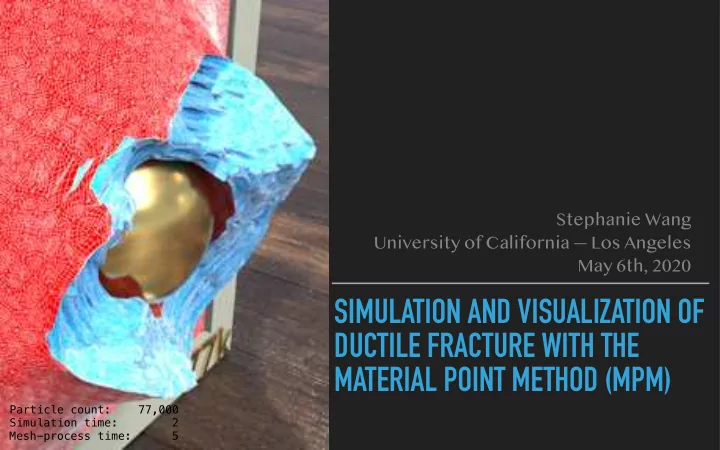

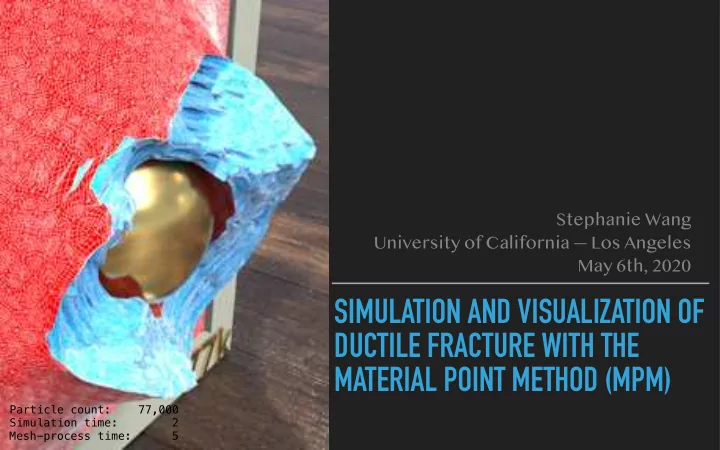

Stephanie Wang University of California — Los Angeles May 6th, 2020 SIMULATION AND VISUALIZATION OF DUCTILE FRACTURE WITH THE MATERIAL POINT METHOD (MPM) Particle count: 77,000 Simulation time: 2 Mesh-process time: 5

COLLABORATORS ▸ PhD Advisor: Joseph Teran, UCLA ▸ Xuchen Han, UCLA ▸ Qi Guo, UCLA ▸ Mengyuan Ding, UCLA ▸ Steven Gagniere, UCLA ▸ Leyi Zhu, University of Science and Technology of China ▸ Theodore Gast, JIXIE EFFECTS (UCLA) ▸ Chenfanfu Jiang, University of Pennsylvania (UCLA)

Particle count: 60,000 Simulation time: 11 Mesh-process time: —-

Particle count: 60,000 Simulation time: 11 Mesh-process time: 5

Particle count: 207,000 Simulation time: 16 Mesh-process time: 13

Particle count: 207,000 Simulation time: 16 Mesh-process time: 13

Particle count: 207,000 Simulation time: 16 Mesh-process time: 13

OUTLINE ▸ Material Point Method (MPM) ▸ Grid-particle transfer ▸ Force computation ▸ Simulation and visualization of ductile fracture ▸ Yield surfaces ▸ Mesh-processing ▸ Discussion

THE MATERIAL POINT METHOD Particle count: 200,000 Simulation time: 35 Mesh-process time: 16

MATERIAL POINT METHOD (MPM) ROUGH ALGORITHM ▸ Particles for state ▸ Grid for computations ▸ Interpolation between particles and grid ▸ Similar to FEM: Vertices for state, Mesh for computations

MATERIAL POINT METHOD (MPM) ROUGH ALGORITHM m n i = TransferP2G ( m p ) notation meaning when where v n i = TransferP2G ( v n p ) after x n +1 f n position particle i = ComputeForce () p forces i + ∆ t v n +1 before = v n f n ˜ v n velocity grid i i m n i forces i v n +1 v n +1 = TransferG2P (˜ ) never p i mass particle m p changes x n +1 = x n p + ∆ t v n +1 ⇐ Beware! p p

MATERIAL POINT METHOD (MPM) ROUGH ALGORITHM m n i = TransferP2G ( m p ) notation meaning when where v n i = TransferP2G ( v n p ) after x n +1 f n position particle i = ComputeForce () p forces i + ∆ t v n +1 before = v n f n ˜ v n velocity grid i i m n i forces i v n +1 v n +1 = TransferG2P (˜ ) never p i mass particle m p changes x n +1 = x n p + ∆ t v n +1 ⇐ Beware! p p

PARTICLE-GRID TRANSFER INTERPOLATION SCHEME ▸ Compactly supported kernel function ▸ Spline: C1 (C2) piecewise-polynomial ˆ N ( x ) Cubic Quadratic

PARTICLE-GRID TRANSFER INTERPOLATION SCHEME N ( x ) = ˆ N ( x ) ˆ N ( y ) ˆ ▸ Tensor product: N ( z ) ▸ Compute weights: w n ip = N ( x n i � x n p ) r w n ip = r N ( x n i � x n p ) ▸ Partition of unity X w n ip = 1 i ▸ Barycentric embedding X w n ip x n i = x n p i ▸ Conservation of momenta, non-increasing energy

PARTICLE-GRID TRANSFER INTERPOLATION SCHEME TransferP2G X m n w n i = Mass ip m p p Kernel at node X m n i v n w n ip m p v n i = Momentum p p TransferG2P X v n +1 v n +1 w n = ip ˜ p i i Kernel at particle

PARTICLE-GRID TRANSFER PIC, FLIP, APIC, RPIC, …… X m n w n i = ip m p p X m n w n i = ip m p X D n w n ip ( x n i − x n p )( x n i − x n p ) T p = p i 1 1 X v n w n ip m p v n X i = v n w n ip m p ( v n p + B n p ( D n p ) − 1 ( x n i − x n i = p )) p m n m n i i p p f n i = ComputeForce () f n i = ComputeForce () i + ∆ t i + ∆ t v n +1 = v n f n ˜ v n +1 = v n f n ˜ i i m n i i m n i i X v n +1 w n v n +1 ip ˜ = X p i v n +1 w n v n +1 ip ˜ = p i i i X B n +1 w n ip v n i ( x n i − x n p ) T = p x n +1 = x n p + ∆ t v n +1 i p p x n +1 = x n p + ∆ t v n p p Particle In Cell (PIC) Affine Particle In Cell (APIC)

PARTICLE-GRID TRANSFER PIC, FLIP, APIC, RPIC, …… ▸ Particle In Cell (PIC): Harlow 1964 ▸ Fluid Implicit Particle (FLIP): Brackbill and Ruppel 1986 ▸ Affine Particle In Cell (APIC): Jiang et al. 2015 ▸ Rigid Particle In Cell (RPIC): Jiang et al. 2015 ▸ Polynomial Particle In Cell (PolyPIC): Fu et al. 2017 ▸ Extended Particle In Cell (XPIC): Hammerquist et al. 2017

MATERIAL POINT METHOD (MPM) ROUGH ALGORITHM m n i = TransferP2G ( m p ) notation meaning when where v n i = TransferP2G ( v n p ) before x n +1 f n velocity grid i = ComputeForce () p forces i + ∆ t v n +1 after = v n f n ˜ v n position particle i i m n i forces i v n +1 v n +1 = TransferG2P (˜ ) never p i mass particle m p changes x n +1 = x n p + ∆ t v n +1 ⇐ Beware! p p

MATERIAL POINT METHOD (MPM) ROUGH ALGORITHM m n i = TransferP2G ( m p ) notation meaning when where v n i = TransferP2G ( v n p ) before x n +1 f n velocity grid i = ComputeForce () p forces i + ∆ t v n +1 after = v n f n ˜ v n position particle i i m n i forces i v n +1 v n +1 = TransferG2P (˜ ) never p i mass particle m p changes x n +1 = x n p + ∆ t v n +1 ⇐ Beware! p p

FORCE COMPUTATION DEFORMATION GRADIENT X b x b F x = Φ ( X , t ) F ( X , t ) = ∂ Φ ∂ X ( X , t ) x a X a Ω 0 Ω t

FORCE COMPUTATION DEFORMATION GRADIENT mesh-based forces: particle-based forces: F per triangle F per particle X X V 0 V 0 Φ = p Ψ ( F p ) Φ = e Ψ ( F e ) p e

FORCE COMPUTATION FORCE AS ENERGY GRADIENT P ( F ) = ∂ Ψ ▸ First Piola-Kirchoff stress ∂ F ( F ) ▸ Total potential energy X V 0 Φ = p Ψ ( F p ) p ! ▸ ``F is a function of x” X X F n x n q r N q ( X e ) T F n +1 v i ( r ω n ip ) T F n e = = I + ∆ t p p i q f i = − ∂ Φ ▸ Energy is a function of x ∂ x i ▸ Force can be computed from x ✓ ∂ Ψ ◆ f i = � ∂ Φ p ) T r ω n X V 0 ( F n = � ∂ F ( F p ( x )) p ip ∂ x i p

FORCE COMPUTATION HYPER-ELASTIC MODELS ▸ St. Venant Kirchhoff potential with Hencky strain F = U Σ V T ψ ( F ) = µ tr((ln Σ ) 2 ) + λ 2 (tr(ln Σ )) 2 ∂ψ ∂ F = U (2 µ Σ − 1 ln Σ + λ tr(ln Σ ) Σ − 1 ) V T ▸ (Easy for analytical plastic projection)

FORCE COMPUTATION FINITE ELEMENT ELEMENT

FORCE COMPUTATION FINITE ELEMENT ELEMENT

FORCE COMPUTATION FINITE ELEMENT ELEMENT

FORCE COMPUTATION FINITE ELEMENT ELEMENT X V 0 Φ = e Ψ ( F e ) e X F n x n q r N q ( X e ) T e = q ! − 1 X ! X X V 0 Φ = e Ψ ( F e ) F n x n q r N q ( ξ e ) T X q r N q ( ξ e ) T e = e q q

FORCE COMPUTATION PARTICLE MPM

FORCE COMPUTATION PARTICLE MPM

FORCE COMPUTATION PARTICLE MPM

FORCE COMPUTATION PARTICLE MPM

FORCE COMPUTATION PARTICLE MPM

FORCE COMPUTATION PARTICLE MPM

FORCE COMPUTATION PARTICLE MPM

FORCE COMPUTATION PARTICLE MPM X V 0 Φ = p Ψ ( F p ) p ! X F n +1 v i ( r ω n ip ) T F n = I + ∆ t p p i

FORCE COMPUTATION LAGRANGIAN MPM X V 0 Φ = e Ψ ( F e ) e X F n x n q r N q ( X e ) T e = q X f n ω n iq f n i = q q

SIMULATION AND VISUALIZATION OF DUCTILE FRACTURE Particle count: 4,000 Simulation time: 5 Mesh-process time: 0.2

YIELD SURFACES RANKINE YIELD SURFACE [MÜLLER ET AL. 2014] ▸ Constraining maximal principal stress k u k = k v k =1 u T τ v − τ C ≤ 0 y ( τ ) = max ▸ Mode I yielding (tension) ▸ Softening rule ✓ ◆ ⌧ n +1 = ⌧ n k u k = k v k =1 u T ✏ n +1 v − u T ✏ tr ˜ C + ↵ max max v k =1 ˜ v C k ˜ u k = k ˜

Particle count: 130,000 Simulation time: 15 Mesh-process time: 8

YIELD SURFACES VON MISES (J2) YIELD SURFACE ▸ Constraining shear stress y ( τ ) = k τ � tr( τ ) I k F � τ C 0 ▸ Mode II and III yielding (shear) ▸ Softening can be added

τ C /E = 1 τ C /E = 0 . 7 τ C /E = 0 . 5 Particle count: 60,000 Simulation time: 11 Mesh-process time: 4

Particle count: 60,000 Simulation time: 11 Mesh-process time: 5

MESH-PROCESSING THREE STEPS OF CREATING FRACTURING MESH ▸ Fracturing topology (that evolves with time) ▸ Extrapolate positions for the added vertices ▸ Smoothing crack surface to reduce mesh-dependent noise ▸ Advantage: per-frame post-process instead of per-time-step treatment

MESH-PROCESSING FRACTURING TOPOLOGY

MESH-PROCESSING FRACTURING TOPOLOGY

MESH-PROCESSING FRACTURING TOPOLOGY

MESH-PROCESSING FRACTURING TOPOLOGY

MESH-PROCESSING FRACTURING TOPOLOGY

MESH-PROCESSING FRACTURING TOPOLOGY duplicated vertices

MESH-PROCESSING FRACTURING TOPOLOGY

MESH-PROCESSING FRACTURING TOPOLOGY

MESH-PROCESSING FRACTURING TOPOLOGY ▸ Subdivided mesh ▸ Edge-stretching cutting criterion 1 2 3 ▸ Evolves with time 3 4 5 6

MESH-PROCESSING EXTRAPOLATING POSITIONS FOR ADDED VERTICES

MESH-PROCESSING EXTRAPOLATING POSITIONS FOR ADDED VERTICES

MESH-PROCESSING EXTRAPOLATING POSITIONS FOR ADDED VERTICES

MESH-PROCESSING EXTRAPOLATING POSITIONS FOR ADDED VERTICES

MESH-PROCESSING EXTRAPOLATING POSITIONS FOR ADDED VERTICES

MESH-PROCESSING EXTRAPOLATING POSITIONS FOR ADDED VERTICES

MESH-PROCESSING EXTRAPOLATING POSITIONS FOR ADDED VERTICES

Recommend

More recommend