12.6ppg Primary reservoir sands 12.6ppg BP Confidential: Horizon Investigation 33 Shoe – 18,304’ Update Kick detection 17

21/08/2013 18

21/08/2013 12” Vent 6” Vacuum Breaker Bursting Disk MGS vented to MGS MGS manned and Rated to 60 psi hazardous areas Rotary Hose Mud System IBOP Starboard Hydrocarbons routed Overboard Diverter to MGS Starboard Port Overboard Diverter Line Flow Line Overboard Rated to 100 or 500 psi Slip Joint Kill Boost Choke Diverter overboard BOP lines closed System quickly overwhelmed by pressure and volume, leading to loss of containment 19

21/08/2013 Blowout Preventer (BOP) Emergency Disconnect System (EDS) 20

Recommend

More recommend