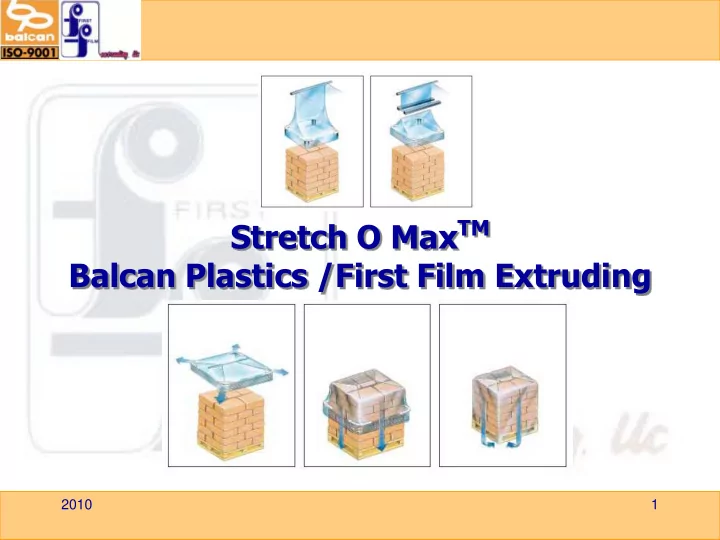

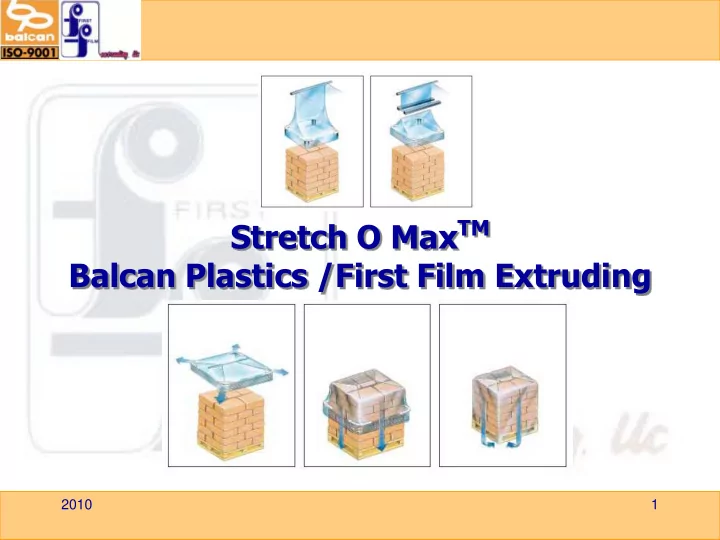

Stretch O Max TM Balcan Plastics /First Film Extruding 2010 1

Stretch O Max™ can be better than stretch wrap 1) Less wrapping material: A single stretch hood bag replaces a combination of stretch wrap + strapping + pallet cover. 2) Full automation: Save labor and process supervision. 3) Better branding: Print your logo and company name on all sides rather than on top and 2 sides. 4) Save on warehousing costs with outdoor storage: Stretch hood is more weather resistant. 5) New Stretch O Max TM film of Balcan/First Film has excellent load retention, puncture and stretch-ability. 2010 2

Stretch O Max™ Process Step 1: Gathering of the right length film over the 4 horns Step 2: Film sealing for a hood or film cutting for a sleeve Step 3: Stretching up to 90% to fit over the load Step 4: Film pulled down by the horns and released Step 5: Last part of the film is released under the load Overall process: 20 – 60 seconds depending on machine 2010 3

Stretch O Max TM applications Pallets of Shipping Sacks Peat Moss, Aggregates, Chemicals, Fuel Pellets. Pallets of Boxes Laminate flooring, Tissue, Battery Casing, Roofing shingles. Pallets of Brick and Pavers. Appliances. Stoves, Refrigerators, Air conditioning units. Foam insulation panels. 2010 4

Applications Low Stretch, high puncture film: • Foam insulation panels : 15-25% stretch • Roofing shingles: 20% stretch • Air conditioning units: 30% stretch 2010 5

Applications Medium Stretch, high load retention film: • Brick & Block: 30-60% Stretch • Shipping sacks: 30-60% Stretch 2010 6

Applications Super stretch: • Appliances : Stretch 50-100% • Pallets of cases : Stretch 60-90% 2010 7

Stretch O Max ™ film for all markets TOUGHNESS High High toughness Medium High Stretch LOW Stretch Stretch Regular STRETCH % 25% 50% 75% 8

Balcan/First Film Product Line 1) Low stretch < 25% Stretch up to 25% , good load retention, good toughness options: slip, color , printing, sizes up to 140” 2) Medium Stretch 25% < x < 55% Stretch up to 55%, high load retention, regular toughness options: slip, color, printing, sizes up to 140” 3) High Stretch > 55% Stretch up to 90%, high puncture & tear strength options: slip, color, printing, sizes up to 98 ” 4) High Toughness for robust or cold applications Stretch up to 40%, high puncture & tear strength options: slip, color , printing, sizes up to 140” 2010 9

Information to Know Film Variables Tubing size, film type, slip, color, printing, Economics Questions to ask Pallet/load size, load retention requirements, film sample, machine age and type Key Film Properties to talk about Ability to stretch, load retention, film toughness 2010 10

The secret of Stretch O Max Film 1. The right bag size 2. Elasticity (not just stretch-ability) 3. Ability for the film to release from the arms with no tears 4. No tears due to double folds 5. Quality control, film consistency 6. Puncture strength application specific 7. Load retention application specific 8. Clarity application specific 2010 11

Recommend

More recommend