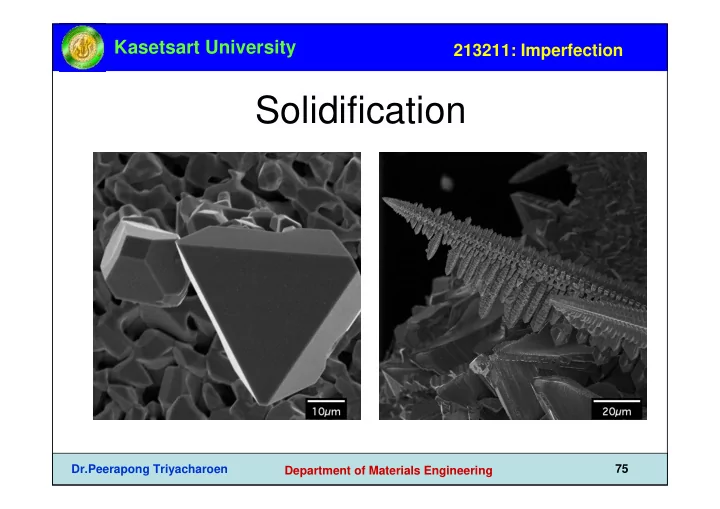

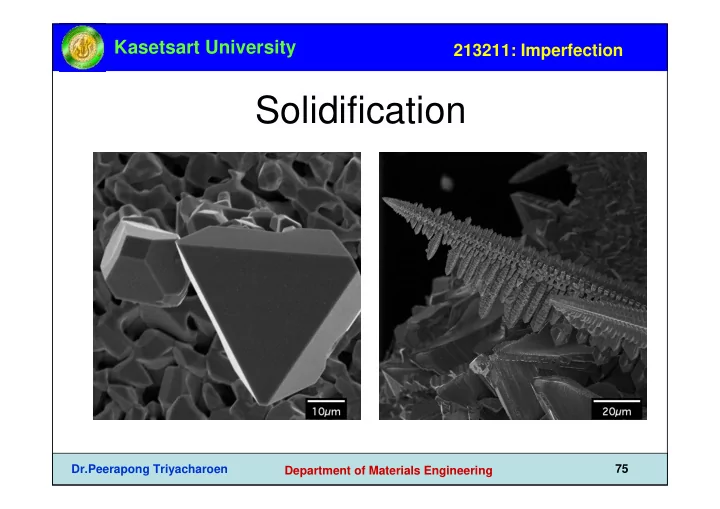

Kasetsart University 213211: Imperfection Solidification Dr.Peerapong Triyacharoen 75 Department of Materials Engineering

Kasetsart University 213211: Imperfection Schematic Solidification Stages Formation of Nuclei Growth of nuclei into crystals Completely solidified Nucleation Growth Dr.Peerapong Triyacharoen 76 Department of Materials Engineering

Kasetsart University 213211: Imperfection Nucleation 4 ∆ = π 3 ∆ + π 2 γ G r G 4 r T v 3 Nucleus r = radius of embryo or nucleus ∆ G v = volume free energy Embryo γ = specific surface free energy 4 = π r ∆ 3 G v 3 Dr.Peerapong Triyacharoen 77 Department of Materials Engineering

Kasetsart University 213211: Imperfection Homogeneous Nucleation • Occurs when the undercooling ( ∆ T) becomes large enough to cause formation of a stable nucleus. γ γ 2 2 T * = − = − m r ∆ ∆ ∆ G H T v f r* = critical radius T m = melting temperature ∆ T = undercooling (T m – T) ∆ H f = latent heat of fusion represents the heat given up during the liquid-to-solid transformation Dr.Peerapong Triyacharoen 78 Department of Materials Engineering

Kasetsart University 213211: Imperfection Heterogeneous Nucleation • Occurs in a liquid on the surfaces of its container, insoluble impurities, or other structural material which lower the critical free energy required to form a stable nucleus. Dr.Peerapong Triyacharoen 79 Department of Materials Engineering

Kasetsart University 213211: Imperfection Glasses • Amorphous (glassy) solid • Insufficient time for nuclei to form and grow by rapid cooling (rapid solidification processing) C r y s t a l l i n e S o l i d G l a s s Density Liquid Undercooled liquid T g T m Temperature Dr.Peerapong Triyacharoen 80 Department of Materials Engineering

Kasetsart University 213211: Imperfection Growth Mechanisms Need to remove two types of heat: 1. Specific heat: required to change temperature of a unit weight of the material by one degree. 2. Latent heat of fusion Planar Growth Dendritic Growth Dr.Peerapong Triyacharoen 81 Department of Materials Engineering

Kasetsart University 213211: Imperfection Casting or Ingot Structure Dr.Peerapong Triyacharoen 82 Department of Materials Engineering

Kasetsart University 213211: Imperfection Solidification Time Time required to completely solidify for a simple casting (t s ) : n ⎛ ⎞ V = ⎜ ⎟ t B Chvorinov’s rule s ⎝ ⎠ A B = mold constant, depending on the properties and initial temperature of both the metal and the mold V = volume of the casting A = surface area of the casting in contact with the mold n = constant (usually about 2) Dr.Peerapong Triyacharoen 83 Department of Materials Engineering

Kasetsart University 213211: Imperfection Effect on Structure and Properties SDAS = m kt Secondary Dendrite Arm Spacing: s k and m = constants depending on the metal composition Aluminum alloy Dr.Peerapong Triyacharoen 84 Department of Materials Engineering

Kasetsart University 213211: Imperfection Effect on Structure and Properties (con.) Aluminum casting alloy Dr.Peerapong Triyacharoen 85 Department of Materials Engineering

Kasetsart University 213211: Imperfection Example: Design of an Aluminum Casting Design the thickness of an aluminum casting whose length is 12 in. and width is 8 in., in order to produce a tensile strength of 40,000 psi. The mold constant in Chvorinov’s rule for aluminum alloys cast in a sand mold is 45 min/in 2 . Solution • Required SDAS = 0.007 cm to obtain a T.S. = 42,000 psi • Required solidification time = 300 s or 5 min n ⎛ ⎞ V B = 45 min/in 2 V = (8)(12)(x) = 96x = ⎜ ⎟ t B s ⎝ ⎠ A A = (2)(8)(12) + (2)(x)(8) + (2)(x)(12) = 40x + 192 2 ⎛ ⎞ ⎛ ⎞ 96 x ⇒ 96 x ⇒ x = 0.77 in. = 2 = = ⎜ ⎟ ⎜ ⎟ 5 min ( 45 min/ in ) ( 5 / 45 ) 0 . 333 + + ⎝ ⎠ ⎝ ⎠ 40 x 192 40 x 192 Dr.Peerapong Triyacharoen 86 Department of Materials Engineering

Recommend

More recommend