Safety Management & Site Establishment Unit 10 – Site Temporary Works

Learning Outcomes How access to heights is gained and how structures are temporarily supported in the construction process Different styles of formwork for moulding concrete Excavation and trenching and other groundwork techniques

Introduction Temporary i.e. non-permanent works Temporary Works are installed on site to help fulfil the execution of the actual (permanent) contract works Temporary Works will be dismantled/removed from site upon fulfilment of their respective purposes. This Unit looks at four types of temporary works: o Access o Support o Protection o Groundworks (including excavations, ground supports and hydro-geological controls )

Introduction Frequently, temporary works play multiple roles but their selection is based on the primary project requirements This Unit details typical examples of the intertwined functions of temporary works to be expected on modern sites It also describes the indispensable roles that they typically function in every construction project These are roles that usually account for a significant percentage of the project’s running costs

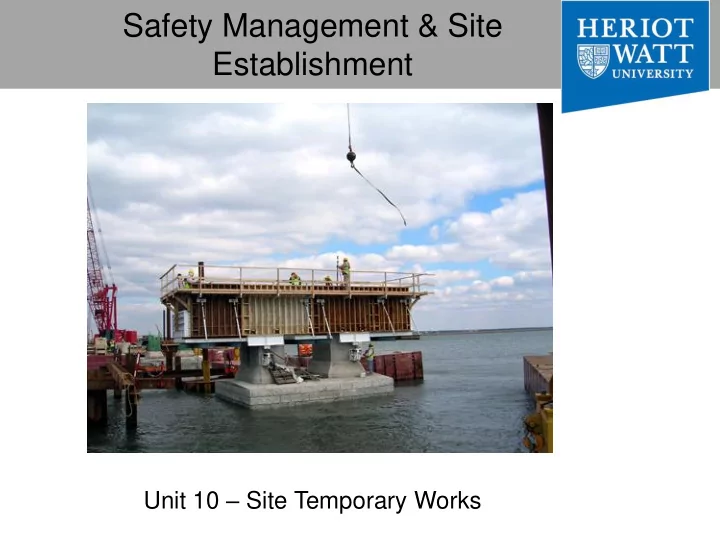

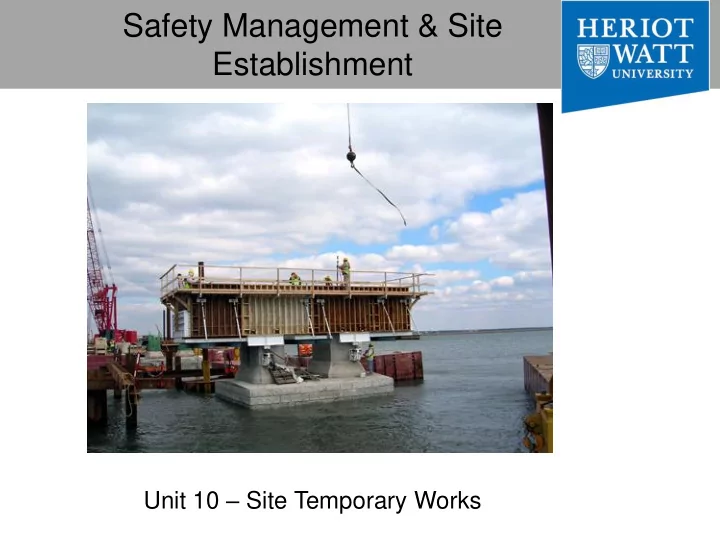

An example showcasing the extensive and combined utilities of temporary support and access structures.

Ladders Ladders should be a means of access, not a working platform Main selection considerations will reside on suitability of work, safety/durability, cost and portability. Easily available, ladders are essential as both the main and back-up tools of access

Portable, hook-on, and attachable ladders: Must be positioned so as not to tip the scaffold Hook-on and attachable ladders must be specifically designed for use with the type of scaffold on which they are used Have rest platforms provided at a max. of 10m vertical intervals

Stairway-type ladders: When positioned their bottom step is not more than 24 inches above the scaffold supporting lever. Have rest platforms at maximum vertical intervals of 12 feet Have a minimum step width of 16 inches, except for mobile scaffold stairway-type ladders, which shall have a minimum step width of 11½ inches. Have slip-resistant treads on all steps and landings. Steps and rungs of ladders and stairway-type ladders shall line up vertically with each other between rest platforms.

Step ladders • Conventional step-ladders have rectangular stiles and flat treads that are arranged to be horizontal when in use, and are restrained in position by means of stays, chains or cords. • Some variants use flat-topped rungs, while others could be of tubular construction .

Scaffolding

Common (independent) scaffolds • Despite being temporary structures, the design of scaffolds follows the principles laid down for permanent structures • There must be no deviation from sound structural principles • There is generally enough variety in standard scaffold equipment to erect a platform to suit most work requirements • Scaffolds are sometimes used for purposes other than access e.g. as falsework supporting a formwork system (to be discussed later) during concreting processes

Common (independent) scaffolds Framed

Common (independent) scaffolds Tubular

Common scaffolds Putlog A putlog scaffold consists of a single row of standards, parallel to the face of the building and set as far away from it as is necessary to accommodate a platform of four or five boards wide, with the inner edge of the platform as close to the wall as is practicable

Common scaffolds Bird-cage

Common scaffolds Birdcage • Birdcage scaffolds are commonly used for access to soffit or ceiling, as well as to provide heavy-duty and sturdy falsework support for horizontal slab casting. • Due to its modular assembly and adjustable members, the entire mass of support components can be easily shaped to provide horizontal support to massive areas. • It also assists in providing a more uniformly distributed loading pattern from the structure to the ground

Tower scaffolding • More efficient than a ladder, • All towers have to be endorsed by a professional engineer, • Most commercially produced towers can be assembled without the use of tools • Easy to transport within short distances due to the casters. 17

Truss-out scaffold • It is useful in high-rise construction, • It is useful in avoiding busy sidewalk pedestrian traffic, • Requires highly skilled personal to erect and dismantle. • There is an extra risk on H&S due to vibrations and heights etc. 18

Common scaffolds

Common scaffolds

Common scaffolds

Scaffold Class Activity: Scaffold Types; • Tower scaffolds • Common scaffolds (independent scaffold) • Putlog scaffolds • Birdcage scaffold • Truss-out scaffold Working as a group; 1. Produce a sketch drawing of the each type, highlight main elements, 2. Find 3 examples works/cases/scenarios for each, when these scaffold types would be more useful than others, 3. Identify safety and practicality concerns for each type, 4. Identify safety and practicality benefits for each type,

Hoists • Hoists are used to transport personnel and materials to different working levels • Modern hoists operate on the rack and pinion system • The hoist unit have its drive motor fitted on top of the car, along with brake and gear • This technology enables the car to climb up and down the mast at a controlled speed

Hoist Details

Mobile elevating platforms • Mobile elevating platforms are used as an alternative to scaffolds and suspended cradles (described later in the Unit) • They are particularly suitable for short duration tasks requiring high mobility of the access structures, especially so for retrofitting projects where clients are seeking short durations • The market offers a wide variety of these platforms, and guidance on specific applications should be sought from the manufacturers • There are generally two categories of mobile elevating platforms: Self-propelled and Vehicle-mounted • http://www.youtube.com/watch?v=_sqTICuXsMg

Self-propelled Platform Hoists • These can easily be manoeuvred into position by onboard controls. • They are mainly available with the following boom types, namely: scissor, telescopic and articulated Self-propelled Scissor platform Articulated-telescopic boom

Vehicle-mounted platform Hoists • These platforms come in various sizes and capacities, from small trailer- mounted platforms to large truck- mounted types • Smaller platforms are commonly used in highway and other road-related maintenance (e.g. pruning trees, servicing street-lamps etc.) • Larger versions are used where access by other methods are deemed either too expensive or time- consuming

Mast climbing platform hoists

Mast climbing platform hoists • Mast climbing platforms allow access to a localised area of a project • The rack and pinion drive gives an adjustable working platform that can be positioned exactly to suit the task in hand • Tools and materials can be carried up to the work site, together with the operatives • Mast climbing platforms are for work and access purposes only and must not be used for transporting men and materials between levels. • The three main components are; Mast(s) or tower(s); a platform capable of supporting persons & equipment and a chassis supporting the tower/mast

Mast climbing platform hoists

Suspended cradle (gondola) • Two-point adjustable suspension scaffolds, also known as ‘swing -stage scaffolds’ or ‘gondolas’, are perhaps the most common type of suspended scaffold. • Hung by ropes or cables connected to stirrups at each end of the platform, they are commonly seen to be used by window cleaners on skyscrapers, and play a prominent role in high- rise construction

Suspended cradle (gondola)

Suspended cradle (gondola)

Suspended cradle (gondola)

Abseiling • Abseiling (or industrial roped access) can provide a safe and cost-effective method of access for light work commonly of maintenance or inspection nature. • Modern roped access equipment and techniques allow fully trained specialist operatives to reach highly inaccessible locations, some of extreme conditions (e.g. from narrow mineshafts to overhanging external details under apexes of skyscrapers).

Abseiling It is a highly feasible method to consider if • Ground conditions are either unknown or unsuitable to support any vertical access (e.g. crane, scaffold & the like). • In situations when the heights of work locations cannot be reached from the ground (e.g. due to safety or physical constraints) and no strong anchorage points are available for gondolas. • Time and cost efficient for light tasks (e.g. maintenance of the main glass pyramid at Louvre Museum , France)

Recommend

More recommend