Presented at the “2nd Annual Lab Asset & Facility Management in Pharma 2019” Conference, San Diego, CA, October 22nd, 2019 Comments from post-conference survey (conducted by conference organizer - Hanson Wade, London UK): • “Joe is very knowledgeable in his space and I found the session very educational!” “Deep dive A’s * content was very clear and pertinent. The leader was also very • hands on.” • “Joe was very hands on and highlighted the need to have collaborative efforts, esp with IT involvement. I had great takeaways from his session” • “Coming from a small biotech I had learned a lot from deep dive A as we’re a very small team, and need to be mindful of multi-facets of lab ops” • “Good pace and very nice presentation” * Deep Dive A was the brochure reference for this session 1

Presented at the “2nd Annual Lab Asset & Facility Management in Pharma 2019” Conference, San Diego, CA, October 22nd, 2019 Is made available under the Creative Commons License: 2

This document is based on a presentation delivered at the “2nd Annual Lab Asset & Facility Management in Pharma 2019” conference held in San Diego, CA, on October 22nd, 2019. It is not a verbatim transcript, but an expansion of the material presented. The presentation ran two hours, and even with that there was a limit to the depth I could go into; and even with the added material we are only touching lightly on these topics. Plus there is the ever present “I should have added…” as you move through the material, so that material has been included as well. Why is planning and technology management important? It’s the difference between building a sustainable information infrastructure that will sup- port your work, and a technology house-of-cards that’s going to fail. Among the complaints about scientifjc work - in any discipline - is that it is expensive, ineffjcient, sometimes diffjcult to reproduce and slow to execute. Part of that is due to the nature of research; you are moving into new territory and there is no map. Another aspect to it is that we have a lot of technology to work with but it isn’t used effectively. The reasons we bring advanced technologies into scientifjc work include: • Enabling us to do things we otherwise couldn’t, • Improving operational effjciency, and • Improving the return on corporate investments in scientifjc projects. Instrumentation, computers, software, networks, from a variety of vendors, are designed to do specifjc jobs but often do not to work well together. And then there are the results of scientifjc work: knowledge, information, and data; often not managed well in incompatible databases, fjles, and spreadsheets. That doesn’t include upgrades to systems and support. An answer to those issues is effective technology management and planning. That work should yield better organized systems, reduced costs, better workfmows and ROI. How do you go about it? That is what we’ll start to address in this material. If you care to discuss any of this material or learn more about the work I’m doing, please contact me through the email address “joe.liscouski@gmail.com”, or visit https://www.TheInformationDrivenLaboratory.com 3

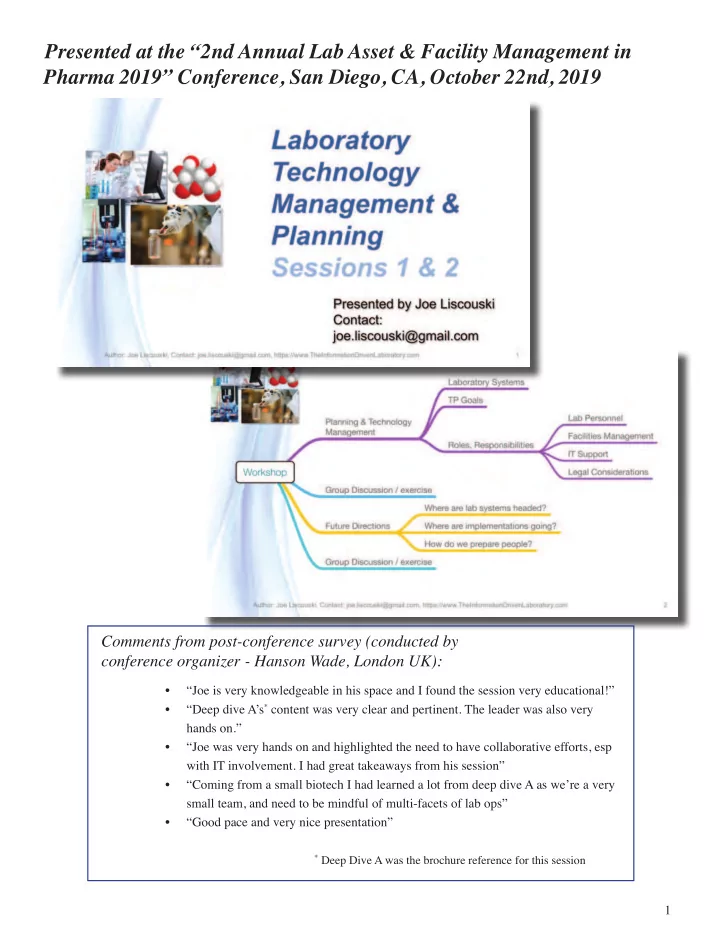

When this material was presented live, it was divided into fjve sections. The discussion sections will be omitted as will the survey responses as they were specifjc to the audience. The two remaining section are combined in this docu- ment. The fjrst portion of the material will cover the points noted on the screen in purple. 4

The second portion will cover the material underlined in yellow/gold. This is not a futuristic view of labs, but a near- term view of the direction things are likely to go, and importantly, what it is going to take to get there primarily in terms of personnel and education. There are different ways of viewing how we approach laboratory work: • It begins with questions “how do we make this work?”, “how do we ensure product quality?”, “what is this?”, “I wonder what happens if I... ?” and the list goes on. Basic and applied research, quality assurance, operating within a building complex or in the fjeld. • Then we move to place where those questions are addressed, they may be spaces with instruments from chemis- try, physics disciplines, equipment for life sciences, or rooms for thought experiment, interviews; anywhere that the questions of interest can be addressed. 5

Next we deal with the output of laboratory and scientifjc work: the gathering, analysis, reporting and management of knowledge / information / and data. This is what it comes down to: the purpose of any laboratory work is to produce knowledge, information, and data. Those elements drive decisions about the future direction of projects, product develop- ment, establishing policies, etc. Since the primary audience for this material was from the Pharma / Biotech communities the illustrations on the left were appropriate. That doesn’t diminish the applicability of this material to other scientifjc disciplines, just substitute your own equipment, be it telescopes, equipment for optics, mechanical or electrical engineering, your choice. The bottom line is that you collect measurements, those measurement go into data systems – the lab bench on the right – and are then collected into larger systems that provide for the consolidation of lab results and administrative tasks. From there they are communicated to other groups. 6

One important issue in laboratory work is the adoption of standards to facilitate the movement and processing of samples and information fmow, particularly in clinical chemistry with adoption of HL7 and other interchange standards. In the BioPharma world the microplate, shown just below the word “Laboratory” and the sample vials as standard sample containers have greatly eased the handling and processing of samples. The microplate format has led to the development of a variety of devices from different vendors that can work together because they all support the same sample format. This includes plate handing for: sample preparation, move- ment, sealing (to prevent evaporation), spectrometers, imaging, reagent addition, and so on. This has facilitated the devel- opment of robotics systems from companies such as Agilent, and complete processing systems from Douglas Scientifjc. In the latter case instead of physical plates the vendor uses plate-like formats on tapes that are part of a high-throughput processing system. 7

The standardization of vial geometries has permitted the development of systems like Baytek International’s Tur- boTube which uses pneumatic tubing to move sample vials between stations, holding areas (Sample Bank) and disposal (Sample Drop). MagneMotion (Devens, MA) has created a sample tube carrier system for routing samples through the lab. These kinds of options mean that considerable planning and attention has to be paid to the physical layout of laboratory spaces if technologies like these are under consideration. 8

Once vendors began to address the need for computerized data collection and processing at the instrument (Lab Bench) level, they turned their attention to “higher level data structures” and lab management systems. Beginning with Laboratory Information Management Systems (LIMS) which focuses on sample tracking and results management in test- ing labs, they then turned to scientifjc fjle management (documents, images, fjles, etc.) in the form Scientifjc Document Management Systems (SDMS), and Electronic Laboratory Notebooks (ELNs) in research. Those few sentences gloss over a lot of history and overlapping product introductions and replacements, but that is beyond the scope of what is being covered here, except for… Except for the fact that the various vendors were watching each other, looking to see what types of functional- ity existed and whether or not they could incorporate similar functions into their products. The end result is some basic product classifjcations, having a primary emphasis (LIMS, ELN, SDMS, instrument data systems) with a lot of overlap in functions, but differing in how those functions are implemented and what you have to do to make use of them. The details are important and beyond the scope of this document, but it does mean that you have to understand those details and account for them in your planning efforts. See items one and two in the references section. 9

Recommend

More recommend