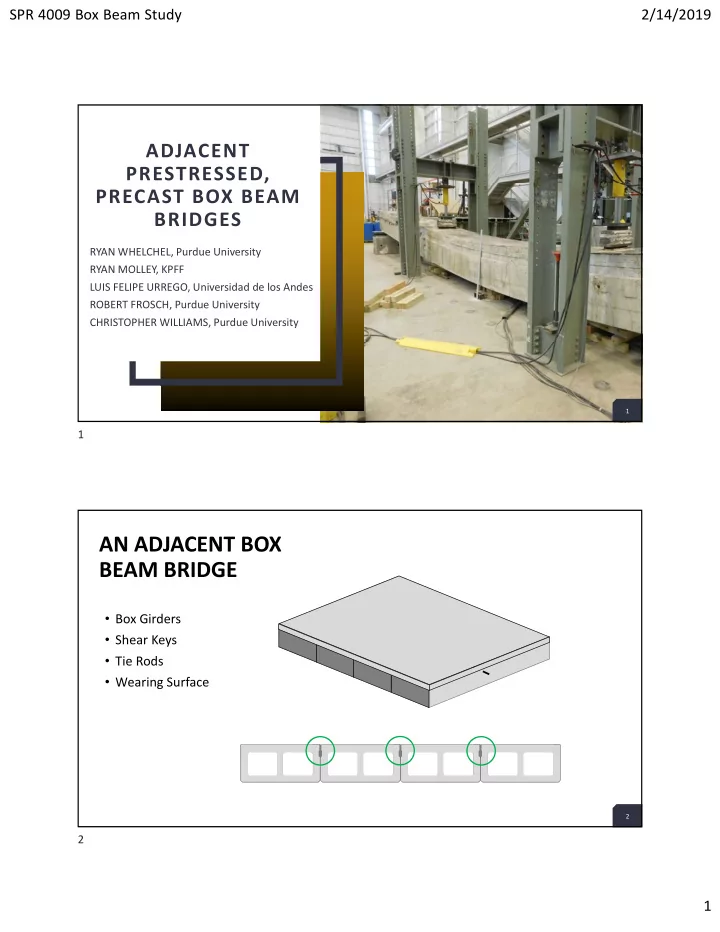

SPR 4009 Box Beam Study 2/14/2019 ADJACENT PRESTRESSED, PRECAST BOX BEAM BRIDGES RYAN WHELCHEL, Purdue University RYAN MOLLEY, KPFF LUIS FELIPE URREGO, Universidad de los Andes ROBERT FROSCH, Purdue University CHRISTOPHER WILLIAMS, Purdue University 1 1 AN ADJACENT BOX BEAM BRIDGE • Box Girders • Shear Keys • Tie Rods • Wearing Surface 2 2 2 1

SPR 4009 Box Beam Study 2/14/2019 PROJECT MOTIVATION • History of poor durability and performance • Economical and simple to build • Over 43,000 in US and 4,000 in Indiana 3 3 RESEARCH PLAN • Acquire decommissioned bridge girders • Research and acquire NDT equipment • Conduct non‐destructive evaluation • Perform structural tests • Load test an existing bridge to determine load distribution of a non‐composite deck on a bridge without shear keys 4 4 2

SPR 4009 Box Beam Study 2/14/2019 SPECIMEN ACQUISITION • Determine those bridges that will be replaced • Inspect bridges to determine specimen quality • Contact County, Engineer, or Contractor to coordinate girder salvage 5 5 COMMON DETERIORATION • Longitudinal Cracking • Exposed or Broken Strand 6 6 3

SPR 4009 Box Beam Study 2/14/2019 BOX BEAM SPECIMENS Wells Co. Bridge 79 7 7 7 BOX BEAM SPECIMENS Newton Co. Bridge K5 8 8 8 4

SPR 4009 Box Beam Study 2/14/2019 BOX BEAM SPECIMENS Elkhart Co. Bridge 102 9 9 9 NONDESTRUCTIVE TESTING 10 5

SPR 4009 Box Beam Study 2/14/2019 NON‐DESTRUCTIVE EVALUATION (NDE) Ground Penetrating Radar Connectionless Electrical Half‐cell potential Pulse Response Analysis measurement (GPR) (CEPRA) 11 11 PRELIMINARY NDE RESULTS Specimen 409‐1‐ES Span: 50’ Depth: 29” Width: 36” 12 12 6

SPR 4009 Box Beam Study 2/14/2019 PRELIMINARY NDE RESULTS 36.0 Transverse Location (in.) Connectionless Electrical Pulse 30.9 Response Analysis 25.7 20.6 15.4 10.3 5.1 0 0 5 10 15 20 25 30 35 40 45 50 Longitudinal Location (ft) Low Moderate High 13 13 PRELIMINARY NDE RESULTS 36.0 Transverse Location (in.) 30.9 Half‐cell potential measurement 25.7 20.6 15.4 10.3 5.1 0 0 5 10 15 20 25 30 35 40 45 50 Longitudinal Location (ft) Low Moderate High 14 14 7

SPR 4009 Box Beam Study 2/14/2019 STRUCTURAL TESTING 15 BEAM TEST Load Points Roller Bearing Reaction Block (TYP) (TYP) String Potentiometers (two at midspan) 16 16 16 8

SPR 4009 Box Beam Study 2/14/2019 BEAM TEST ~ 12 in. Specimen 409‐1‐ES • Three exposed strands at L/8 from support Specimen 409‐2‐UD • No damage 17 17 17 BEAM TEST 60 42 kip - Undamaged 52 kip - Test Capacity 50 Applied Force (kip) 47 kip - Theory 40 30 34 kip - Damaged Capacity 20 10 0 0 5 10 15 20 25 Midspan Deflection (in.) 18 18 18 9

SPR 4009 Box Beam Study 2/14/2019 BEAM TEST 60 42 kip - Undamaged 50 kip - Test 50 Capacity Applied Force (kip) 47 kip - Theory 40 30 20 10 0 0 5 10 15 20 25 Midspan Deflection (in.) 19 19 19 BEAM TEST 60 52 kip - Test 50 kip - Test 50 Applied Force (kip) 47 kip - Theory 40 30 20 10 0 0 5 10 15 20 25 Midspan Deflection (in.) 20 20 20 10

SPR 4009 Box Beam Study 2/14/2019 FIELD TESTING 21 TIPPECANOE COUNTY BRIDGE 115 • Built: 1957 • Rehabilitated: 1993 • Span: 40 ft • Beam Depth: 21 in. • Beam Width: 45 in. • 7 Beams 22 22 11

SPR 4009 Box Beam Study 2/14/2019 INSTRUMENTATION INTRODUCTION 10’ 10’ 10’ 10’ 23 23 LOADING Dump Truck • Weight: ~ 58,000 lb • 30% to front axle • 70% to tandem axle • Wheelbase: 16’ – 4” 24 24 12

SPR 4009 Box Beam Study 2/14/2019 � � T E S T 3 T E S T 4 T E S T 1 T E S T 2 25 25 25 FIELD TESTING Bridge Deck Modifications • Milling • Shear Key Cutting • Surface Preparation • Bridge Deck Cast 26 26 26 13

SPR 4009 Box Beam Study 2/14/2019 East West 10' 10' 10' 10' 1 2 3 4 5 6 7 LT1 ‐ Original Condition 0 ‐0.02 Midspan Deflection (in.) ‐0.04 LT2 ‐ Asphalt Removed ‐0.06 ‐0.08 ‐0.1 LT3 ‐ Shear Keys Disabled ‐0.12 ‐0.14 LT4 ‐ Concrete Deck Placed ‐0.16 ‐0.18 ‐0.2 1 2 3 4 5 6 7 Beam Number 27 27 27 East West 10' 10' 10' 10' 1 2 3 4 5 6 7 0 ‐0.02 Concrete Deck Placed Midspan Deflection (in.) ‐0.04 35% reduction in ‐0.06 ‐0.08 deflection Original Condition ‐0.1 ‐0.12 ‐0.14 ‐0.16 ‐0.18 ‐0.2 1 2 3 4 5 6 7 Beam Number 28 28 28 14

SPR 4009 Box Beam Study 2/14/2019 LOAD DISTRIBUTION • The proportion of load carried by a given beam was calculated as follows ∆ ������� � 𝐸𝐺 � � ∑ ∆ ������� � 29 29 East West 1 2 3 4 5 6 7 10' 10' 10' 10' Beam Number 1 2 3 4 5 6 7 0% 5% Load Distribution 10% 15% 20% 25% 30% LT01 LT04 30 30 15

SPR 4009 Box Beam Study 2/14/2019 East West 1 3 5 6 7 2 4 10' 10' 10' 10' Beam Number 1 2 3 4 5 6 7 0% 5% Load Distribution 10% 15% 20% 25% 30% LT01 LT04 31 31 LOAD DISTRIBUTION SUMMARY Experimental Design Distribution Factors Distribution Factors Load Test Interior Exterior AASHTO Standard Specification 2002 LT01 22% 23% Load Fraction (truck) LT04 22% 25% 32% AASHTO LRFD 2017 Interior Exterior 21% 24% 32 32 16

SPR 4009 Box Beam Study 2/14/2019 FIELD TEST CONCLUSIONS • Concrete deck restored load distribution to a code level • Durability and stiffness were added to the system • Composite action between the deck and the beams was achieved 33 33 IMPLICATIONS TO BEST PRACTICE • Recommend all new construction use Concrete Deck concrete decks Sealant • Potential new design of adjacent box beam bridges without shear keys Standard Box Beam Shape 34 34 17

SPR 4009 Box Beam Study 2/14/2019 PROJECT BENEFITS • Improved inspection capability for bridge inspectors • Increase in bridge load rating accuracy • Development of next generation box beams 35 35 ACKNOWLEDGMENTS 36 18

SPR 4009 Box Beam Study 2/14/2019 THANK YOU 37 19

Recommend

More recommend