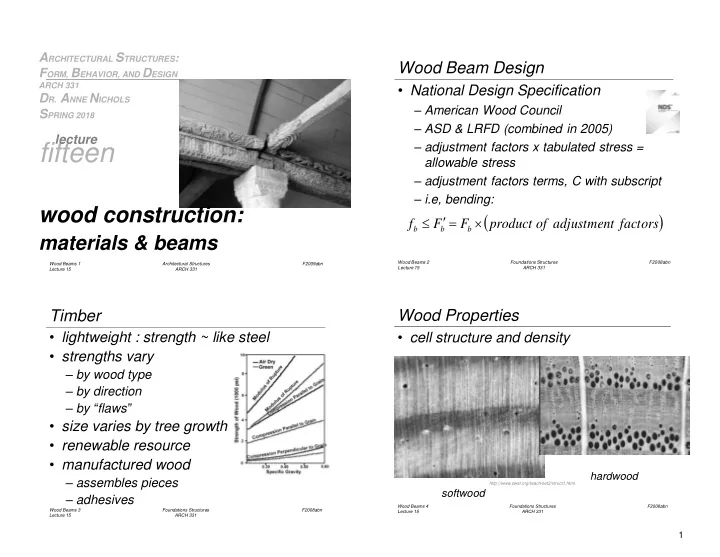

A RCHITECTURAL S TRUCTURES : Wood Beam Design F ORM, B EHAVIOR, AND D ESIGN ARCH 331 • National Design Specification D R. A NNE N ICHOLS – American Wood Council S PRING 2018 – ASD & LRFD (combined in 2005) lecture – adjustment factors x tabulated stress = fifteen allowable stress – adjustment factors terms, C with subscript – i.e, bending: wood construction: f F F product of adjustment factors b b b materials & beams Wood Beams 2 Foundations Structures F2008abn Wood Beams 1 Architectural Structures F2009abn Lecture 15 ARCH 331 Lecture 15 ARCH 331 Wood Properties Timber • lightweight : strength ~ like steel • cell structure and density • strengths vary – by wood type – by direction – by “ flaws ” • size varies by tree growth • renewable resource • manufactured wood hardwood – assembles pieces http://www.swst.org/teach/set2/struct1.html softwood – adhesives Wood Beams 4 Foundations Structures F2008abn Wood Beams 3 Foundations Structures F2008abn Lecture 15 ARCH 331 Lecture 15 ARCH 331 1

Wood Properties Wood Properties • moisture • load duration – exchanges with air easily – short duration – excessive drying causes warping and • higher loads shrinkage – normal duration – strength varies some • > 10 years • temperature • creep – steam – additional – volatile products deformation with no additional load – combustion http://www.swst.org/teach/set2/struct1.html Wood Beams 5 Foundations Structures F2008abn Wood Beams 6 Foundations Structures F2008abn Lecture 15 ARCH 331 Lecture 15 ARCH 331 Structural Lumber Adjustment Factors • dimension – 2 x ’ s (nominal) • terms – C D = load duration factor • beams, posts, timber, planks – C M = wet service factor • grading • 1.0 dry 19% MC sawn – select structural • 1.0 dry 16% MC glu-lam – no. 1, 2, & 3 – C F = size factor • tabular values • visually graded sawn by species lumber and round timber • > 12” depth • glu-lam Fig. 9.23 (pg 477) 1 C F ( 12 / d ) 9 1 . 0 • plywood Wood Beams 8 Foundations Structures F2008abn Wood Beams 7 Foundations Structures F2008abn Lecture 15 ARCH 331 Lecture 15 ARCH 331 2

Adjustment Factors Adjustment Factors • terms • terms – C fu = flat use factor – C r = repetitive member factor • not decking – C H = shear stress factor – C i = incising factor • splitting • increase depth for pressure treatment – C V = volume factor – C t = temperature factor • same as C F for glue laminated timber • lose strength at high temperatures – C L = beam stability factor • beams without full lateral support – C c = curvature factor for laminated arches Wood Beams 9 Foundations Structures F2008abn Wood Beams 10 Foundations Structures F2008abn Lecture 15 ARCH 331 Lecture 15 ARCH 331 Allowable Stresses Load Combinations • design values • design loads, take the bigger of – F b : bending stress – (dead loads)/0.9 – F t : tensile stress strong – (dead loads + any possible combination of – F v : horizontal shear stress weak live loads)/C D – F c : compression stress • deflection limits (perpendicular to grain) – no load factors – F c : compression stress (parallel to – for stiffer members: grain) strong • T max from LL + 0.5(DL) – E: modulus of elasticity – F p : bearing stress (parallel to grain) Wood Beams 11 Foundations Structures F2008abn Wood Beams 12 Foundations Structures F2008abn Lecture 15 ARCH 331 Lecture 15 ARCH 331 3

Beam Design Criteria Beam Design Criteria • superpositioning • strength design – use of beam charts – bending stresses predominate – elastic range only! – shear stresses occur – “ add ” moment diagrams • serviceability – “ add ” deflection CURVES – limit deflection and cracking + + (not maximums) – control noise & vibration – no excessive settlement of foundations = = – durability – appearance – component damage – ponding Wood Beams 13 Foundations Structures F2008abn Wood Beams 14 Foundations Structures F2008abn Lecture 15 ARCH 331 Lecture 15 ARCH 331 Beam Deformations Deflection Limits • curvature relates to • based on service condition, severity 1 M R – bending moment R Use LL only DL+LL EI – modulus of elasticity Roof beams: – moment of inertia y c L Industrial L/180 L/120 ½ ½ Commercial M ( x ) curvature plaster ceiling L/240 L/180 EI no plaster L/360 L/240 M ( x ) slope dx Floor beams: EI Ordinary Usage L/360 L/240 M ( x ) deflection dx Roof or floor (damageable elements) L/480 EI Wood Beams 15 Foundations Structures F2008abn Wood Beams 16 Foundations Structures F2008abn Lecture 15 ARCH 331 Lecture 15 ARCH 331 4

Lateral Buckling Timber Beam • lateral buckling caused by Bracing compressive forces at top coupled with insufficient rigidity • can occur at low stress levels • stiffen, brace or bigger I y Wood Beams 17 Foundations Structures F2008abn Wood Beams 18 Foundations Structures F2008abn Lecture 15 ARCH 331 Lecture 15 ARCH 331 Design Procedure Beam Design 1. Know F all for the material or 4*. Include self weight for M max F U for LRFD – and repeat 3 & 4 if necessary 5. Consider lateral stability 2. Draw V & M, finding M max h Unbraced roof trusses f b 3. Calculate S req ’ d F were blown down in b b 1999 at this project in 2 bh Moscow, Idaho. S 4. Determine section size Photo: Ken Carper 6 Wood Beams 18 Foundations Structures F2008abn Wood Beams 19 Foundations Structures F2008abn Lecture 15 ARCH 331 Lecture 15 ARCH 331 5

Beam Design Beam Design 6. Evaluate shear stresses - horizontal 7. Provide adequate bearing P f • area at supports F f F v v p p A 3 V V f • rectangles and W ’ s v max 2 A A web VQ f v • general max Ib Wood Beams 20 Foundations Structures F2008abn Wood Beams 21 Foundations Structures F2008abn Lecture 15 ARCH 331 Lecture 15 ARCH 331 Beam Design Beam Design 8. Evaluate torsion 9. Evaluate deflections f F v v • circular cross section T f v J • rectangular T f v y ( x ) 2 c 1 ab max actual allowable Wood Beams 22 Foundations Structures F2008abn Wood Beams 23 Foundations Structures F2008abn Lecture 15 ARCH 331 Lecture 15 ARCH 331 6

Decking Joists & Rafters • across beams or joists • allowable load tables (w) • floors: 16 in. span common • allowable length tables for common – ¾ in. tongue-in-groove plywood live & dead loads • lateral bracing needed – 5/8 in. particle board over ½ in. plywood – hardwood surfacing • common spacings • roofs: 24 in. span common – ½ in. plywood Wood Beams 24 Foundations Structures F2008abn Wood Beams 25 Foundations Structures F2008abn Lecture 15 ARCH 331 Lecture 15 ARCH 331 Engineered Wood Engineered Wood • plywood • glued-laminated timber – veneers at different – glulam orientations – short pieces glued – glued together together – split resistant – straight or curved – higher and uniform strength – grain direction parallel – limited shrinkage and swelling – higher strength – used for sheathing, decking, shear walls, – more expensive than sawn timber diaphragms – large members (up to 100 feet!) – flexible forms Wood Beams 26 Foundations Structures F2008abn Wood Beams 27 Foundations Structures F2008abn Lecture 15 ARCH 331 Lecture 15 ARCH 331 7

Timber Elements Engineered Wood • I sections • stressed-skin elements – beams – modular built-up “ plates ” • other products – typically used for floors or roofs – pressed veneer strip panels (Parallam) – laminated veneer lumber (LVL) • wood fibers – Hardieboard: cement & wood Wood Beams 28 Architectural Structures F2008abn Wood Beams 29 Foundations Structures F2008abn Lecture 15 ARCH 331 Lecture 15 ARCH 331 Timber Elements Timber Elements • built-up box sections • trusses – built-up beams – long spans – usually site-fabricated – versatile – bigger spans – common in roofs Wood Beams 30 Foundations Structures F2008abn Wood Beams 31 Foundations Structures F2008abn Lecture 15 ARCH 331 Lecture 15 ARCH 331 8

Timber Elements Timber Elements • folded plates and arch panels • arches and lamellas – usually of plywood – arches commonly laminated timber – long spans – usually only for roofs Wood Beams 32 Structural Systems I Su2008abn Wood Beams 33 Structural Systems I Su2008abn Lecture 15 COSC 321 Lecture 15 COSC 321 Approximate Depths Wood Beams 34 Structural Systems I Su2008abn Lecture 15 COSC 321 9

Recommend

More recommend