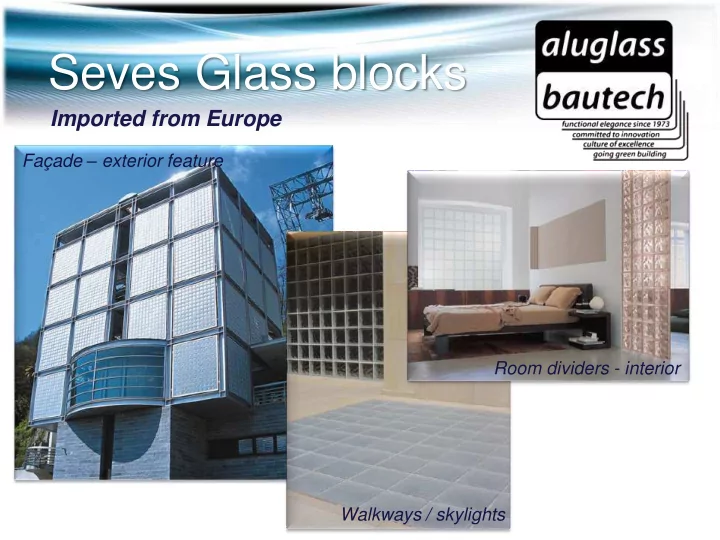

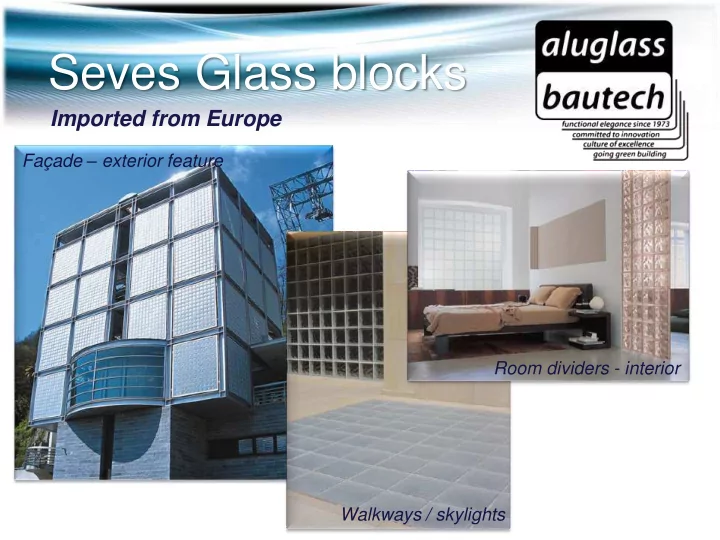

Seves Glass blocks Imported from Europe Façade – exterior feature Room dividers - interior Walkways / skylights

Index Introduction The GREEN glass block Technical information Installation methods Traditional installation with cement mortar Quicktech system Vetroquick system Notes regarding installation Expansion joints Galvanised steel rods Calculating the number of glass blocks and spaces Glass block range

Introduction Energy saving: The building of a ‘ greener ’ tomorrow starts today with the choice of smart materials. Resistance: Protect all the buildings from fire with fireproof glass bricks. Safety: For all those applications which need a high safety level. Insulation: Create a more comfortable and functional environment with glass bricks insulation properties.

Introduction Privacy: Even where there is a need for privacy, there is a need for natural light. Design: A definition of space with a harmonic combination of colours, light, shapes and textures. Tailor made: The most prestigious projects realised in glass bricks.

The glass block Pegasus glass blocks reduce the thermal transmittance of the classic glass block up to 50% • creating architectural façades made entirely of glass blocks that promote the conservation of energy and safeguards the environment • introduction of a low-emissivity glass plate and pressure controlled argon gas • can reach a thermal transmittance value of U=1.5 W/m² K . • CE certification in accordance with norm UNI EN 1051-2: – Resistance to compression along the side of the block according to the EN 1051/1 2005 standards; – Resistance to thermal shock according to the EN 1051/2 2008 standards; – Evaluation of the solar characteristics, according to the EN 410 2000 standards; – Calculation of the U-value according to the EN 673 2005 standards; – Sound insulation according to the EN 7117/1 2007 standards.

Technical information thermal insulation - the “thermal bridges” created by gaps between glass bricks are reduced compressive strength - only excellent quality raw materials and a manufacturing process that dedicates special attention to sealing and annealing can guarantee high compressive strength in glass blocks thermal endurance - thermal shock is one of the most stringent tests that glass bricks must undergo to verify their strength and resistance light transmission - transparency, one of the most important features of glass bricks, creates different effects in relation to the many possible combinations that can be made using different patterns, shapes, finishes and colours sound insulation - features such as mass and the internal air space guarantee that glass bricks offer a high level of sound insulation, even superior to that of brick walls of identical thickness fire resistance and reaction - glass, by its nature, tends to break quickly when subjected to thermal shock, glass brick structures offer a good level of safety - they constitute an effective fire barrier internal pressure - the pressure inside glass bricks is lower than the atmospheric pressure - in the event of breakage, the glass fragments tend to converge towards the inside (implosion) of the glass blocks instead of being projected outwards (explosion)

Installation methods Traditional installation with cement mortar Place a slip joint into Arrange the vertical the horizontal strips Use a trowel long guides, they must be to prevent enough to allow you to plumb, and 100/120 expansion/friction work easily between the cm apart to assure between the base of vertical reinforcement that the wall itself will the panel and the bars. Apply cement be perfectly plumb. supporting surface. mortar between the The wall must be Place the base strips. perfectly vertical both expansion/settling Position the first row of lengthwise and joints on the side Seves glass blocks. upwards in order to and at the panel avoid eccentric loads support points Build the first course Place the reinforcing perfectly plumb. Use the rod on the central wing To guarantee plastic spacers to make of the spacer to stability for large even joints. Apply mortar prevent it to touch the walls it is better to to the vertical spaces glass block side. Insert use U-sections, between the glass blocks the reinforcement which are plugged or you have just laid, bars, vertically and cramped to the temporarily remove the horizontally; the bars adjacent supporting spacers as you work and should not be more structures then replace them than 50 cm apart. Finish the joints only Apply the finishing, fill the joints when the mortar is well; use soft brushes and completely hardened. plastering trowels. Make a Remove the outer perimeter cordon, or part of the plates of the spacer outside joint, using elastic sealant using a tool that will to prevent cracking along the not scratch the glass expansion/settling joints.

Installation methods Quicktech system

Installation methods Vetroquick system

Notes regarding installation Expansion joints The expansion joint is necessary for correctly installing glass blocks and it must be placed on lateral (sides) and upper edge in order to prevent possible settling of new structures from transmitting vibrations and damaging the glass blocks.

Galvanised steel rods • The wall must be reinforced in vertical and horizontal joints to guarantee higher stability and safety. • Rods shall not be welded, because this would create a too ridged structure and damage the glass part.

Calculating the number of glass blocks and spaces Dimension Ave unit Approx weight of structure Number of pieces per sq.m (cm) weight (kg) (kg/sq.m) 2mm 5mm 10mm 16m 2mm 5mm 10mm 16mm joint joint joints m joint joint joints joints (Pegasu (Pegasu joints (Pegas (Pegas s) s) us) us) ≈78 ≈80 ≈78 ≈82 ≈27 ≈26 ≈23 19x19x8 2.3 25 ≈92 ≈94 ≈92 ≈96 ≈54 ≈51 ≈46 19x9.4x8 1.3 50 ≈81 ≈84 ≈16 24x24x8 4.1 16 D = No. of spacers D = (n+1) x (m+1) n = No. o f horizontal glass elements M = No. of vertical glass elements

Glass block range Please view our website for the extensive range 198 Wave 198 Clearview Size: 19x19x8cm Weight: 2.3 Kg 198 Savona Joint width: 10mm or 16mm 1908 ½ Wave No. Pieces/ m2: 25 Sound Insulation: 40dB Thermal insulation: 2.81 W/m2 °K Fire Resistance: integrity until 60 minutes and insulation until 15 minutes*

Glass block range 248 Wave 248 Clearview Size: 24x24x8cm Please view our website for Joint width: 10mm or 16mm the extensive range No. Pieces/ m2: 16 Sound Insulation: 40dB Thermal insulation: 2.81 W/m2 °K Fire Resistance: integrity until 60 minutes and insulation until 15 minutes*

Glass block range Patented by Seves, ENERGY SAVING effectively reduces the thermal transmittance of the glass block up to 50%, with the introduction of a low-emissivity glass plate and pressure controlled argon gas . The glass plate is inserted between the glass block halves to interrupt the thermal bridge, while the argon gas is added to reduce the thermal transmission caused by convective motion. This makes it possible to create architectural façades made entirely of glass blocks that promote the conservation of energy and safeguard the environment. Size: 19x19x8cm Joint width: 2mm Weight: 2.3 Kg No. Pieces/ m2: 25-27 Thermal insulation: 1.5 W/m2 °K 198 Pegasus Wave 198 Pegasus Wave metallised

Recommend

More recommend