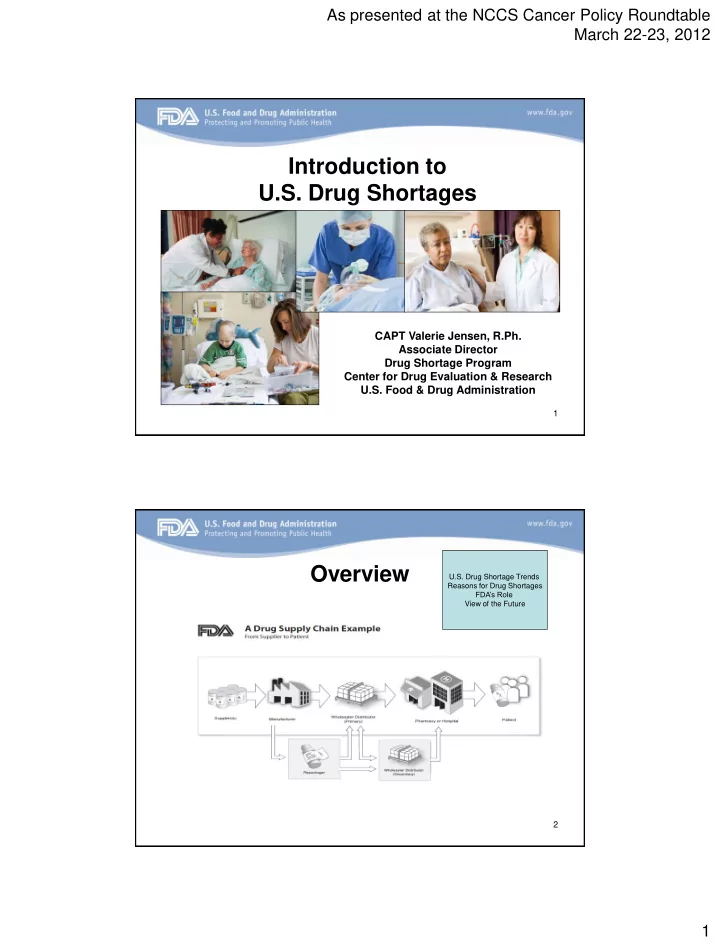

As presented at the NCCS Cancer Policy Roundtable March 22-23, 2012 Introduction to U.S. Drug Shortages CAPT Valerie Jensen, R.Ph. Associate Director Drug Shortage Program Center for Drug Evaluation & Research U.S. Food & Drug Administration 1 Overview U.S. Drug Shortage Trends Reasons for Drug Shortages FDA’s Role View of the Future 2 1

As presented at the NCCS Cancer Policy Roundtable March 22-23, 2012 Drug Shortage Program History • Center for Drug Evaluation & Research Who works on this? – Drug Shortage Program (DSP) began in 1999 Office of New Drugs – Today have 11 full time staff Office of Chemistry Office of Generic Drugs – Many others in involved Office of Compliance Field Inspectors • Mission: address potential and actual drug MANY OTHERS! shortages – Facilitate prevention and resolution of shortages by collaborating with FDA experts, industry, and external stakeholders – Inform the public – Outreach to healthcare professional organizations, patient groups and other stakeholders 3 Growing problem – and FDA response • FDA website updated daily • Staffing and management coordination • Public reports encouraged – industry reports of problems even more so • Public workshop September 26, 2011 • Collaboration on system fixes – American Society of Healthcare Pharmacists (ASHP) – Industry (GPHA, PhRMA, BIO) • Prevent and mitigate individual shortages 4 2

As presented at the NCCS Cancer Policy Roundtable March 22-23, 2012 FDA Authorities are very limited What we can’t require What we can require • Notification by sole • A company to make a source manufacturers* drug or make more – For discontinuance of • Notification of most product production delays, etc. – 6 months in advance • How much and to whom – No penalty for not reporting drug is sold or distributed • Notification of manufacturing changes FDA Drug Shortages Program is largely depends on voluntary notification by manufacturers and the public. 5 DISCONTINUANCE OF A LIFE SAVING PRODUCT SEC. 506C. [ 21 U.S.C. 356c] DISCONTINUANCE OF A LIFE SAVING PRODUCT. (a) IN GENERAL. — A manufacturer that is the sole manufacturer of a drug — (1) that is — (A) life-supporting; (B) life-sustaining; or (C) intended for use in the prevention of a debilitating disease or condition; (2) for which an application has been approved under section 505(b) or 505(j); and (3) that is not a product that was originally derived from human tissue and was replaced by a recombinant product, shall notify the Secretary of a discontinuance of the manufacture of the drug at least 6 months prior to the date of the discontinuance. • See also 21CFR 314.81(b)(3)(iii) 6 3

As presented at the NCCS Cancer Policy Roundtable March 22-23, 2012 All U.S. Shortages Sterile Injectables 300 250 250 178 Number 200 157 150 110 90 100 61 56 50 0 2005 2006 2007 2008 2009 2010 2011 Year 7 Sterile Injectibles : > 75% lapsed product quality & production Product Quality 54% Delays, capacity and loss of manufacturing site 25% Discontinuations 11% Raw Materials 5% New demand 4% Other 2% 8 4

As presented at the NCCS Cancer Policy Roundtable March 22-23, 2012 2011 Shortage Data • Over 250 shortages reported in 2011 • High percentage are sterile injectable products – Treatments for cancer, anesthesia, serious illness – Highly specialized manufacturing – High risk to patient if not meticulous When there are quality or production problem for a sterile injectable drug, a shortage is almost always results 9 Reasons for Shortages: Sterile Injectibles Report by Assistant Secretary for Planning & Evaluation 2011 • State of the industry – Seven (7) manufacturers make up most of market – Contract manufacturers – firms contract out manufacturing as well as acting as contract manufacturers • Lack of redundancy – Multiple products made on existing manufacturing lines – 24/7 production with no ―cushion‖ • Complex manufacturing process – No simple fixes – Problems typically affect multiple products • Investment economics question – e.g., leucovorin injection < $5.00/vial 10 5

As presented at the NCCS Cancer Policy Roundtable March 22-23, 2012 How does FDA fit? • Patient care is our #1 concern • We get involved when we are informed • Seek ways to prevent & mitigate shortages – Secondary response to industry problem – Find root cause and get manufacturer on track • Some shortages can be prevented, but not all – Unforseen breakdown in manufacturing system – Longstanding quality manufacturing problems • Some can be addressed quickly, others not – Risks to the patient always considered 11 Quality and Manufacturing Examples • Sterility - bacterial and mold contamination • Particles of foreign matter – glass, metal and fibers in vials • Crystallization of the active ingredient • Precipitate formation – due to reaction with raw materials or container/stopper with the drug • New impurities or degradants • Equipment breakdown • Natural disasters 12 6

As presented at the NCCS Cancer Policy Roundtable March 22-23, 2012 FDA’s Approach to Prevention/Mitigation • Consider medical necessity • Risk/Benefit of the drug always considered • Do everything possible within our authority to continue availability while minimizing risk to patients. • Work with firm to address – We can advise, assist and expedite, but only the manufacturer can fix the problem • Be flexible and creative – and fast 13 Medical Necessity • A medically necessary drug product is a product that is used to treat or prevent a serious disease or medical condition for which there is no other alternative drug, available in adequate supply, that is judged by medical staff to be an adequate substitute CDER Manual of Policies and Procedures on Drug Shortage Management 6003.1 http://www.fda.gov/downloads/AboutFDA/CentersOffices/CDER/ManualofPoliciesPro cedures/UCM079936.pdf 14 7

As presented at the NCCS Cancer Policy Roundtable March 22-23, 2012 FDA Tool Box • Regulatory discretion: allow manufacture of medically necessary product(s) to continue – Minor, low risk issues usually best suited for this tool – In some cases require additional safety controls • Filters packaged with product; extra testing at plant; 3 rd party oversight of production; special instructions for safe use • Request other firms to ramp up manufacturing. • Expedite any review of company proposals – New manufacture site, increased expiry, new raw material source, changes in specifications, etc. • In rare cases, temporary importation from unapproved sources – 2010 temporary importation of propofol – 2011 temporary importation of foscarnet, ethiodol, thiotepa, norepinephrine, Xeloda, levoleucovorin, leucovorin – 2012 temporary importation of Lipodox, methotrexate preservative free vials 15 38 Shortages Prevented in 2010 • All due to firms notifying FDA of problems early • 16 through regulatory discretion – Risk of quality/manufacturing issue able to be mitigated and was outweighed by benefit of the drug • 13 through expedited review – New manufacturing sites, suppliers, etc. • 8 through encouraging other firms to ramp up • 1 through communication with DEA regarding firm ’ s need for controlled substance quota increase 16 8

As presented at the NCCS Cancer Policy Roundtable March 22-23, 2012 2011 Data Higher – Executive Order President’s Executive Order issued 10/31/11 encouraged more voluntary reporting by manufacturers • 6 fold increase in notifications of potential shortages – normally received 10/month on average in 2010 and now receiving over 60 notifications per month) • Total of 195 shortages prevented in 2011 • In 2012, 18 shortages prevented as of February 9, 2012 17 Shortages can’t always be prevented • Unanticipated problems, such as a manufacturing line breakdown or natural disaster • Manufacturer(s) may not be able to make up production shortfall • Risks are significant and would cause patient harm (e.g. sterility problems) • FDA will work with company to encourage smart distribution – No easy answers on how to do this well 18 9

As presented at the NCCS Cancer Policy Roundtable March 22-23, 2012 The Future • FDA Drug Shortage work will continue – Multidisciplinary: clinicians, pharmacists, chemists, biotechnology, regulatory and manufacturing – We can only prevent shortages if problems are reported – Public communication of existing shortages • Congress discussing new legislation – Would REQUIRE broader reporting by industry to FDA • Public expects and deserves high quality drugs • Must have industry commitment to culture of quality manufacturing – Many firms are building new plants today – Need better methods and redundancy – Promptly report and correct even small problems 19 Thank You • FDA drug shortage website is: http://www.fda.gov/Drugs/DrugSafety/default.htm • To report shortages our e-mail account is Drugshortages@fda.hhs.gov • FDA Webinar on Prescription Drug Shortages Sept. 30, 2011, http://www.fda.gov/AboutFDA/Transparency/Basics/ ucm272223.htm 20 10

Recommend

More recommend