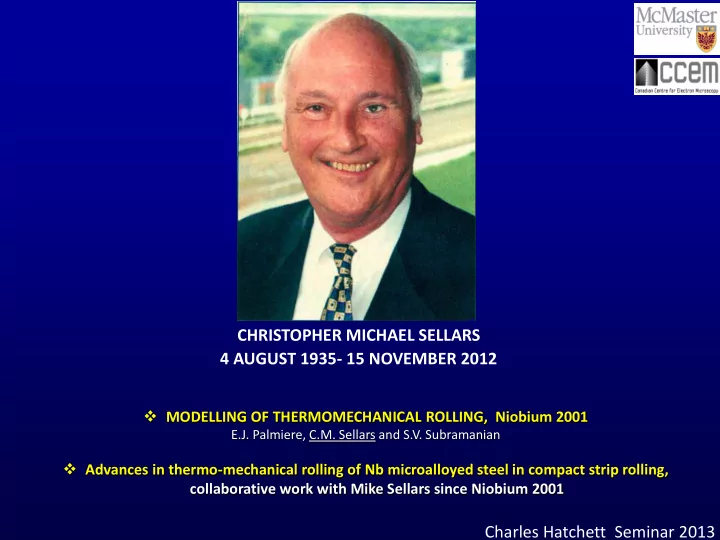

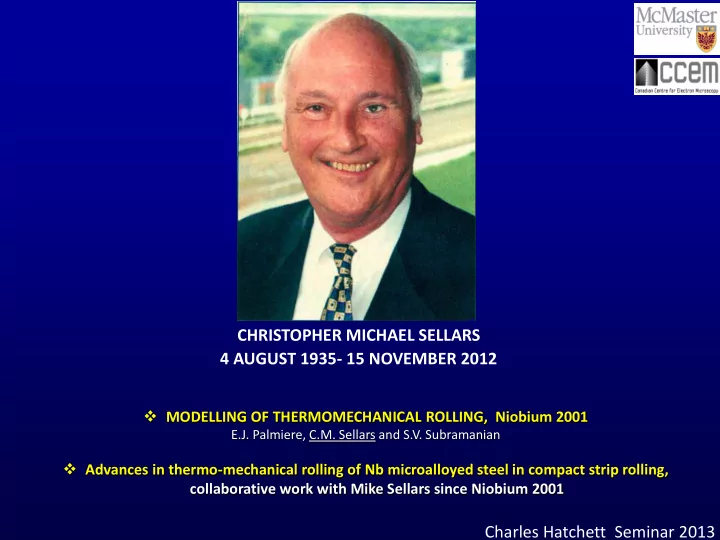

CHRISTOPHER MICHAEL SELLARS 4 AUGUST 1935- 15 NOVEMBER 2012 MODELLING OF THERMOMECHANICAL ROLLING, Niobium 2001 E.J. Palmiere, C.M. Sellars and S.V. Subramanian Advances in thermo-mechanical rolling of Nb microalloyed steel in compact strip rolling, collaborative work with Mike Sellars since Niobium 2001 Charles Hatchett Seminar 2013

Outline Dedication to Mike Sellars 1. What is the market driver for near net shape processing? 2. What are the mill options available currently to process thin slab and how they differ from conventional hot strip mills? 3. What are the metallurgical perspective/ modeling capabilities we have to-date to produce higher grade line pipe in thicker gages, using knowledge-base on TMCP of niobium microalloying gained in plate rolling? 4. What are the engineering challenges to meet the metallurgical requirements? 5. What are the target parameters in terms of morphological and crystallographic structure and how we have achieved X-70 using the currently available three mill designs? 6. What is a viable strategy to meet the market demand to produce X-80 and higher grades in thicker gages? Design of next generation mill should integrate mill design with metallurgical requirements of microalloying grades 7. What next after 10 years of TMCP? 8. Acknowledgements Charles Hatchett Seminar 2013

What is the MARKET DRIVER? Thin slab direct rolling ( TSDR) offers Energy saving of 1080 kJ/kg of steel and CO 2 saving of 0.3 kg/kg of steel. Source: Environmental protection agency (EPA), US Govt, Sep 2012 What are the existing MILL OPTIONS available for strip rolling and the niche each offers from metallurgical perspective? Conventional Danieli-1 (Danieli-2) CSP HSM Mitsubishi Rougher 5-7, Reversing 1, Non 2, Non 0 Reversing Reversing RM Temp, C 1180-1040 1120 1120-980 N.A. RM Exit GS, µm 7-12 150 15-20 1000 FME Temp, C 1000 1050 950-900 1040 FME GS, µm 40-70 150-230 25-40 <1000 FME Thk, mm 30-50 45-50 30 70 Possible Redn below 66% 40% 60% N.A. T NR for 12.5 mm Charles Hatchett Seminar 2013

Conventional Vs CSP Target Parameters at finish mill entry 1180C-1050C Temp<920C GS:25-40 µm Conventional Hot Strip Mill Holding furnace Rolling Stands FME=1040C GS=600-1000µm caster CSP type Strip Mill In CSP mill ,coarse as-cast grain (1000µm) enters Finishing Mill as there is no roughing stand. This has to be refined and then pancaked. Rolling in partial recrystallization regime is difficult to avoid Charles Hatchett Seminar 2013

Danieli -First and second Generation design D-I t Refine the austenite grain size to 180µm at the end of R1. Continue to refine in F1 and dummy F2, difficult to avoid rolling in partial recrystallization regime Target Parameters at finish mill entry Temp<920C GS:25-40 µm D-II Refine the austenite grain size to 30µm at the end of R2. FM entry temperature can be independently controlled to enter below TNR to avoid rolling in partial recrystallization regime

Thermo-mechanical controlled processing - to control microstructure evolution Metallurgical perspective based on plate rolling of X-80 and above Module-1 Grain refining Grain coarsening ------------- Module-2 Strain accumulation -------------- Module-3 Transformation Hardening Grain size effect Solid solution strengthening Precipitation strengthening Thermo-mechanical rolling of plate of higher grade niobium micro-alloyed line pipe steel

Novel insight from plate rolling studies Concept-1: Grain refinement austenite before pancaking is the key to suppress competition from brittle fracture as measured by %age shear in DWTT- Basis for OHTP process (Charles Hatchett award paper- 2011) Without OHTP With OHTP Effect of grain size on the ductile-brittle transition temperature in bainite-martensite structures. (a) Effect of austenite grain size on a 700 MPa proof stress bainitic steel. (T. Gladman and F.B. Pickering ) Charles Hatchett Seminar 2013

Concept-1 continued: Control of crystallographic HAGB is the key to control of brittle fracture. Miao Chengliang, C. Shang and You Yang, C. Shang and S.V. Subramanian, 2011 S.V. Subramanian, 2010 Charles Hatchett Seminar 2013

Concept-2: Refinement of austenite grain upstream to can be used to compensate for less pass reduction available for strain accumulation in finish rolling in thin slab processing using the well established concept of Sv factor in Kozazu’s diagram for plate rolling. Austenite grain refinement compensates for reduced total deformation inherent in thin slab technology to obtain the same Sv factor (surface to volume ratio of austenite grains) as in conventional processing of plates to give the same number density of nucleation sites for ferrite grain refinement. This offers a novel strategy to produce thicker gage in thin slab processing Charles Hatchett Seminar 2013

Novel use of Kozazu’s Diagram on Sv factor for compact strip rolling Concept 2 contd. Increases Sv factor without high deformation below T NR. Advantage in rolling thicker sections and in thin slab rolling.

Challenge-1 : How to control austenite grain size before pancaking 1375 µm As-Cast (before R1) 180 µm After R1

Challenge-2: Metallurgical control of microstructure is coupled to heat transfer control that is controlled by mill design Dr.-Ing. Thomas Heller,

Controlled accelerated Finish rolling carried Grain refinement Laminar cooling Solidification cooling and coiling temp. out Tnr) -pan caked and solute Nb are of austenite by Microstructure to form acicular ferrite used to prevent austenite grain Length Scales > 1000 static transformed at low grain coarsening thickness 6 to 12µm recrystallization - to 1500 µm of austenite and temperature to meet target depending on entry after two stand enter finish rolling acicular ferrite- bainitic austenite grain size and roughing – below Tnr ( 920C) ferrite microstructure with per centage total to avoid rolling in Aim: 15 to 25 µm high density and reduction in finishing partial recrystalli- dispersion of high angle zation regime – mill allowable by gage boundaries to yield X-80 typically 960-920C) thickness) properties.

Mitsubishi- Hitachi Danieli-2 nd Generation (2 Roughing Stands ) Prev. practice without IMC Our Recommendation with IMC Coarsening Kinetics Refinement of austenite grain size by rolling reduction of 38% in R1 at 1070 o C & 34% in R2 at 1048 o C followed by coarsening till F1.

Mitsubishi-Hitachi-Danieli-2 nd Generation(for arctic grade), 2012 F2 F3 F4 R2 R1 F1 Mitsubishi DSPC CSP Charpy Impact, J 310 (12.2mm, 0C) 444 (12.86mm,-15C) 215 (3/4 th , 11.1mm,0C) 524, 45 o YS 530 512 UTS 606 613 593, 45 o %El 32.7 41 34 Charles Hatchett Seminar 2013

TMCP- What Next? Control of T NR F. Borrato, J.J Jonas, S.V.Subramanian and C.M.Sellars Growth of NbC on well dispersed TiN can obviate the need for strain induced precipitation and serve to raise Tnr which will allow rolling hot, thereby reducing the mill load. The key is good Charles Hatchett Seminar 2013 density and dispersion of TiN precipitates.

Future direction • X70 in 12mm has been demonstrated in all three available near net shape mill designs, CSP, Danieli and Mitsubishi-Hitachi. • The feasibility of obtaining ultra fine grains of 1-2 um has been demonstrated which gives an optimum combination of strength and formability suitable for automotive grades. • The modeling capability has allowed us to predict target parameters for producing higher grades of line pipe steel but the mill has to be designed around the metallurgical requirement of Time-Temp-Deformation schedule of pass reduction. • Good dispersion of TiN can be used to advantage to promote epitaxial growth of Nb(C,N) so as to avoid strain induced precipitation of NbC, thereby raising the temperature of no recrystallization for the same chemistry. This will allow finish rolling at elevated temperature, which will reduce the rolling load in processing higher niobium grades. Charles Hatchett Seminar 2013

Acknowledgements 1. Late Dr. Mike Sellars 2. Dr Lutz-Meyer 3. Dr R. Kasper 4. Dr G.R.Purdy 5. Dr. John Jonas 6. Dr Francisco Borato 7. Dr.G.Zhu 8. Dr H. Zurob 9. Dr P. Hodgson 10. Dr C. Shang 11. Dr Kevin Banks 12. Dr.T. Zhou 13. Dr M. Chengliang 14. Kashif Rehman

Recommend

More recommend