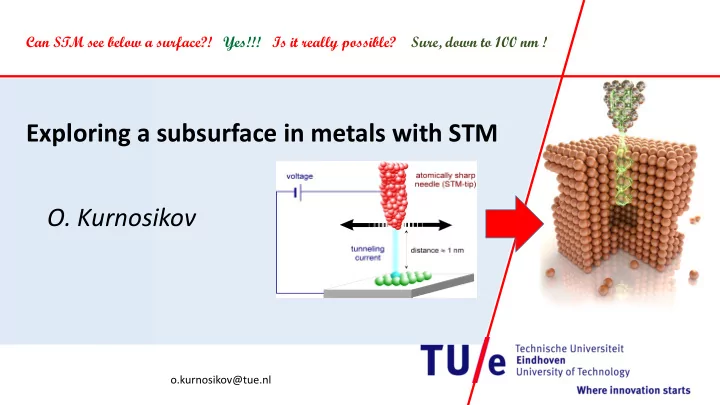

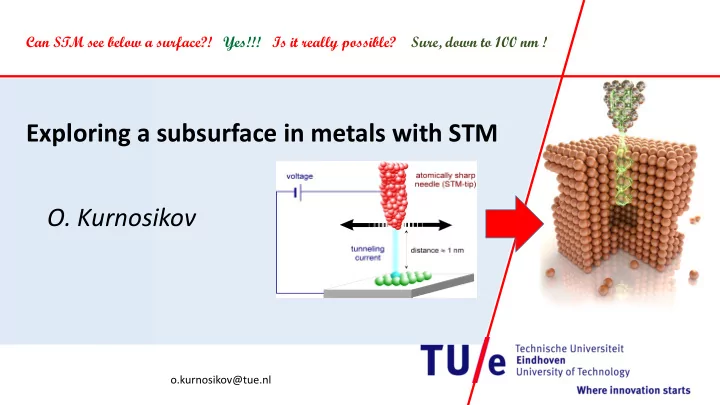

Can STM see below a surface?! Yes!!! Is it really possible? Sure, down to 100 nm ! Exploring a subsurface in metals with STM O. Kurnosikov o.kurnosikov@tue.nl

Introduction: Scanning Tunneling Microscopy/Spectroscopy In selected points For each (x,y) Spectroscopy (STS) Topography Conductance mapping Cu(111) 7.8Å atomic resolution Resolution Lateral : atomic, ~0.1nm Vertical : subatomic, ~0.001nm Two ways of get the subsurface sensibility: 1. Subatomic variation of the relief 2. Perturbation of surface electron reflects the Density of States density

Relief variation Mismatch of crystalline lattices of substrate and impurity atoms or embedded nanocluster . Co nanoclusters embedded below Cu(001) surface, 75 x 75 nm 2 . Relaxation of crystalline lattice and interaction of embedded atoms Deformation 20 pm Ar bubble below Cu(001) surface, 30 x 15 nm 2 .

Buried nanocavities and clusters: TU/e results Ar nanocavities in Cu(001), the same area, different bias What we have and Studied system what we see [110] [110] 60 × 60 nm 2 500mV 600mV Ar nanocavities in Cu(110), the same area, different bias Shape: different spots – different facets 4 Ar-, Ne- or He- filled nanocavities 3 have much stronger scattering effect 2 1 and therefore they can be detected much dipper than single impurities atoms. The nanocavities are visualized in STM measurements as spots of different contrast above their locations. The contrast D E 110 oscillates with bias. From the 1 oscillation period the depth can be 400mV 500mV 60 × 60 nm 2 deduced. Different facets of D E ss nanocavities induce different if ΔΕ =0,25 mV 3 2 oscillation phase and period. From then d = 12 nm this the shape and size of the 4 nanocavity can be determined.

Ultimate depth detection: nanocavities in Cu(110) – 80 nm Nanocavities vs Ar-filled nanocavities in Cu(110) Applications Nanoclusters Depth 4.5 nm For ITER Degradation of W or Mo walls by implantation and growth of H 2 and 12.5 nm He-filled nanocavities: the growth of nanicavities can be visualizeed Metallic clusters provide less For micro- nanolithography 22.4 nm effective scattering. Ar, Ne, He implantation defects in conducting Nevertheless we can see Co layers (Al, Cu, Au, Ag, …) during plasma processing and Fe nanoclusters up to 25 or magnetron sputtering deposition 32.5 nm nm deep. Co nanoclusters in Cu(001) For clean material technology 1.15 1.10 10 nm of Cu dI/dV @ 900mV 1.05 39.0 nm Study near-surface defects and interfaces directly or by 1.00 1.1 0.95 decoration them with He or H nanocavities 0.90 dI/dV / dI 0 /dV (a.u.) 0.85 1.0 0.80 0.0 0.5 1.0 1.5 0.9 52.9 nm 1.00 -0.5 0.0 0.5 1.0 1.5 2.0 For solar cells and nanophotonics Bias voltage (V) 40 x 40 nm 0.95 Ge nanoclusters and nanovoids in fused Fe nanoclusters in Cu(001) 1.10 0.0 0.5 1.0 1.5 silica 62.8 nm 6 nm of Cu dI/dV @ 400mV 1.05 1.00 0.95 0.0 0.5 1.0 1.5 1.00 80.0 nm 0.95 30 x 30 nm 0.0 0.5 1.0 1.5 20 x 20 nm 2

Our experiments Application for ITER: Shape of nanocavity in W Possible Wulf constructions Tungsten with impurities Pure tungsten Estimated size ~15 nm 20 x 20 nm G 1,4 ~10 nm 0.22mV 1,3 1,2 (dI/dV)/dIo/dV) 1,1 1,0 0,9 R. Kositski, D. Mordehai / Acta Materialia 90 0,8 (2015) 370 – 379 R. Jacobs, D. Morgan, and J. Booske 0,7 ArXiv 1712.05308.pdf 0,6 -0,2 0,0 0,2 0,4 0,6 0,8 1,0 1,2 10/31/2019 6 Bias voltage, V 6

Recommend

More recommend