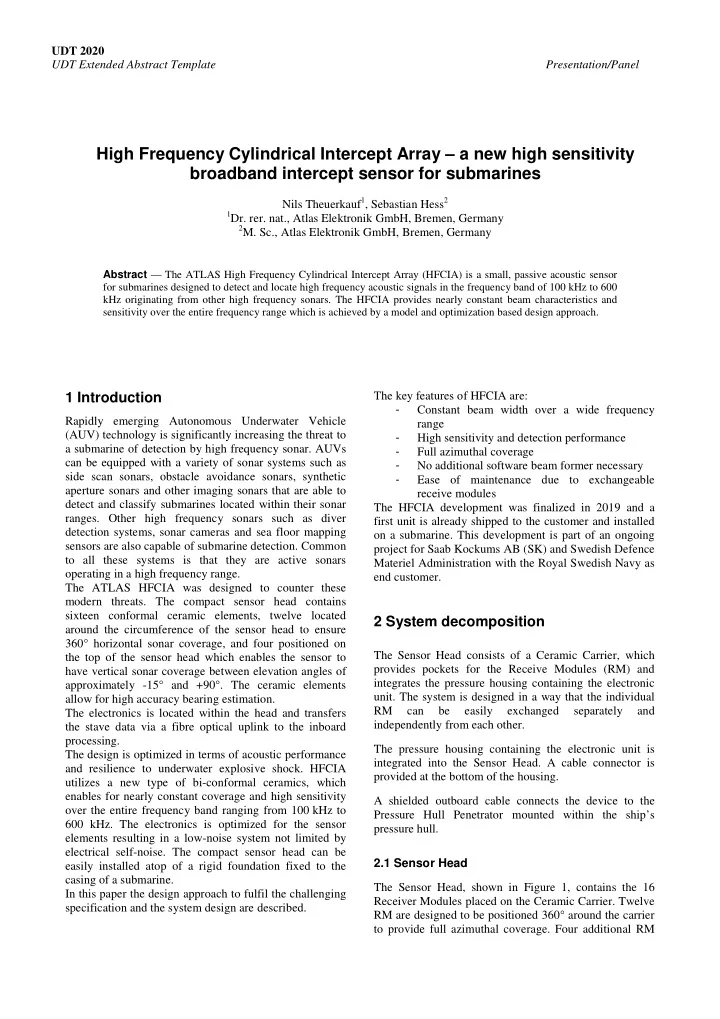

UDT 2020 UDT Extended Abstract Template Presentation/Panel High Frequency Cylindrical Intercept Array – a new high sensitivity broadband intercept sensor for submarines Nils Theuerkauf 1 , Sebastian Hess 2 1 Dr. rer. nat., Atlas Elektronik GmbH, Bremen, Germany 2 M. Sc., Atlas Elektronik GmbH, Bremen, Germany Abstract — The ATLAS High Frequency Cylindrical Intercept Array (HFCIA) is a small, passive acoustic sensor for submarines designed to detect and locate high frequency acoustic signals in the frequency band of 100 kHz to 600 kHz originating from other high frequency sonars. The HFCIA provides nearly constant beam characteristics and sensitivity over the entire frequency range which is achieved by a model and optimization based design approach. 1 Introduction The key features of HFCIA are: Constant beam width over a wide frequency - Rapidly emerging Autonomous Underwater Vehicle range (AUV) technology is significantly increasing the threat to High sensitivity and detection performance - a submarine of detection by high frequency sonar. AUVs Full azimuthal coverage - can be equipped with a variety of sonar systems such as No additional software beam former necessary - side scan sonars, obstacle avoidance sonars, synthetic Ease of maintenance due to exchangeable - aperture sonars and other imaging sonars that are able to receive modules detect and classify submarines located within their sonar The HFCIA development was finalized in 2019 and a ranges. Other high frequency sonars such as diver first unit is already shipped to the customer and installed detection systems, sonar cameras and sea floor mapping on a submarine. This development is part of an ongoing sensors are also capable of submarine detection. Common project for Saab Kockums AB (SK) and Swedish Defence to all these systems is that they are active sonars Materiel Administration with the Royal Swedish Navy as operating in a high frequency range. end customer. The ATLAS HFCIA was designed to counter these modern threats. The compact sensor head contains sixteen conformal ceramic elements, twelve located 2 System decomposition around the circumference of the sensor head to ensure 360° horizontal sonar coverage, and four positioned on The Sensor Head consists of a Ceramic Carrier, which the top of the sensor head which enables the sensor to provides pockets for the Receive Modules (RM) and have vertical sonar coverage between elevation angles of integrates the pressure housing containing the electronic approximately -15° and +90°. The ceramic elements unit. The system is designed in a way that the individual allow for high accuracy bearing estimation. RM can be easily exchanged separately and The electronics is located within the head and transfers independently from each other. the stave data via a fibre optical uplink to the inboard processing. The pressure housing containing the electronic unit is The design is optimized in terms of acoustic performance integrated into the Sensor Head. A cable connector is and resilience to underwater explosive shock. HFCIA provided at the bottom of the housing. utilizes a new type of bi-conformal ceramics, which enables for nearly constant coverage and high sensitivity A shielded outboard cable connects the device to the over the entire frequency band ranging from 100 kHz to Pressure Hull Penetrator mounted within the ship’s 600 kHz. The electronics is optimized for the sensor pressure hull. elements resulting in a low-noise system not limited by electrical self-noise. The compact sensor head can be 2.1 Sensor Head easily installed atop of a rigid foundation fixed to the casing of a submarine. The Sensor Head, shown in Figure 1, contains the 16 In this paper the design approach to fulfil the challenging Receiver Modules placed on the Ceramic Carrier. Twelve specification and the system design are described. RM are designed to be positioned 360° around the carrier to provide full azimuthal coverage. Four additional RM

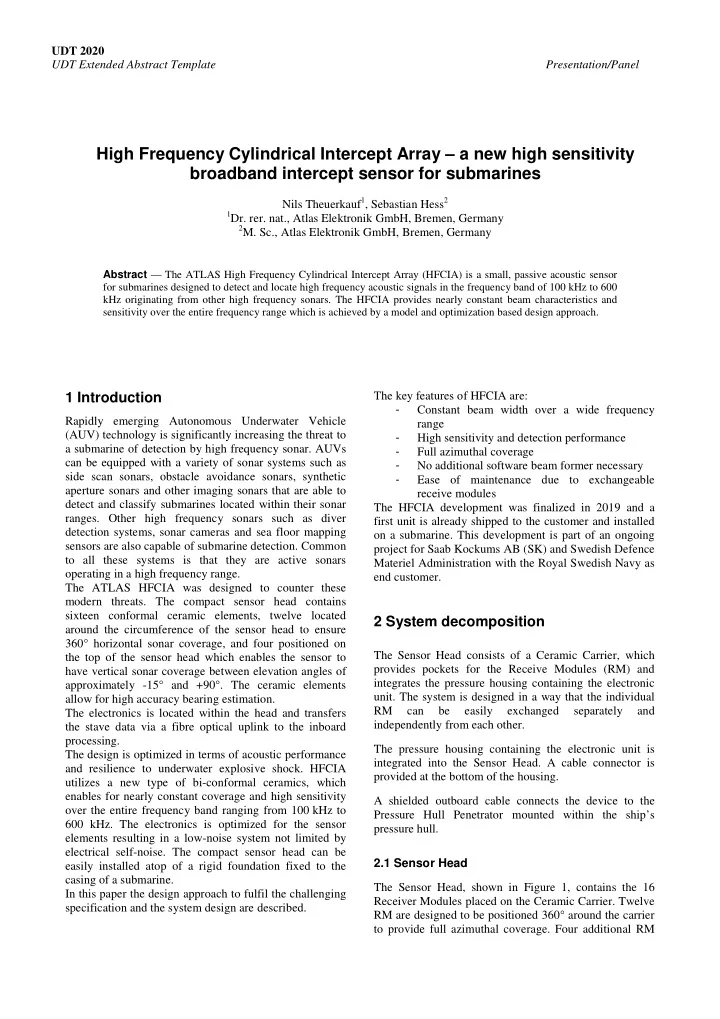

UDT 2020 UDT Extended Abstract Template Presentation/Panel 2.3 Sensor Electronic located on the top of the Sensor Head are mounted in a pyramid like arrangement to provide adequate coverage The Sensor Electronic is located in the pressure resistant of the upper hemisphere (see Fig. 1). housing which is a part of the Sensor Head. The Sensor Section 3 provides examples of the acoustic coverage Electronic is designed to process the analogue signals obtained with this arrangement of Receiver Modules. from the 16 receive ceramics. Therefore, it contains a Low Noise Amplifier (LNA), fully integrated Voltage Controlled Amplifier (VCA) with gain and filter functions, Analogue Digital Converter (ADC) and a Field Programmable Gate Array (FPGA) for control and transfer via a fibre optical uplink. The electronic unit features signal conditioning like a/d- conversion, various filters and a down sampling for a high data output. To improve the SNR of the received signals, an automatic gain control amplifies the dynamic range of the ADC to attenuate high level signals and amplify low level signals. This prevents the HFCIA from clipping when active sonars ping in close distance. Fig. 1. HFCIA Sensor Head 3 Design approach The design of the HFCIA presented numerous technical challenges to be solved. At the beginning of the design phase a selection of possible concepts was identified and these concepts were subsequently assessed in terms of achieving the design goals, whilst minimizing the technological risk. This resulted in a receive module with a bi-conformal surface. Main acoustic requirements for the development were: Reception frequency band: 100 to 600 kHz - Vertical detection sector θ -3dBV : ≥ 7.5° in band - Full coverage of the azimuth - No limitation by own noise - Fig. 2. Modular design of the HFCIA Sensor Head Good horizontal bearing estimation better than 10° - A further design goal was that the HFCIA shall enable a 2.2 Receiver Module horizontal bearing estimation by using a 12 stave cylindrical array. Therefore, the sensitivity of the The Receiver Module (see Figure 3) is the acoustic individual staves should decrease continuously with the functional unit of the HFCIA. This functional unit azimuth angle to facilitate the bearing estimation converts the acoustic signal into an electrical signal. algorithm. It consists of a composite ceramic which is embedded For a high detection range the ceramic in combination into a water-proof housing. The design allows for an easy with the electronics shall not be own noise limited. exchange of Receive Modules and provides sufficient Numerical optimization was used to minimize the impact support to the ceramic element during explosive shock. of electrical self-noise. The model incorporates electro- acoustical properties of the sensor and the properties of the electronics. This facilitates constant coverage and low self-noise over the wide frequency range. This modelling approach reduced the number of test samples to be produced during the development and helped to speed up the development process. The initial validation and the following automatization of the model (rapid modelling approach) was an important step to reach the final design. The identified performance benchmarks met by the design are: Fig. 3.. Image of HFCIA Receive Module

Recommend

More recommend