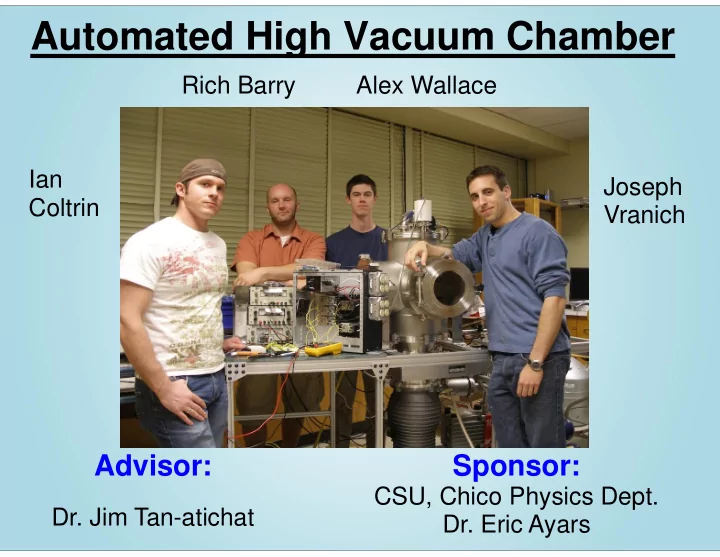

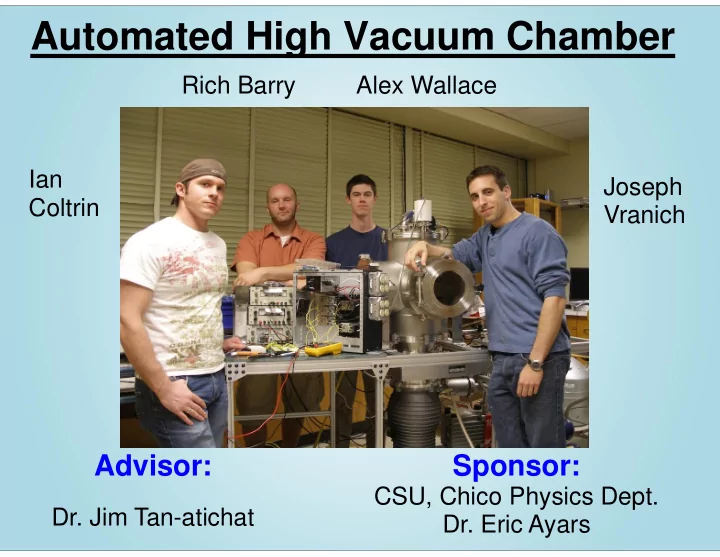

Automated High Vacuum Chamber Rich Barry Alex Wallace Ian Joseph Coltrin Vranich Advisor: Sponsor: CSU, Chico Physics Dept. Dr. Jim Tan-atichat Dr. Eric Ayars

Background and Need Need Statement: The CSU, Chico Physics Department needs a vacuum chamber to perform a greater variety of experiments for students and faculty alike. Goal Statement: Design, build, and test a vacuum chamber that achieves high vacuum made with parts already donated.

Project Requirements The Design Solution Must: • Be capable of producing and maintaining high vacuum • Be capable of automated operation

The Design Solution Should: • Be modifiable/modular • Have hardware support for future lab work • Be usable by students • Have a control system programmed in a familiar environment It Would Be Nice if the Design Solution: • Was mobile • Included a closed loop cooling system

Metrics/Targets Requirement Engineering Metric Method/Device Target Condition Specification 10 -6 -10 -7 High Vacuum Pressure Torr High Vacuum Maintained for Pressure Gage Torr at least 3 hrs.

Design Changes • Mechanical o Custom Chamber Support o Custom 'double-port' o Foreline and venting components � Diameter reduction o Additional donation integration • Mechatronic o Control system sensors o Control interface o Pump-down procedure

Design Solution interface screenshot

Double Port • Needed flexibility in future chamber arrangements o Each face of the main chamber is valuable • Choices for the connection of the foreline and the IG o Individual 6-way faces for IG and foreline � Wasteful o Combine foreline and IG connection into one face � Potential for bad gauge reading? � Non-issue • Custom component allows for multiple positions

Foreline Design • Metal bellows tubing used to prevent collapse under vacuum • Additional donated inline valve altered the foreline • Redesigned the venting system to use a solenoid

Chamber Body and Sealing All chamber components cleaned with Acetone and Isopropyl Alcohol. All seals given a small coat of vacuum grease Once under vacuum, all gaskets compress and seal tightly

Possible Double Port Actual Configuration Attachments

Control Software • State machine in LabVIEW • Monitors system state for safe operation • Fully auto and "manualmatic" modes • Interfaces to the real world using USB DAQ • Fine tuning of the pump down procedure accomplished during test runs • Allowed "Software in the Loop" & "Hardware in the Loop" development

VI Generations "Software in the Loop" Vacuum Control 1.0 Basic control state machine Vacuum Control 2.0 Correct pumping sequence User interfacing "Hardware in the Loop" Vacuum Control 3.0 & 3.1 Sensor interfacing I/O Restructuring Vacuum Control 4.0 Statistical smoothing of sensory data Error handling

Instrumentation and Interfacing • Main Chamber Pressure o Combination ion gauge reads from atmosphere to high vacuum � RS-485 � Interfaced via NI RS-485 to USB cable • Foreline Pressure o Thermocouple gauge � Interfaced using BoB A/D � Measures ATM to rough vacuum • Coolant Temp o Thermistors installed in coolant lines � Wheatstone bridge � Measured by BoB A/D

RS-485 Interface, Thermistor Circuits

Power 115VAC / 58 Amps • Total potential power draw for the system o No power source previously in the lab could support this • Installed additional power source o 2-pole 115VAC 30A • Distribute the power to various loads in the system • Control the power to the loads, control the loads

PDU Wiring Schematic

Pneumatics • Powered by 100 psi on board air compressor • Dual Manifolds with Regulator o Split Pressure Ranges • Pneumatic tubing with one touch fittings allows for ease of use and greater modularity

Cooling Open loop cooling with temperature monitoring using 2 wire resistance thermistors. 1) 2) 3) 4)

Fabrication/Assembly

Mark 1 • So excited to get parts, built a test stack to check the rough pump • Built the pump stack to test seals and connections • Performed pump maintenance on both pumps to improve performance o flushed oil reservoir o cleaned filters o oil change

Mark II • Received more parts • Built chamber body using 6-way • Installed ion gauge • High vacuum ready • Pumped down to high vacuum and began fine tuning the system software

PDU Fabrication • Installed SSR's for power control • Manufactured copper bus terminals for power distro • Prototyped a driver board for SSR/solenoid control and BoB interfacing • Mounted wall sockets on the front of the case, simple plug and play operation • Appropriate circuit protection installed o Circuit breakers for each major load

PDU Fabrication Process

Mark III - The Final Mark

Testing

Reaching the End Goal

Test Data Checks: Autonomous valve operation Final Pressure Time to High Vacuum Correct user prompting

Checks in the Boxes Requirements: Should Modifiable/Modular Support equipment for future experiments Usable by students Programmed in a familiar language Would be Nice Mobile Closed loop cooling

Final Budget

Final Budget Summary: Mechanical Mechatronic Component Price Component Price Overall Chamber $866 High vacuum gauge $972 Foreline (Tubing, Feedthrough) $2234 PC $300 Valves/Pneumatics $132 Breakout Device $99 Misc (Cold Cap) $450 Power Supplies $22 Total $3682 Misc (wire, terminals, etc.) $250 Total $1634 Donated Component Price Total Purchased: $5316.00 Chamber Pieces $14096 Foreline Connections $283.50 Total Cost Overall: $23724.50 Valves $4029 Total $18408.50

Labor Fall 2009 Design Mechanical Electrical Software Total Hours 416 441 260 1153 Cost $14,547.50 $15,421.80 $9,092.20 $40,320.40 Spring 2009 Assembly and Test Mechanical Electrical Control System Total Hours 650 450 700 1352 $22,730.47 $15,736.43 $24,479.00 $62,945.9 Cost

Why this system is so cool • Automated vacuum systems are normally expensive • Design provides a great learning environment • Built on a lean budget • Achieved high vacuum (900 nTorr) within 45 minutes on the first attempt!

Suggested Future Changes • Addition of a thermal evaporation system and other experiments o Makes the chamber useful • Closed loop cooling system o Simple and inexpensive designs available o Creates a more conservative and cost effective system • Oil Vapor Filter for the Roughing Pump o Conserves oil o Keeps the system clean inside and out

Acknowledgements Craig Myers, Gino Giordano, Doug Reid from Duniway, Paul Young from Adixen, Jordan Lynn from NI, Dr. Ayars, Robert Kieth, Nick from FMS, Lisa Washburn, Dr. Gaffney, Dr. Ayars, Collier's Hardware staff, Mike Kellog From LAM who donated parts, Dale Word, etc... Thanks Everybody!

Questions?

Recommend

More recommend