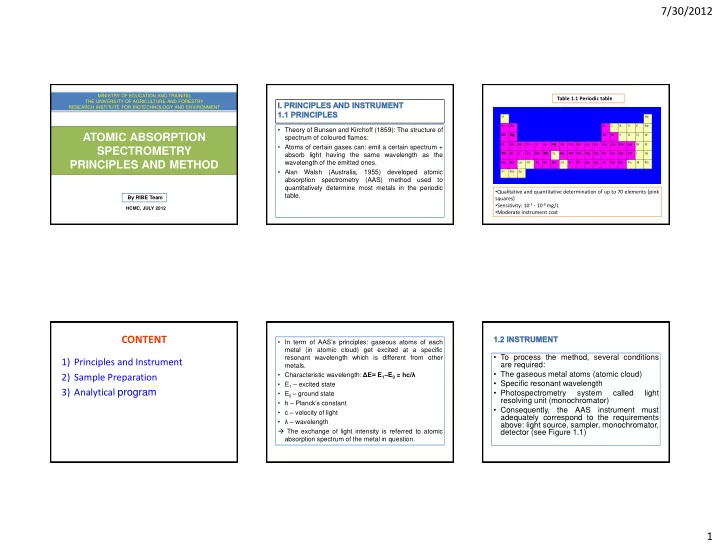

7/30/2012 MINISTRY OF EDUCATION AND TRAINING Table 1.1 Periodic table THE UNIVERSITY OF AGRICULTURE AND FORESTRY RESEARCH INSTITUTE FOR BIOTECHNOLOGY AND ENVIRONMENT • Theory of Bunsen and Kirchoff (1859): The structure of ATOMIC ABSORPTION spectrum of coloured flames: • Atoms of certain gases can: emit a certain spectrum + SPECTROMETRY absorb light having the same wavelength as the PRINCIPLES AND METHOD wavelength of the emitted ones. • Alan Walsh (Australia, 1955) developed atomic absorption spectrometry (AAS) method used to quantitatively determine most metals in the periodic • Qualitative and quantitative determination of up to 70 elements (pink table. By RIBE Team squares) • Sensitivity: 10 -3 - 10 -6 mg/L HCMC, JULY 2012 • Moderate instrument cost CONTENT • In term of AAS’s principles: gaseous atoms of each metal (in atomic cloud) get excited at a specific • To process the method, several conditions resonant wavelength which is different from other 1) Principles and Instrument are required: metals. • The gaseous metal atoms (atomic cloud) • Characteristic wavelength: ΔE= E 1 – E 0 = hc/λ 2) Sample Preparation • Specific resonant wavelength • E 1 – excited state 3) Analytical program • Photospectrometry • E 0 – ground state system called light resolving unit (monochromator) • h – Planck’s constant • Consequently, the AAS instrument must • c – velocity of light adequately correspond to the requirements • λ – wavelength above: light source, sampler, monochromator, The exchange of light intensity is referred to atomic detector (see Figure 1.1) absorption spectrum of the metal in question. 1

7/30/2012 A = log (1/T) = log(P O /P) = e*b*c • 2.2 SUMMARY OF METHOD A : absorbance • 2.2.1 A representative 0.3 g (wet weight) sample T = P/P O : transmittance is heated with repeated additions of nitric acid (HNO 3 ) and hydrogen peroxide (H 2 O 2 ). P O : initial radiant power of a beam Figure 1.1 Generic AA spectrometer • 2.2.2 Hydrochloric acid (HCl) is added to the P : radiant power of the beam after being absorbed digestate. This digestate will be filtered. Then the e : the molar absorbtivity (L/mol.cm) filter paper and residues are rinsed with reagent b : the path length of the sample (path length of the cuvette in which the sample is contained) water. After all, the digestate is diluted to a final c : the concentration of the compound in solution (mol/L) volume of 100 mL. Figure 1.2 SpectrAA 220 Varian 7.2.1 Add 5 ml 7.1 Cut, mill, 7.2 Add 10 mL Brief: key considerations in quantitative conc. HNO3 and HNO3: and Start and mix sample reflux for 30 mins. to homogeneity. reflux for 10 (repeat until brown determination of heavy metal by AAS Weigh 0.3 gram minutes fume is gone). Heat 2 hours. instrument: 2.1 SCOPE AND APPLICATION Cool. • Flame temperature • 2.1 This method is the digestion procedure of 7.3 Add 2 mL H2O • Beam height vegetable samples used to analyze heavy + 3 mL H2O2 7.5 - 7.6 7.4 Add 10 mL 7.3.2 Heat at 30%; continue to • Aspiration rate and aerosol quality 95 ± 5 0 C without add 1 ml aliquots metal by flame atomic absorption Centrifuge, Filter, conc. HCl. Heat mark the volume for 15 mins. boiling for 2 of H2O2 until hours bubbling subsides. • Interferences spectrometry (FLAA). • 2.2 This method is not an ideal digestion • Correlation between concentration and 7.6 Analyze by 7.7 Calculations FAAS technique for most samples. Because, there is absorbance relied on Beer’s Law strong acid mixture that dissolves almost all elements being available in the environment. Figure 2.1 Acid digestion of vegetables 2

7/30/2012 2.3 QUALITY CONTROL AND QUALITY • Soaking them in acid bath overnight ASSURANCE PROCEDURES FOR TRACE • Rinsing with DI water and drying in oven. C m x V METALS IN FRUITS Conc. Mg in sample = --------------- (mg/Kg) • Note: Wearing gloves, laboratory coat and m • 2.3.1 For each batch of samples processed, a eye-protect glasses. method blank should be carried throughout the o C m : Mg conc. according to standard curve. entire sample preparation and analytical o V: the final volume of process. These blanks will be useful in extract (ml). o m: weight of sample determining if samples are contaminated. (g). • 2.3.2 Spiked duplicate samples should be processed on a routine basis. Spiked duplicate samples will be used to determine precision and bias. Figure 2.3 Clean up Figure 2.2 Typically analytical report 2.3.3 Restricting contamination • 3.1 SAMPLE PREPARATION • 2.3.3.1 Controlling water quality • 3.1.1 SAMPLE REPLICATION • There are 3 distinct species of fruit. Each fruit is • Using distilled water and Deionised water sampled 3 times (3 replications) • Checking filter every month • Prepare 2 blanks controlling this batch of • Replace a new one when contamination is digestion. determined 2.3.3.2 Cleaning up • Removing residues Figure 2.2 (cont.) Typically analytical report • Washing these tubes by distilled water Figure 3.1 Chéri, guava, and litchi 3

7/30/2012 • 3.1.2 RECOVERY • To test the recovery of the procedure, o Strictly comply the method manuals replicate a certain fruit 3 times. Each o Implement blanks, replications, and digestion tube containing recovery sample recoveries is spiked 1 mg/L magnesium. o Avoid cross contamination • NOTE: The replications and recoveries of o In case OVER signal is presented, dilute this batch would follow the same this sample procedure, at the same time. o Be careful in diluting concentrated samples Figure 3.4 Analytical equipments ACTUAL PROCEDURE REFERRENCES 3.2 Standard Preparation From an aqueous stock standard of Mg 1. Phạm Luan. 1987 . Basic of theory about Atomic 1000 mg/L, prepare 04 concentrations Absorption Spectrometer method . Hanoi General suggested by SpectrAA software. University. 2. SpectrAA – 110/220/880, Operation Manual. 1996. 3.3 Controlling analytical instrument Varian Australia. • Standard curve is linear 3. SW-846, Vol. IA, Chap. 3, Sec. 3.2, Method 3050B Figure 3.2 Step 7.1 • RSD < 10% (EPA: United States Environmental Protection Agency): Acid digestion of Sediments, Sludges, and * Note: Soils. 4. http://www.chem.science.unideb.hu/Pharm/FAAS.pdf • Reslope the curve every 50 samples 5. http://sy.zlgc.org/Upload/20070921021809671.pdf • Renew standard solutions every day 6. http://membres.multimania.fr/ciler/archives/Reports/r eport_9-FAAS.pdf Figure 3.3 Step 7.2 to 7.6 4

7/30/2012 THANK YOU ! 5

Recommend

More recommend