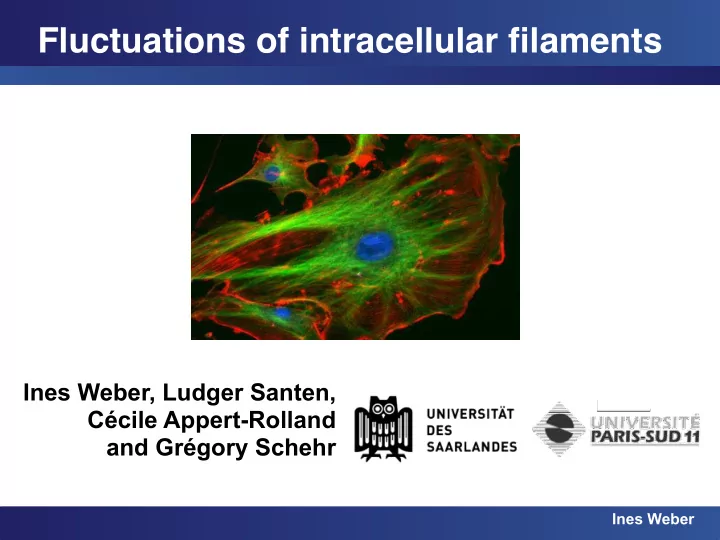

Fluctuations of intracellular filaments Ines Weber, Ludger Santen, Cécile Appert-Rolland and Grégory Schehr Ines Weber

Introduction Microtubule structure • Tubulin heterodimers (8 nm) polymerize to form polarized protofilaments • 13 protofilaments wrap in a helical way into a hollow cylinder • stiff filaments which are resistant to mechanical stress like stretching and bending: B. Alberts et al., ‣ bending rigidity k ≈ 10 − 24 Nm 2 Molecular Biology of the Cell (Garland Science, 2002) ‣ elasticity ǫ ≈ 1GPa • MTs bend on a typical scale of millimeters under thermal fluctuations ‣ persistence length L p ≈ 1mm Ines Weber

Introduction Microtubule dynamics in vivo Highly bent microtubules in cells, bending on a much smaller length scale ‣ Non-equilibrium effect otherwise fluctuations would have to be on the scale of the persistence length Active processes inside cells: • Microtubule fluctuations due to activity of molecular motors Ines Weber

Introduction Molecular motors Walk along filaments by converting ATP into mechanical work. • unidirectional movement with discrete steps • Kinesin : plus-end directed Dynein : minus-end directed • load-dependent: reduced velocity for big forces, motor stops at stall force F s ≈ 3 pN http://multimedia.mcb.harvard.edu/ and detaches from the filaments at F d ≈ 6 pN ‣ motor proteins can drag intracellular cargo along filament or link two filaments Ines Weber

Modelling of microtubule fluctuations Microtubule Molecular motors • semi-flexible filament modelled • 2 types with oppositely directed as a worm-like chain motion • stochasticity & processivity � L � 2 � ∂θ H = k , • finite force & path length ds ∂ s 2 • flexible coupling to the filament 0 • no tensibility • periodic boundary conditions load force L spring = L max L spring < L max L spring = 0 Ines Weber

Modelling of microtubule fluctuations Estimation of filament‘s shape t i +1 t i − 1 t i Segment defines filament shape between u i ( t ) sites and . t i +1 t i � t i +1 N v i � 2 dt x i � Bending energy ∂ 2 � E = k t u i ( t ) t i i =1 v i +1 At mechanical equilibrium: F ∼ ∂ 4 t u i ( t ) u i ( t ) = a i t 3 i + b i t 2 i + c i t i + d i with a, b, c, d = f ( x i , x i +1 , v i , v i +1 ) ⇔ E = x t Bx − 1 4 Λ t ˜ The energy writes with , . A − 1 Λ A, B = F ( t ) Λ = Λ ( t, x ) Ines Weber

Modelling of microtubule fluctuations Force dependent rates attachment rate w a ( F ) = w a 0 rapid, step-like � � 1 − F hopping rate force fluctuations p ( F ) = p 0 F s � | F | � detachment rate w d ( F ) = w d 0 exp F d Ines Weber

Influence of the filament rigidity Dynamic of the filament k ≪ 1 k ≫ 1 k ≈ 1 flexible regime semi-flexible regime stiff regime vertical distance [10nm] vertical distance [10nm] vertical distance [10nm] 30 30 30 20 20 20 10 10 10 0 0 0 -10 -10 -10 -20 -20 -20 -30 -30 -30 0 0 0 4 5 4 5 4 5 5 × 10 1 × 10 5 × 10 1 × 10 5 × 10 1 × 10 time [sec] time [sec] time [sec] Ines Weber

Results Velocity distribution - influence of the rigidity 1 k = 0.001 0,8 k = 0.01 k = 0.1 k = 1 0,6 CDF k = 10 k = 100 ‣ gaussian fluctuations 0,4 k = 1000 ‣ small rigidity causes high velocity ‣ motors cannot induce global drift 0,2 0 -0,1 -0,05 0 0,05 0,1 velocity [nm/s] Ines Weber

Long-range correlations Non-stationary stochastic time series - trajectory of the filament x ( t ) n − 1 x n ( t ) = 1 standard deviation about the moving average � ˜ x ( t − k ) σ MA n k =0 � N max � 1 � � x n ( t )] 2 σ MA = [ x ( t ) − ˜ � N max − n t = n exhibits a power law dependence , with the σ MA = D n H H σ MA Hurst Parameter and the diffusion coefficient. D The exponent corresponds to a negative correlation for , 0 < H < 0 . 5 positive correlation for , 0 . 5 < H < 1 uncorrelated Brownian process for . H = 0 . 5 Ines Weber

Long-range correlations Hurst Parameter Diffusion coefficient 0,58 L = 50 L = 50 0,1 L = 100 L = 100 0,56 L = 200 L = 200 Diffusion coefficient D Hurst Parameter H 0,54 0,52 0,5 0,01 0,48 0,46 0,44 0,42 0,4 0,001 1 1 0,001 0,01 0,1 10 100 1000 0,001 0,01 0,1 10 100 1000 filament rigidity k filament rigidity k •quasi Brownian motion •Transition from semi-flexible •maximal cooperation of to stiff regime at k ≈ 30 motors at k ≈ 30 Ines Weber

First Summary Microtubule fluctuations • semi-flexible filament + uncoordinated motors • sequential update • velocity depends on the stiffness and on the force ratio • quasi Gaussian fluctuations, H ≈ 0 . 5 • diffusion coefficient indicates at least two fluctuation regimes ➡ Motors are not able to induce global drift and persistent movement. Coordinated motor motion needed ? • semi-flexible filament + coordinated motors ➡ parallel update • Tug-of-war model inspired by Müller, Klumpp, and Lipowsky Ines Weber

Tug-of-war model Cargo transport is provided by a tug-of-war between two motor species � � 1 − F for F ≤ F s p F , F s load-dependent velocity p = � � 1 − F for F ≥ F s p B , F s binding to the cargo w a � | F | � load-dependent unbinding w d = w d 0 exp F d deterministic cargo motion Tug-of-war as a cooperative mechanism for bidirectional cargo transport by molecular motors. Müller, Klumpp, Lipowsky, PNAS,2008 Ines Weber

Tug-of-war model Cargo transport is provided by a tug-of-war between two motor species • no motion equal number of bound + and - motors ‣ small fluctuations around initial position • fast + and - motion with interspersed pauses both motor types are bound ‣ cargo switches between fast upwards/ downwards drift with fluctuating pauses Tug-of-war as a cooperative mechanism for bidirectional cargo transport by molecular motors. Müller, Klumpp, Lipowsky, PNAS,2008 Ines Weber

Tug-of-war model for filaments Model f = F s • stiff filaments and large force ratio F d • parallel update ‣ ATP-ADP cycle defines intrinsic time scale ‣ collective motor motion and attachment, hierarchic detachment k = 1000, f = 5 • no deterministic filament motion *parallel, ** sequential 1 L = 50* 0,8 L = 100* L = 200* L = 50** 0,6 L = 100** CDF L = 200** filaments become more active 0,4 0,2 -0,005 0 0,005 velcocity [nm/s] Ines Weber

Tug-of-war model for filaments Collective motor dynamics seems to be needed to induce filament drift sequential update parallel update L = 50, k = 1000 L = 50, k = 1000 sequentiell update parallel update 0,8 0,8 distance [10nm] distance [10nm] 0,6 0,6 0,4 0,4 0,2 0,2 0 0 -0,2 -0,2 0 250 500 0 250 500 time [sec] time [sec] Ines Weber

Tug-of-war model for filaments Results sequential update L = 50, k = 1000 sequentiell update 0,8 distance [10nm] single motor motion 0,6 0,4 • many uncoordinated motors 0,2 • large filament deformation, no global motion 0 -0,2 • motor energy is absorbed in filament buckling 0 250 500 time [sec] L = 50, k = 1000 parallel update parallel update collective motor motion 0,8 distance [10nm] 0,6 • competitive motors 0,4 • filament stays straight and shows drift 0,2 0 • similar to fast + and - motion in -0,2 tug-of-war model 0 250 500 time [sec] Ines Weber

Summary Uncoordinated motor motion • semi-flexible filament + uncoordinated motors ➡ sequential update • velocity depends on the stiffness and on the force ratio • quasi Gaussian fluctuations, H ≈ 0 . 5 • diffusion coefficient indicates at least two fluctuation regimes ➡ Motors are not able to induce global drift and persistent movement. Coordinated motor motion • semi-flexible filament + coordinated motors ➡ parallel update • Tug-of-war model • stiff filaments and large force ratio needed ➡ Coordinated motor motion is needed for persistent movement. Ines Weber

Thanks to ... •Annette Kraegeloh and Katharina Narr Leibniz Institute for New Materials ‣ Fluorescent Microscopy •Alexandra Kiemer and Birgit Wahl Universität des Saarlandes ‣ Fluorescent Microscopy •Joachim Weickert Universität des Saarlandes ‣ Image Enhancement and Deconvolution Ines Weber

Recommend

More recommend