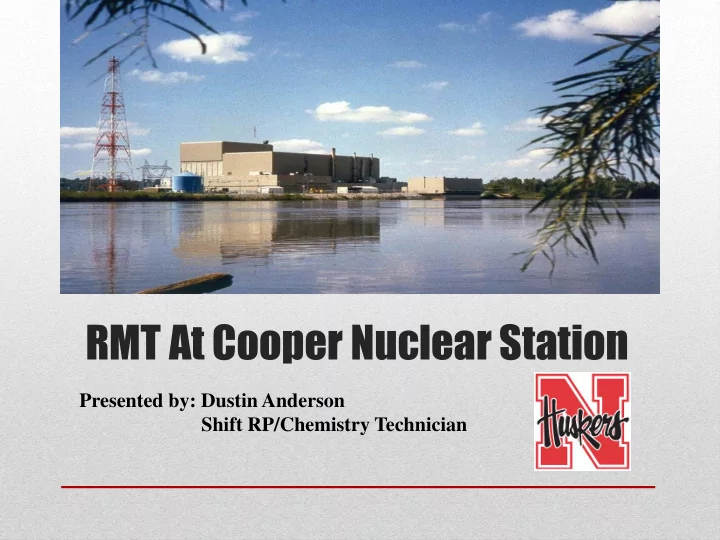

RMT At Cooper Nuclear Station Presented by: Dustin Anderson Shift RP/Chemistry Technician

Cooper’s RMT Stations allow communication with work groups via multiple devices: • Key Panels • Plant Cell Phones • (16) Telex Belt Packs • (75) Vocera Badges RMT Room Communication Capabilities

Remote Monitoring Room

• There are currently over 400 Security Center client user installations at CNS. • Layouts are created specifically for Operations, Chemistry, Engineering, Fire Watch, RP, and other applications as necessary. • CNS upgraded to the latest 5.4 version in April 2016 • Multicasting is to be implemented by RE-29 to enable the management of many simultaneous users. Security Center

Chemistry Monitoring Layout

Ops Monitoring Layout

Installed 16 new IIS P3 cameras in the TG Heater Bay during RE 28 (Fall 2014) • Used primarily by Operations to monitor feedwater heater level indicators along with Engineering system walk-downs • Also used for fire roves in LHRA areas of the TG building Panasonic 385 HD's • Our Fuel Pool Cooling Rack camera was installed in 2015 and saves Operations an estimated 150 mrem annually. • Chemistry Sample Sink Cameras – these save Chemistry approximately 300 mrem annually for obtaining reactor water readings and performing valve verifications. • CNS recently purchased an IIS wireless transmitter and 2 receivers for wireless camera applications in our ECST Room and the Refuel Floor. Recent Camera Installations

• Using remote ARM’s, RP is able to monitor plant systems and components for changing radiological conditions via ALARACast. • The Radwaste 877' Waste Surge Tank is monitored for changing radiation levels as a result of Operations routinely performing water transfers. • We’re currently working towards implementing Job Logs and RADCast prior to RE 29. ALARACast

MDRD’s/Status Board • 8 Marquees are strategically deployed throughout the plant. • These alert workers of areas with elevated dose rates and also indicate Low Dose Waiting Areas. • (2) 23" touch screen electronic status board kiosks located at RCA Access for Rad Worker self-briefings. • A status board link on the RP web page allows workers to view radiological data from their desk before entering the RCA. • New electronic trip tickets can be scanned at RCA Access to expedite entry into the RCA. Rad Worker Information

Rad Worker Information

Rad Worker Information

• Refuel Floor Cavity Work • Under Vessel Work (IRM/SRM replacements) • CRD Exchanges • ISI Inspections • Drywell Nozzle Flushing • ISFSI Campaigns • System Chemical Decontamination • TIP Maintenance and Monitoring • Fuel Sipping • Torus Diving Inspections/Desludging Remote Technology Utilization

Questions

Recommend

More recommend