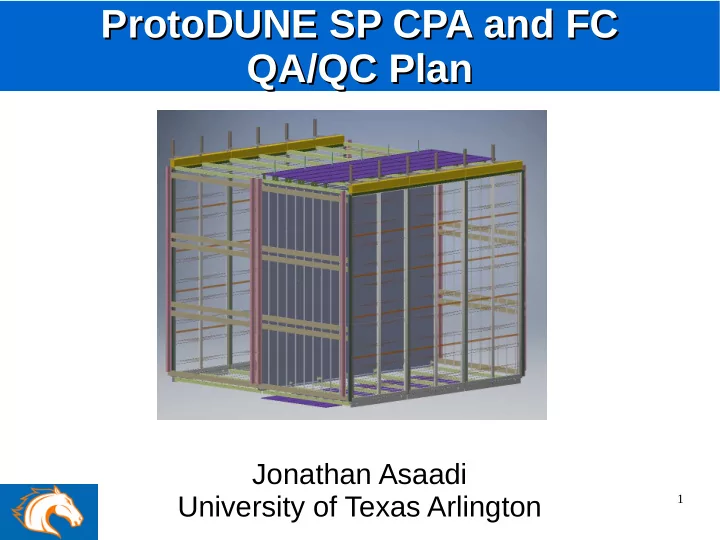

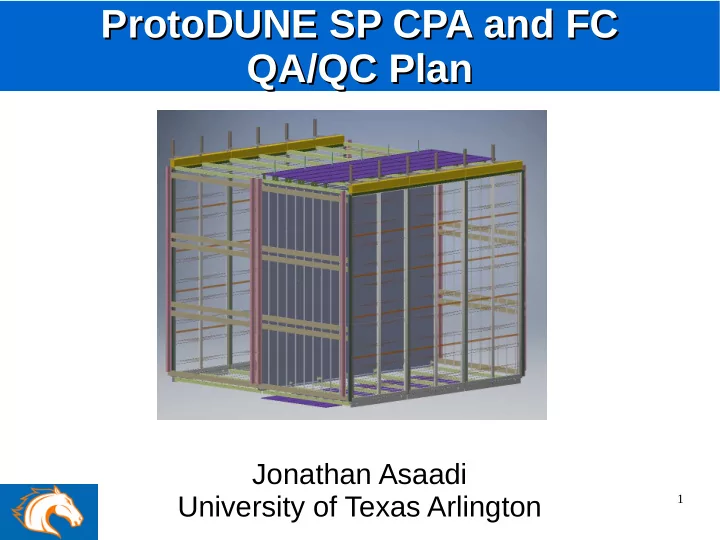

ProtoDUNE SP CPA and FC ProtoDUNE SP CPA and FC QA/QC Plan QA/QC Plan Jonathan Asaadi University of Texas Arlington 1

Overview Overview ● This talk is meant to convey some of the lessons learned from MicroBooNE and LArIAT ● This is also trying to outline various checks, tests, controls, and assurances that should be in place – Many of these tests are planned / being done / will be done during installation – Not a fully exhaustive list and will likely need to be expanded as different aspects of the detector come into sharper focus 2

QA/QC related to cleanliness QA/QC related to cleanliness Component Tests/Procedure Notes Large metal components for Soaking bath and rinse to Requires a place large enough the field cage and cathode remove grease and large to allow for cleaning and drying pieces of F.O.D. of components prior to assembly Drilled holes in all components Identifying and removing metal Need to check any internal shavings, burrs, components of large machined parts Small component (elbows, Ultra sonic bath soak Need to keep track of which screws, etc) cleaning components go where and repackaging after cleaning 3

QA/QC related to cleanliness QA/QC related to cleanliness ● The various components of the cathode and field cage will come in many pieces – Rolled form field cage tubes – G10 I beams – Plastic Caps – etc… ● Assuring these pieces meet cleanliness requirements before assembly is Soaking bath for MicroBooNE Soaking bath for MicroBooNE important Field Cage Tubes Field Cage Tubes – For MicroBooNE and LArIAT this required having access to series of ultra-sonic baths for small components – Larger soaking baths (simple green cleaning solution) for large metal pieces (field cage rings) – Checking for metal burs, foreign object debris, 4 and grease before moving the parts to

QA/QC related to cleanliness QA/QC related to cleanliness MicroBooNE DocDB 2259 can be made available to help 5

QA/QC related to components QA/QC related to components Component Tests/Procedure Notes Threaded components Application of anti-galling MicroBooNE used moly-coat coating sprayed on all bolts Interferences between mating Ensuring the correct There are often many very components bolt/nut/washer is installed in similar components and the the correct place need to have them (re)labeled following cleaning / coating and cataloged is important Identifying correct bolt head Need E-Field studies for types various types to minimize potential source for breakdown 6

QA/QC related to components QA/QC related to components ● The need for cleaning of bolts Application of moly-coat to Application of moly-coat to MicroBooNE screws MicroBooNE screws (applying anti-galling material), organizing bolts / head types is important – We had quite a few examples of bolts galling without moly-coat – Need to be careful of which bolts (size and head type) apply ● Need a comprehensive list of E-field study for different E-field study for different bolt head components bolt head components all the bolts prior to installation – Will help with vendor availability – All the parts need to be cleaned, coated, and cataloged for installation….so knowing what they 7 are in advance helps

QA/QC related to components QA/QC related to components ● Following the cleaning and coating of all the small components, making sure they are identified and cataloged for use during installation is and important control to have in place – On MicroBooNE and LArIAT we had a MicroBooNE TPC during MicroBooNE TPC during few instances where similar enough installation with very tight installation with very tight clearances clearances looking components were installed in the wrong place – These were caught during later test fits, but a better control system could have prevented this ● For something as large as (proto)DUNE and being built in different places, this a system of checks should be in place early 8 Similar enough bolt initially Similar enough bolt initially installed in the wrong position installed in the wrong position

QA/QC related to cathode QA/QC related to cathode Component Tests/Procedure Notes Flatness of assembled cathode Survey test done during This can be a time consuming construction and following process, but can be an installation essential driver of the physics so needs to be accounted for Electrical connectivity between Resistive measurement (or The application of resistive cathode components possibly small current coating will likely require a bit measurement) more thought to verify electrical connection Tests of high voltage bus Stand-alone high voltage tests The details of this component still remain a bit less clear to Assembled and installed cryo- me...so the details of the tesing tests here are not thought out yet 9

QA/QC related to cathode QA/QC related to cathode ● The MicroBooNE cathode was a similar construction (panels and tubes) ● Ensuring hole patterns (or maybe slot locations) line up for protoDUNE’s much larger structure will make installation easier ● Alignment measurements take time to do and should build in sufficient weeks for an iterative align/measure/shim/repeat 10 MicroBooNE achieved a cathode flatness of MicroBooNE achieved a cathode flatness of +/- 6 mm over the 10.3 meter length +/- 6 mm over the 10.3 meter length

QA/QC related to cathode QA/QC related to cathode ● Testing of both the mechanical and electrical performance of the HV-Bus should be done prior to installation – These tests are likely best both warm and cold ● Following installation, the verification of the HV-bus will need to be considered in the QA/QC plan – Likely as part of the overall CPA checkout post installation 11

QA/QC for resistor divider boards QA/QC for resistor divider boards Component Tests/Procedure Notes Test of individual resistor and High voltage tests to verify Tests should be done warm varistor components behavior and function and cold and results should be cataloged by components Matching components to Resistive measurement (or Test should be done warm and ensure correct tube-to-tube possibly small current cold resistance measurement) Resistors and varistor tests Spark tests and clamping Done for MicroBooNE and behavior LArIAT in the cold...but this was more for safety reasons Testing of the PCB board Destructive HV tests as well as We found problems with the baseline HV performance tests boards in LArIAT and had to go to directly soldering components onto the field cage 12

QA/QC for resistor divider boards QA/QC for resistor divider boards ● For MicroBooNE and LArIAT we built a rig to perform QC tests of the resistors at 100% of their operating voltages in the cold (open air argon dewar) – A similar rig was used for destructive tests because we could force the potential to ground quickly (simulating a spark condition) 13

QA/QC for resistor divider boards QA/QC for resistor divider boards ● The “Lighting Wheel” was a rig that Hans Jostlein built for us that allowed us to give ~2 Joule sparks to resistor and varistor components in the cold as well as test their clamping voltage and resistance after the application of sparking ● Allowed us to pick out MicroBooNE DocDB 3397 provides details of the tests varistors and resistors performed which performed the 14 best following the tests

QA/QC during initial assembly QA/QC during initial assembly Component Tests/Procedure Notes Mechanical test fits to look for High voltage tests to verify This assumes the cryostat is interferences behavior and function ready before the detector is complete….but could be done before actual installation if the schedule allows Verify electrical conductivity of High voltage tests to verify (Need to think how the the cathode behavior and function resistive coating complicates this measurement) Verify the resistor divider Apply ~1 kV to the cathode in network incremental steps and check the current is as expected as well as verify the voltage near the APA 15

QA/QC during initial assembly QA/QC during initial assembly ● In MicroBooNE and LArIAT we did a number of “mock” installations and dry runs – TPC test fits – Electronics and PMT mounting Mechanical fit tests done with Mechanical fit tests done with “dummy” motherboards on LArIAT “dummy” motherboards on LArIAT using mechanical spares – Cable routing and interference testing ● Allowed to catch problems early and anticipate changes to installation plans before the actual detector was ready to go ● The same extent of tests may TPC test fits and moch cable routing done TPC test fits and moch cable routing done not be possible for protoDUNE, with MicroBooNE and LArIAT with MicroBooNE and LArIAT but should be considered 16

QA/QC during initial assembly QA/QC during initial assembly ● Once the cathode / field cage and APA’s are installed, the electrical network should be verified – Testing the current seen when ~1kV is applied to the cathode ● “Did we connect everything MicroBooNE 1kV MicroBooNE 1kV correctly?” test of the field test of the field cage network post cage network post – Measuring the impedance installation installation between the field cage and the cryostat – Measuring the capacitance in the RC network setup by the field cage 17

Recommend

More recommend