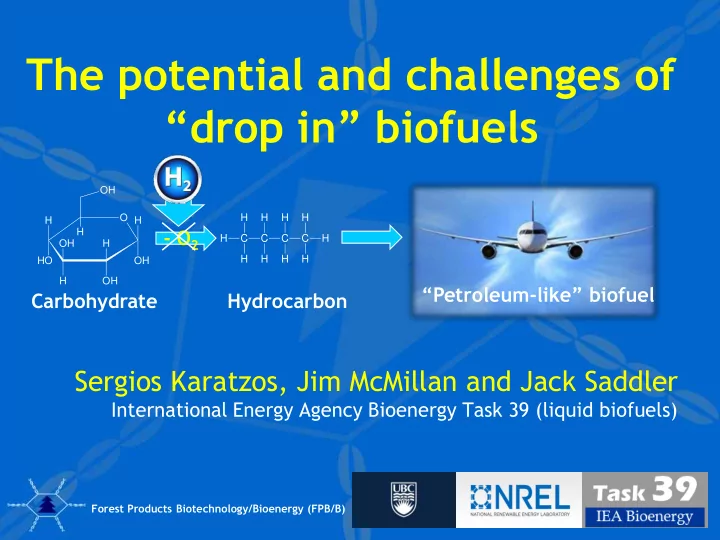

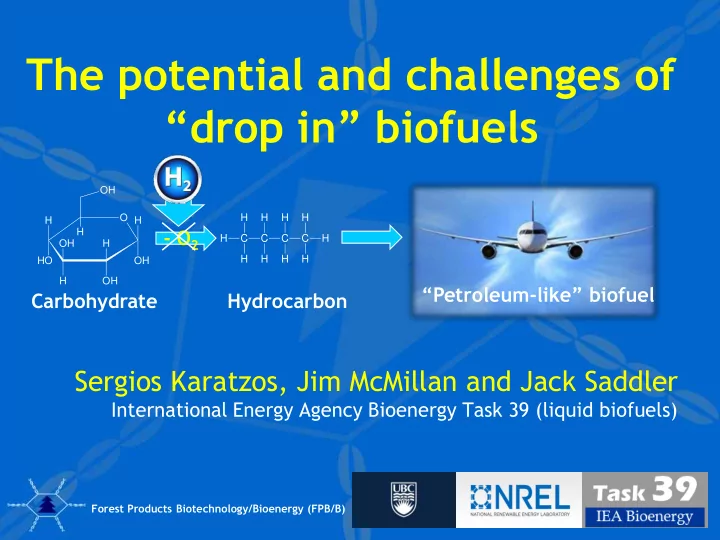

The potential and challenges of “drop in” biofuels OH O H H H H H H - O 2 H H C C C C H OH H H H H H H O OH H OH “Petroleum - like” biofuel Carbohydrate Hydrocarbon Sergios Karatzos, Jim McMillan and Jack Saddler International Energy Agency Bioenergy Task 39 (liquid biofuels) Forest Products Biotechnology/Bioenergy (FPB/B)

Commissioned Task 39 ‘drop in’ biofuel report OVERVIEW Definition Role of Hydrogen in drop in biofuels Role of Hydrogen in petroleum industry TECHNOLOGIES Forest Products Biotechnology/Bioenergy at UBC

Definition of a “drop - in” biofuel Bioethanol: Biogenic ethyl alcohol Biodiesel: Fatty acid methyl esters (FAME) Drop in Biofuels: Liquid bio-hydrocarbons that are functionally equivalent to petroleum fuels and as such compatible with existing petroleum infrastructure. Examples: Hydrotreated Vegetable Oils (HVO) Hydrotreated Pyrolysis Oils (HPO) Fischer Tropsch Liquids (FT liquids) Forest Products Biotechnology/Bioenergy at UBC 3

Oxygen Challenge Oxygen is present in biomass in the form of hydroxyls, esters, and ethers Can oxidize fuel components, reactors and pipeline metallurgy to cause corrosion Oxygen content reduces energy density CH 3 Ethanol Biodiesel (fatty acid methyl ester) Forest Products Biotechnology/Bioenergy at UBC 4

The Hydrogen-Oxygen dilemma “Drop - in biofuels” is a loose term referring to liquid biofuels containing low or no oxygen content Deoxygenation requires hydrogen inputs or “oxidizing/burning” of feedstock carbon High H/C eff ratio feedstocks such as lipids are well suited for drop-in biofuel production Forest Products Biotechnology/Bioenergy at UBC 5

What will determine the success of “drop in biofuels”? Drop-in biofuel technologies complexity and hydrogen demand Commercialization challenges such as capital, yield and refinery insertion Crude oil is becoming increasingly hydrogen deficient (‘heavier’ and ‘sourer’) Forest Products Biotechnology/Bioenergy at UBC 6

Crude oil quality declining… 90 80 Million barrels per day 70 60 50 Heavy Sour Light Sour 40 Light Sweet 30 20 “Sour” = High Sulfur 10 0 1990 2000 2010 2020 Purvin & Gertz forecast for world crude oil quality (Source: data from EIA) Forest Products Biotechnology/Bioenergy at UBC 7

Future competition for Hydrogen inputs… Heavy oil processing e.g. Venezuela and Alberta Ammonia industry Drop-in biofuels? Forest Products Biotechnology/Bioenergy at UBC 8

Hydrotreating and Hydrocracking Hydrotreating (Removes sulfur impurities as H 2 S) Hydrocracking (breaks heavy oil to lighter molecules) Heavy crude molecule Gasoline range molecule Diesel range molecule Forest Products Biotechnology/Bioenergy at UBC 9

US Hydrotreating capacity 1990-2030 30 25 million barrels per day 20 15 10 Rapid increase in H 2 consumption in US refineries 5 0 1990 1995 2000 2004 2010 2015 2020 2025 2030 10 Forest Products Biotechnology/Bioenergy at UBC Source EIA, Annual Energy Outlook 2006

Natural gas: Where H 2 comes from 90 % of commercial H 2 comes from steam reforming natural gas CO 2 CH 4 Steam reforming H 2 ENERGY INTENSIVE PROCESS!! Forest Products Biotechnology/Bioenergy at UBC 11

Role of H 2 in upgrading petroleum and drop-in biofuels Petroleum Drop-in Biofuels No Sulfur Increasing Sulfur content Increasing heavy oil High Oxygen content of needs cracking feedstock needs hydrogenation Both require Hydrogen for upgrading to finished fuels Hydrogen will likely come from Natural Gas Forest Products Biotechnology/Bioenergy at UBC 12

Commissioned Task 39 ‘drop in’ biofuel report OVERVIEW Definition Role of Hydrogen in drop in biofuels Role of Hydrogen in petroleum industry TECHNOLOGIES Forest Products Biotechnology/Bioenergy at UBC

The commercialization potential of Drop in Biofuel platforms and their H 2 dependence Oleochemical (HVO, algae) Thermochemical (Pyrolysis - HPO, Gasification FT-liquids) Biochemical (Advanced Fermentation) Hybrid platforms (e.g. Virent, Zeachem, Lanzatech) Forest Products Biotechnology/Bioenergy at UBC 14

Technology pathways to “drop - in” CONVENTIONAL INTERMEDIATES Higher alcohols Hydroprocessing Bio (e.g. Gevo) sugar crop Isoprenoids hydrolysis fermentation sugars (e.g. Amyris) Biomass fiber Sun photons, water, CO 2 Thermo catalytic FT liquids gasification syngas and nutrients conversion (e.g. CHOREN) HPO pyrolysis biooil upgrading (e.g. ENSYN) animal digestion Oleo Blending lipids oilseed crop Autotrophic LEGEND algae materials drop-in processes fuel Forest Products Biotechnology/Bioenergy at UBC 15

Commercial drop-in biofuel companies Neste Oil facility, Rotterdam All based on oleochemical Neste Oil: 630,000,000 gallons diesel from palm oil Dynamic Fuels: 75,000,000 gallons diesel from animal fat Forest Products Biotechnology/Bioenergy at UBC 16

Many examples of commercial biofuel flights Virtually all based on oleochemical US Navy: Sept 2011 Solazyme algae oil and palm oil Continental Airlines: Nov 2011 Solazyme algae oil Alaska Airlines: Jan 2012 tallow and algae Lufthansa: July 2011 Jatropha, Camelina Finnair: July 2011 Used Cooking Oils Many more Forest Products Biotechnology/Bioenergy at UBC 17

Thermochemical drop-in biofuel platforms INTER- CATALYTIC MEDIATES UPGRADING treatment 1 treatment 2 Gases Pyrolysis HPO 500°C Hydro Hydro oil Hydrocracking Gasoline No O 2 Biomass Jet Tropsch Gasification FT liquids 900°C Fischer Diesel Syngas some O 2 Forest Products Biotechnology/Bioenergy (FPB/B) 18

Example of pyrolysis drop in facility: KiOR 13,000,000 gallons per year in Mississippi (in operation) H 2 Forest Products Biotechnology/Bioenergy at UBC 19

Forest BtL Oy and Choren’s Carbo-V 34,000,000 gallons per year of Gasification FT liquids by 2016 (Finland) CO 2 H 2 H 2 Pretreat. Gasification FT Hydrocracking conditioning Sundrop biofuels 50 MGPY Forest Products Biotechnology/Bioenergy at UBC 20

Drop in biofuels leveraging on Oil refineries OLEOCHEMICAL OIL REFINERY Lipids Gases THERMOCHEMICAL treatment 1 treatment 2 Hydrocracking Gasoline Pyrolysis HPO Hydro Hydro oil Jet Biomass Diesel Tropsch Gasification FT liquids Fischer Syngas over the fence H 2 Forest Products Biotechnology/Bioenergy (FPB/B) 21

Challenges of hydrocracking biofeed: The Haldor Topsoe experience Higher Hydrogen consumption requirements more than doubled when just 5% of feed was replaced with biofeed! Presence of oxygenated gases such as CO and H 2 O Heterogeneity of feedstock (Catalyst design challenges) Source: Haldor Topsoe, 2009 22 Forest Products Biotechnology/Bioenergy at UBC

Major upscaling challenges for each platform Pyrolysis Hydrogen Hydrotreating catalyst Gasification Capital / scale Feedstock /yields HVO oleochemical Feedstock Sources: Jones et al. 2009; Swanson Refinery insertion challenges et al. 2010; Pearlson et al. 2011 Forest Products Biotechnology/Bioenergy at UBC 23

Biochemical: Sugar fermentation to drop-in FERMENTATION Target molecule SUGAR Modified algae, Long alcohols bacteria or yeast Aliphatic chains Major advantages Pure and “functionalized” product streams suitable for value added markets Major challenges Volumetric productivity about 10x lower than ethanol Recovery challenges: e.g. recovery from fermentation broth and intracellular expression Sugar feedstock highly oxidized (H/C = 0) Forest Products Biotechnology/Bioenergy at UBC 24

Summary Oleochemical: commercial now and less H 2 -dependent with considerable potential for growth (feedstock challenges?) Thermochemical well suited for long term drop-in biofuels H 2 and catalyst challenges (Pyrolysis), Scale challenges (Gasification) Leveraging on oil refineries: more challenging than expected Biochemical “drop - in” products more valuable in rapidly growing chemicals markets Accessing cheap/renewable Hydrogen will be a key challenge for both drop-in biofuels and crude oil of decreasing quality Forest Products Biotechnology/Bioenergy at UBC 25

ACKNOWLEDGEMENTS International Energy Agency Bioenergy Task 39 colleagues www.Task39.org Forest Products Biotechnology/Bioenergy (FPB/B)

Recommend

More recommend