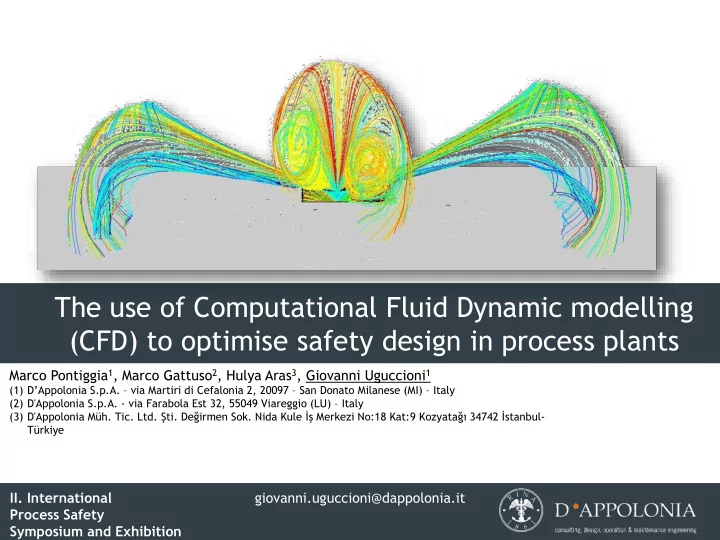

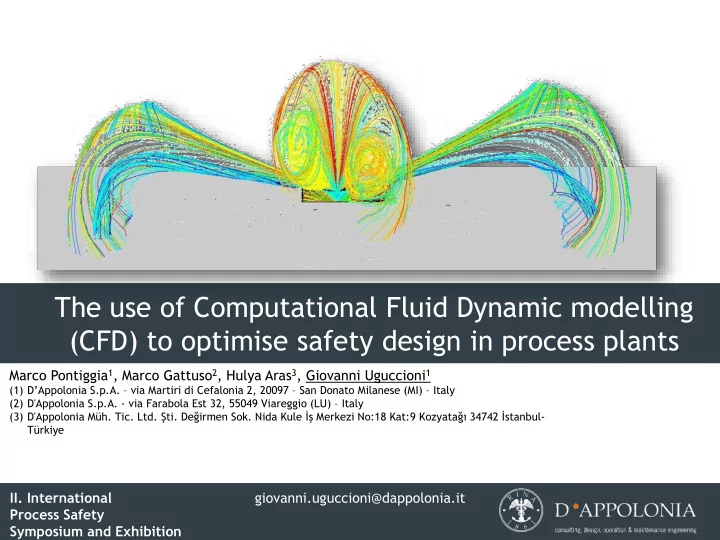

The use of Computational Fluid Dynamic modelling (CFD) to optimise safety design in process plants Marco Pontiggia 1 , Marco Gattuso 2 , Hulya Aras 3 , Giovanni Uguccioni 1 (1) D’Appolonia S.p.A. – via Martiri di Cefalonia 2, 20097 – San Donato Milanese (MI) – Italy (2) D'Appolonia S.p.A. - via Farabola Est 32, 55049 Viareggio (LU) – Italy (3) D'Appolonia Müh . Tic. Ltd. Şti . Değirmen Sok. Nida Kule İş Merkezi No:18 Kat:9 Kozyatağı 34742 İstanbul - Türkiye II. International giovanni.uguccioni@dappolonia.it Process Safety Symposium and Exhibition

Summary • Introduction • CFD approach description • Case #1 – Outdoor Toxic gas dispersion • Case #2 – Indoor Toxic gas dispersion Case #3 – Flammable gas dispersion, mitigation design • Conclusions • II. International giovanni.uguccioni@dappolonia.it Process Safety Symposium and Exhibition

D’Appolonia Saint Petersburg Rotterdam A Company belonging to the RINA Group of Italy providing Leuvren Beijing Bucharest Washington DC Seoul Istanbul engineering and consultancy services to Clients worldwide, Basra Cairo through a network of Project offices and Local companies, Abu dhabi Mumbai including Turkey (D’Appolonia Müh . Tic. Ltd in Istanbul) Maputo Durban Montevideo 2014 Project Countries

D’Appolonia Main Services in the Process sector Geosciences Environment & Permitting Health, Safety and Loss Prevention Simulation & Modeling Concept, Feasibility & Design Project Management Consulting Operation and Maintenance Asset Integrity Management (AIM+)

D’Appolonia Process Safety services L OSS P REVENTION – QRA - S AFETY C ASES - SIL - H AZARDOUS A REAS C LASSIFICATION - S AFETY C RITICAL E LEMENTS – F IRE P ROTECTION STUDIES – G AS & L IQUID D ISPERSION S IMULATION - 3D C ONSEQUENCE M ODELING – H UMAN F ACTOR A NALYSES HSE M ANAGEMENT - E MERGENCY P LANNING - A CCIDENT I NVESTIGATIONS - HAZOP - HAZID - R ELIABILITY STUDIES (RAM) - A VAILABILITY A NALYSES - B USINESS C ONTINUITY - O CCUPATIONAL H EALTH - T RAINING – A UDITS

CFD Tools Introduction 3D modelling, • • Full 3D meshing Equivalent • porosity • Wide application Integral models range General • Good accuracy even • Low resource The tool should be in geometrically consuming complex environment suitable for the widest • One dimensional range of applications • Large computational modeling time • Roughness height for geometry representation • Large overestimation of damage distances are possible Economic Accurate The tool should be low The tool should be able time and resources to describe the consuming phenomena II. International giovanni.uguccioni@dappolonia.it Process Safety Symposium and Exhibition

INTRODUCTION CFD approach Scenario Calculation • 3D model import • Boundary types • Post processing or construction tools and • Hazardous • Most effective characterization • Mesh design • Results material model selection interpretation • Model tuning • Source term • Convergence characterization criteria Geometry Boundaries Results Open Issues New methodology • • Lack of data Easy-accessible data Modified k- ε for • 3D format compatibility • Customizable level of Dose routine Probit atmospheric • Data corruption implementation detail turbulence • Level of detail • Fast geometry building II. International giovanni.uguccioni@dappolonia.it Process Safety Symposium and Exhibition

CASE #1 C HLORINE RELEASE (IDLH = 10 PPM ) O PERATIVE CONDITIONS : 3 BARG , 50 ° C H OLE SIZE : 60 MM II. International giovanni.uguccioni@dappolonia.it Process Safety Symposium and Exhibition

CASE #1 - Problem Simple analytical models for consequence assessment provide very high danger distance s (approx 7 km to IDLH value, 10 ppm and approx 700 m to the 2,5% fatality probability. Major and costly plant modifications could be required by Authorities in charge of approving the plant safety report if this danger distances were confirmed. A more detailed and realistic modeling was required to consider the effect on the gas dispersion of local terrain condition. II. International giovanni.uguccioni@dappolonia.it Process Safety Symposium and Exhibition

CASE #1 SET UP – Geometry and Release Earthwork (3m) C HLORINE RELEASE (IDLH = 10 PPM ) Wood (20m) O PERATIVE CONDITIONS : 3 BARG , 50 ° C H OLE SIZE : 60 MM Duration Velocity Mass flowrate Step [s] [m/s] [kg/s] Plant (5-15m) 1 180 286 3.3 2 30 276 2.8 Release point 3 45 244 1.9 4 45 129 0.7 5 10 95 0.5 II. International giovanni.uguccioni@dappolonia.it Process Safety Symposium and Exhibition

Case 1 GEOMETRY BUILDING OBSTACLES TERRAIN Shuttle Radar Topography Mission: 90 m Geo-referenced aerial photograph resolution cartesian elevation map II. International giovanni.uguccioni@dappolonia.it Process Safety Symposium and Exhibition

CASE #1 SET UP – Wind Direction • Wind speed 2 m/s, Pasquill class F ASsM for atmospheric North-West North • profiles tuning North-West: minimum • slope, open field • North: Increasing terrain elevation, largest obstacle downwind the release • South: Directed towards a a valley, obstacles upwind with respect to release South point II. International giovanni.uguccioni@dappolonia.it Process Safety Symposium and Exhibition

CASE #1 – Results Wind to NW Strong recirculation caused by plant structures Shifting in release point (chlorine release takes place from the building wake) Shifting in plume direction due to terrain slope II. International giovanni.uguccioni@dappolonia.it Process Safety Symposium and Exhibition

CASE #1 – Results Wind to N Strong recirculation caused by plant structures Wood weakly influences chlorine cloud at 10 ppm Wood strongly influences Probit values, since they involves higher chlorine concentrations Terrain slope influences chlorine plume direction II. International giovanni.uguccioni@dappolonia.it Process Safety Symposium and Exhibition

CASE #1 – Wind to N Detail II. International giovanni.uguccioni@dappolonia.it Process Safety Symposium and Exhibition

CASE #1 – Results Wind to S Strong recirculation caused by plant structures Upwind obstacles (wood and terrain slope) strongly enhance turbulence and recirculation The valley further increase chlorine mixing with fresh air thus reducing IDLH and Probit distances II. International giovanni.uguccioni@dappolonia.it Process Safety Symposium and Exhibition

CASE #1 – Results Wind Vulnerability Vulnerability Vulnerability IDLH direction 0.0035% 0.15% 2.5% Damage distances North-West 3480 721 472 309 North 2840 303 267 158 South 2110 289 186 103 Analytical 6615 1588 1023 646 Model Reduction in Wind Vulnerability distances damage IDLH direction (average) North-West 47% 52% North 57% 76% South 68% 82% II. International giovanni.uguccioni@dappolonia.it Process Safety Symposium and Exhibition

CASE #1 - Conclusions Authorities were satisfied that the reference accidental scenario was not able to reach the huge distances predicted by analytical models. Realistic emergency plans could be developed. Plant operation was granted. II. International giovanni.uguccioni@dappolonia.it Process Safety Symposium and Exhibition

CASE #2 - Problem PSVs of a series of reactors inside a building discharge a solution of Ammonia (NH3) inside a collection open drain outside the building. In case of a release, can ammonia recirculate inside the building, causing danger to the operators inside? Shall any design modification or specific operating procedure be developed to ensure safety or personnel, and if so which one? II. International giovanni.uguccioni@dappolonia.it Process Safety Symposium and Exhibition

CASE #2 – Description • Ammonia release following a PSV opening • Short transient (about 30 seconds) 3 1 • Three release points • Effects of geometry heavily influences release and dispersion • Target is to identify potential toxic risk for people working in the facility 2 • Toxic effect calculated with probit approach II. International giovanni.uguccioni@dappolonia.it Process Safety Symposium and Exhibition

CASE #2 – Geometry A B detail C D II. International giovanni.uguccioni@dappolonia.it Process Safety Symposium and Exhibition

CASE #2 – Screenshots Release Point 1 Release Point 3 II. International giovanni.uguccioni@dappolonia.it Process Safety Symposium and Exhibition

CASE #2 – Release point 3 II. International giovanni.uguccioni@dappolonia.it Process Safety Symposium and Exhibition

20 m CASE #2 – Screenshots Release Point 1 After 30 s After 45 s Level 20 m Level 24 m II. International giovanni.uguccioni@dappolonia.it Process Safety Symposium and Exhibition

CASE #2 – Relase point 3 II. International giovanni.uguccioni@dappolonia.it Process Safety Symposium and Exhibition

Recommend

More recommend