The Game Changer in Medical Wast e Management Sterilwave is the most innovative ‘on-site’ medical waste treatment service seen by the NHS in two decades. Our modern waste process intelligently grinds then microwaves the waste into a sterile RDF/SRF “flock” that is completely safe to handle and can be disposed of as domestic waste or used as a high calorific fuel source in Waste to Energy plants. Highlights First Sterilwave P lant launched at Whipps Cross • Hospital in December 2016 Full Environment Agency approval of the • Sterilwave process achieved. No one else with a similar technology has an EA Permit or is likely to have one in the next 3 years Improved sustainability, better c ompliance and • fixed pricing “Sterilwave is the most innovative on-site medical waste service that the NHS has seen in over 20 years” Terry Hewitt, MD Background Recently, the NHS and Medical Waste Service providers have focused a lot of their energies on improving the segregation of their Hospital's waste. Recent legislation has also enabled them to categorise a large percentage of High Temperature Incineration Waste (“HTIW”) as lower cost Alternative Treatment ( AT ) waste and many Hospitals have also started to roll out their Offensive Waste ( OW ) streams.

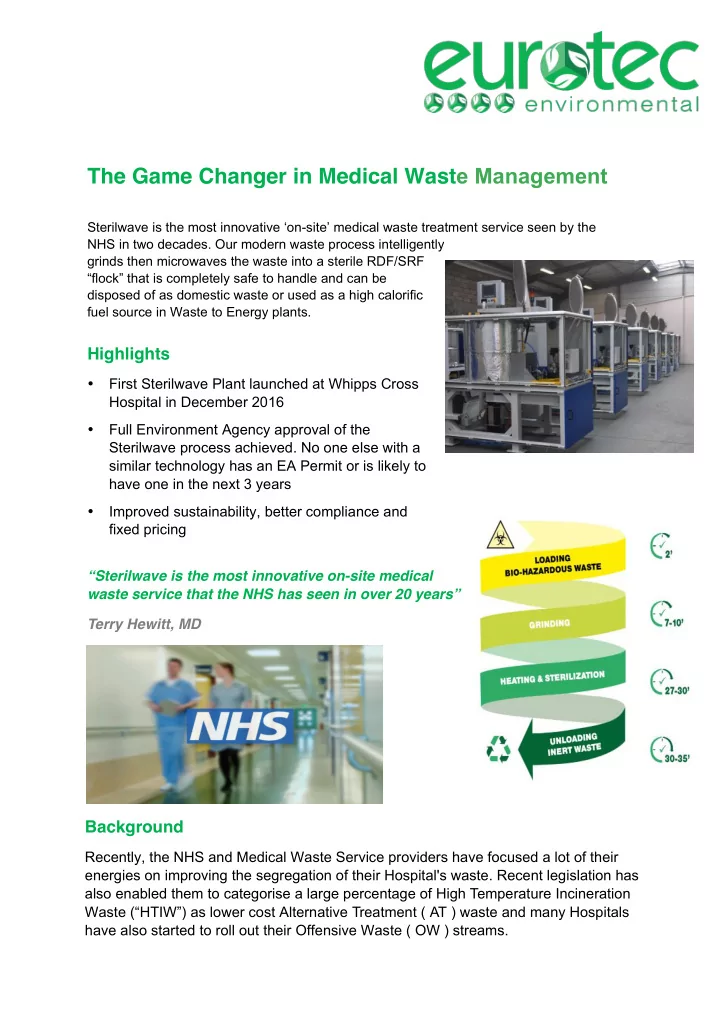

Although these new waste streams have brought benefits, both NHS Trusts and Waste FM providers have been looking at a variety of methods and technologies to best utilise these streams in order to maximise the savings available , whilst also becoming more compliant and improving sustainability. Until now, a viable solution has been difficult to find. Introducing Eurotec Sterilwave – the Game Changer in Clinical Waste Management Eurotec Environmental has developed the most innovative on-site clinical waste treatment that the NHS has seen in over two decades. Our modern waste processing is carried out in the innovative Bertin Sterilwave unit. This smart technology cleverly grinds and then microwaves the waste in just one single short cycle turning Offensive and Alternative Category clinical waste into an unrecognisable, sterile flock that can be safely disposed of as domestic waste or used as a calorific fuel in Waste to Energy plants. We br oke ground on the first UK Sterilwave Plant at Barts Health Hospital, Whipps Cross, London in July 2016 and went fully operational in January 2017 . Barts are hugely supportive of our Sterilwave process and now Whipps Cross is fully operational they plan to have Plants installed in at least 2 other Barts Health NHS sites. The Environment Agency have also been very supportive and have fully approved our process. The EA have issued Eurotec Environmental with the Permit to operate our Sterilwave process in the UK&ROI and no other similar technology has an EA Permit or is likely to achieve one in the next 3 years . The Sterilwave Process Eurotec's Sterilwave process reduces the cost to the NHS of the disposal of hazardous waste streams whilst providing peace of mind by providing Fixed Price contracts* normally for 5 or 7 years ( * subject to RPI ). Although pricing is clearly an important consideration, our Eurotec Sterilwave process is not just about being competitive on cost; we also bring other significant environmental benefits such as : 1. An 80% reduction in transport to site for the OW and AT waste streams. 2. The complete removal of the need for Consignment Notes and the associated costs and administration activities. 3. A total removal of off-site compliance issues caused by poor segregation. As the AT and OW waste streams will never leave the site until they are fully treated, any poor segregation issues are handled on-site and corrected immediately. ( list of benefits continues over )

4. A significantly improved Carbon Footprint by up to 30% due to the much reduced transport movements. 5. The ability to create a Profit Share by using the Sterilwave Plant to treat Third Party Clinical Waste (also providing positive PR) 6. The opportunity to save even more money by implementing our behavior Change in Waste service that has enabled other Acute Hospital's to make significant savings by enabling them to fully roll-out their Offensive Waste Stream, improve staff waste knowledge and the hospital waste processes plus also saving energy. During our treatment process, clients waste is reduced in volume and weight by up to 80% and 20% respectively which enables Eurotec to remove the SDF/RDF in 15-20 tonne loads, as opposed to the existing highly inefficient 1.3 tonne loads in multiple 770 litre containers. Our Sterilwave process presents no risk of infection and is environmentally friendly, producing zero emissions. The Technology The Sterilwave machine is the principle equipment to be utilised for the safe processing and sterilisation of AT and OW waste. The process is safe, effective, certified and straightforward. The following equipment will also be provided to support our on-site service: • Clinical Waste Bins - both 770 litre and 360 litre • Bin Washing Plant • Weighing and Tracking System • Processed Waste Storage Unit • Disposal of treated RDF - if required Full detailed specifications for the machine and it ' s operation can be found at www.sterilwave.com. In essence, though, the waste is mechanically pulverised by rotary blades and is subjected to microwaves to provide certainty of sterilisation to both EU and UK standards. A sterilisation cycle takes a maximum of 32 minutes. The supplier of the machinery, Bertin, has been specifically selected by Eurotec Environmental for the following reasons: • The m achinery is already approved and being used throughout the world • Bertin is a substantial entity and provides full back up of spares, training and support • Certainty of processing

The End Product The end product of the Sterilwave process is a sterile "flock". This waste flock is unrecognisable as medical origin waste and can be designated as a Recycled Derived Fuel (RDF) or Solid/Specified Recovered Fuel (SRF) with a Calorific Value (CV) of approx. 14MJ/KG. Our intention is to ensure that our flock is used to feed energy from waste plants (such as cementation plants and specially adapted and licensed R1 plants) in the UK. It is, however, worth noting that this waste, once processed, could legally be taken to any landfill or municipal incinerator. AT waste is now often being burned in Clinical Waste incinerators to act as a fuel to replace the lost HTIW. Many NHS clients have raised the question as to why they are now being charged two prices for the same disposal service when both are transported and incinerated in exactly the same way. It is also well known in the waste industry that the removal from site of OW and AT waste in 770 litre bins is highly inefficient, allowing the transfer off-site of just 1.2 tonnes of waste for every 30 bins loaded on an HGV. Eurotec Environmental is significantly different in our approach to the provision of AT/OW treatment services. We treat the waste on the producer site into a sterile, odourless, safe flock that is then moved off-site in 20 tonne loads in compactor units as NON HAZ waste. This makes our service extremely efficient with no compliance issues and a significant "tick" in the environmental box in terms of Carbon Reduction and vehicle movements. Environment Agency Permitting Eurotec Environmental has permit approval with the Environment Agency (EA) for the Barts Health NHS Trust at their Whipps Cross Hospital site. The EA does not issue "blanket" permits, licenses or nationwide accreditation for any individual waste treatment process no matter how many have been successfully installed in the UK. As such, each and every time we want to implement one of our Clinical Waste (CW) treatment facilities on a site then it must be individually approved by the EA as if it was the first installation. This provides our clients with significant peace of mind as this means that we cannot operate at a site until the EA have inspected and approved our site, our technology and our processes and have fully signed off. Each specific process machinery will be tested in terms of mechanical, electrical and sterilisation/incineration/autoclaving criteria in terms of biological testing by an independent laboratory advised by the EA for that specific site. All of the associated systems that make up the proposed ‘O perating Site ’ including waste reception and storage area, HSE/EMS, emissions to atmosphere and transport movement are also confirmed adequate at this time of commissioning and testing. Only then will any issued Permit become valid. As a French manufactured technology the Sterilwave unit has, of course, already passed all of it ' s independent sterilisation testing in Paris under the control of the French Institute de Paris. This is an EU and UK recognised certification and this testing will be duplicated on each and every site where we and our NHS and Waste FM clients wish to place a new Sterilwave process as part of obtaining a Permit. In the EU (although not in the UK) such certification is accepted as approval to install ( continues over )

Recommend

More recommend