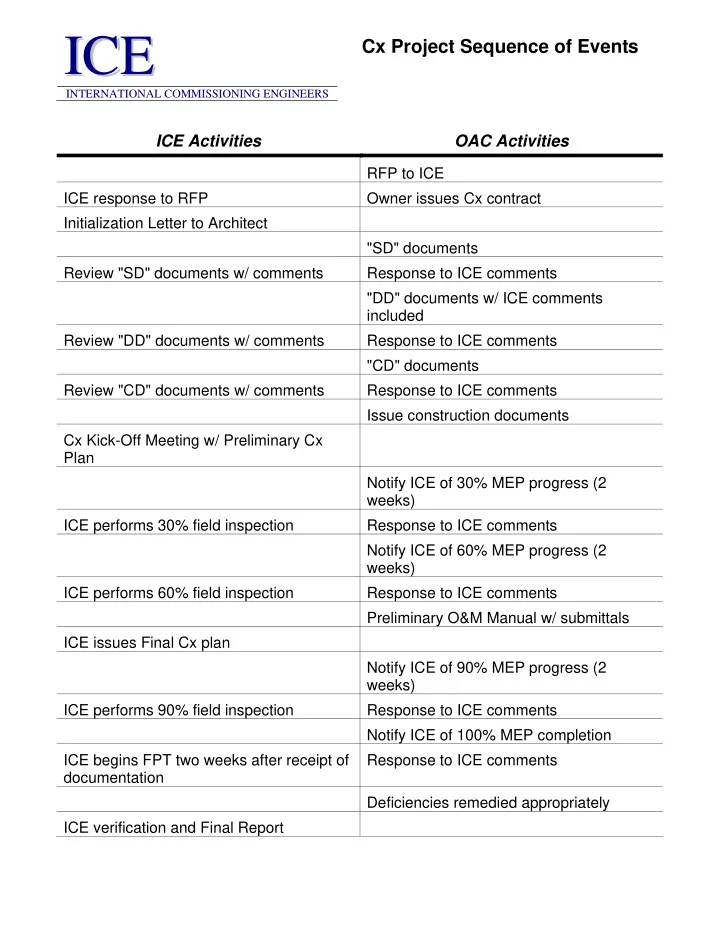

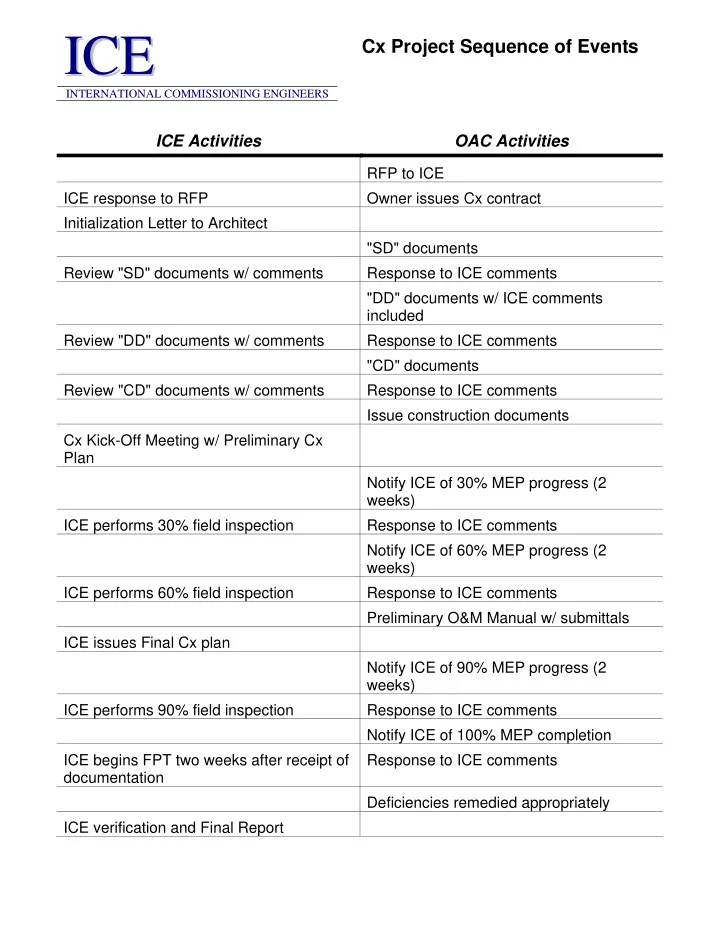

IC CE E I Cx Project Sequence of Events INTERNATIONAL COMMISSIONING ENGINEERS ICE Activities OAC Activities RFP to ICE ICE response to RFP Owner issues Cx contract Initialization Letter to Architect "SD" documents Review "SD" documents w/ comments Response to ICE comments "DD" documents w/ ICE comments included Review "DD" documents w/ comments Response to ICE comments "CD" documents Review "CD" documents w/ comments Response to ICE comments Issue construction documents Cx Kick-Off Meeting w/ Preliminary Cx Plan Notify ICE of 30% MEP progress (2 weeks) ICE performs 30% field inspection Response to ICE comments Notify ICE of 60% MEP progress (2 weeks) ICE performs 60% field inspection Response to ICE comments Preliminary O&M Manual w/ submittals ICE issues Final Cx plan Notify ICE of 90% MEP progress (2 weeks) ICE performs 90% field inspection Response to ICE comments Notify ICE of 100% MEP completion ICE begins FPT two weeks after receipt of Response to ICE comments documentation Deficiencies remedied appropriately ICE verification and Final Report

IC CE E I Cx Project Milestones INTERNATIONAL COMMISSIONING ENGINEERS 1. Kick-Off Meeting – Should be no later than the progress meeting prior to the beginning of MEP rough-in. • ICE will provide a commissioning process overview for the contractors. The Preliminary Commissioning Plan will be discussed and distributed. 2. 30% MEP Inspection - Installation of MEP systems is approximately 30% complete. Ductwork is 50% installed with fire/smoke dampers and access doors installed in main trunks. DALT is in progress for major high pressure duct sections. No insulation should be installed. The CxA and TAB sub-contractor should have a set of approved submittals. Electrical rough-in should be well underway. Sprinkler bulk mains should be installed. • ICE will inspect for duct material thickness, MVDs meeting specs and installed appropriately, square turn elbow turning vanes installed per SMACNA, transition fittings, specified seismic supports, all materials and installed systems are protected against dirt, debris and weather, conduit installed parallel and perpendicular to building lines, etc. 3. 60% MEP Inspection - Installation of MEP systems is approximately 60% complete. All deficiencies from the 30% MEP Inspection have been remedied appropriately with written confirmation to the CxA. Major equipment is in place. Ductwork, piping and electrical rough-ins are 90% complete. Control contractor has presented sample BAS graphics for review. Start-up verification forms are in use to prepare start-up plan. Piping systems pressure tests are complete. Hydronic systems cleaning and flushing plan is in place. • ICE will inspect for flexible-connectors to HVAC equipment meet spec., flexible ductwork meets specified length, NEC and other code clearances are met, systems are clean and protected, main electrical cables are specified size with proper terminations, etc. 4. 90% MEP Inspection - Installation of MEP systems is approximately 100% complete. All deficiencies from the 60% MEP Inspection have been remedied appropriately with written confirmation to the CxA. The Architect and Engineers have performed their final inspections with deficiency lists. All equipment start-up is complete with SUV forms signed and delivered to the CxA. Controls are in place and operational with point-to-point verification complete. TAB is ready to begin. • ICE will inspect for equipment start-up and access, Controls completion, TAB readiness which includes clean filters in all equipment. 5. Cx/FPT - Once ICE receives the preliminary TAB report, ICE will require a minimum of two weeks to schedule FPT. • ICE will review the TAB report and other documentation for completeness and possible modification of FPT planning, visit the site for the 100% MEP Inspection (if appropriate) and issue a final timeline of FPT activities. The GC will schedule the MEP sub-contractors to support the FPT activities (other interested parties should be notified as appropriate).

IC CE E I System Readiness for Cx / FPT INTERNATIONAL COMMISSIONING ENGINEERS I. PREREQUISITES – Cx / FPT • Only Whole Systems Can Properly Undergo Cx / FPT! • WHOLE SYSTEMS = ? � = Entire Facility + All Associated MEP & Controls Support Equipment. � = Individual, Stand Alone MEP systems that can be isolated with respect to all other systems and independently tested without being impacted by systems under construction. � Example - Individual campus building AHU systems; individual building zone AHU Systems, etc. • Test and Balance (TAB) Fieldwork Completed & Hard Copy of Final TAB Data Submitted � Prerequisites Necessary for TAB to be Completed � Whole systems are preferred but not absolutely necessary. � Equipment / Systems have undergone proper startup & checkout by mfr. or contractor. � All controls for subject equipment have undergone functional & point-to-point checkout by the controls technician. � All deficiencies identified by TAB agency are corrected or satisfactorily addressed. II. MINIMUM SYSTEM READINESS REQUIREMENTS � All ICE pre-functional checklists (from Cx Plan) have been signed, dated and returned to ICE, at least two weeks prior to the scheduled start date for Cx / FPT, verifying that all equipment / systems (whole systems only) are truly ready for Cx / FPT. � ICE prepares startup forms and includes them in Cx Plan. � Method of protecting Owner. � Signed form provides a written record of equipment / system readiness for Cx / FPT. � Forms include steps ICE believes are the minimum required to ensure equipment has undergone proper startup. � If ICE subsequently proves that systems were not ready, the signed forms are the legal basis for the Owner to recover costs via back-charging the offending subcontractor. • Hard copy of final TAB data delivered to ICE at least two weeks prior to the scheduled start date for Cx / FPT. • The facility fire alarm (FA) inspection needs to have been completed, approved and report issued. • The facility elevator inspection (if applicable) needs to have been completed, approved and report issued. • The emergency generator (EMG) test (if applicable) needs to have been completed, approved and report issued. • OPTIONAL BUT RECOMMENDED: The mechanical contractor should implement system functional performance checks in advance, utilizing the FPT forms provided in ICE’s Cx plan, to ensure that all equipment and systems are fully functional. III. MYTH-BUSTING • Myth # 1 – Missing or incomplete Checklists and documentation does not generate lost time and additional costs. � Arriving to begin Cx / FPT when systems are not ready forces an unnecessary additional visit and plays havoc with project scheduling. • Myth #2 - The purpose of Cx / FPT is to help the GC and PM push the project towards completion. � Though this happens often, the purpose of Cx / FPT is to verify that all MEP systems are functioning properly and in accordance with the design intent. � Using ICE for this purpose results in two (2) certainties. � The project will take longer than expected and require additional trips by ICE to verify correction of deficiencies and resume Cx / FPT. � The project will cost more than originally anticipated. 655 Hembree Parkway, Suite A • Roswell, Georgia 30076 • Phone: 678-366-2108 • Fax: 678-366-2227 • email: ice@iceagents.com

Recommend

More recommend