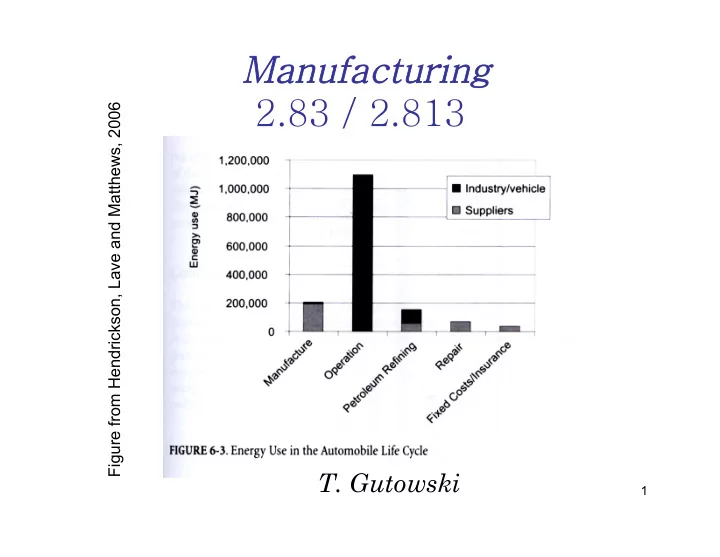

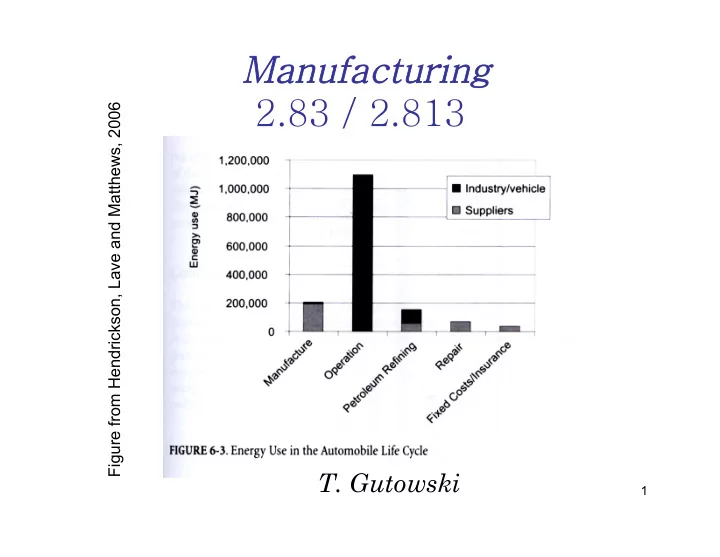

Manufacturing 2.83 / 2.813 Figure from Hendrickson, Lave and Matthews, 2006 T. Gutowski 1

Why is Mfg Energy Important? • 1/3 direct energy • Much of the “indirect - use phase” is in the service of manufacturing • Manufacturing makes the “use phase” devices • For new energy devices (PV, wind, bio…) this will impact energy payback • Manufacturing also contributes to toxics 2

Readings 1) Thiriez, A., “An Environmental Analysis of Injection Molding”, IEEE 2006 Abstract. 2) Williams, E. et al, “The 1.7 Kilogram Microchip”, Enviro. Sci. Technol. 36, 2002, p 5504- 5510. (also see the comment and reply to this article) 3) Williams, E. “Energy Intensity of Computer Manufacturing: Hybrid Assessment Combining Process and Economic Input- Output Methods” Environmental Science and Technology, 2004, 38, 6166- 6174 4) Smil, V., pp 288- 291, Table A.11 3

Energy Used 1. Mfg Sector- Big Picture 2. Mfg Processes- Boundaries, Examples 3. Hybrid Model- Desktop Computer 4

5 Exa = 10 18

Direct Energy Used (EJ), 1992 EJ Percent Mfg(d&i) Total 32.7 38% Industry 30% 22.6 26% Transportation (8%) 17.4 20% Residential 13.4 16% Commercial (5%) 86.1 100% Totals (43%) 6

7

Trends in Mfg Efficiency 8

Energy and Production in the Mfg Sector; 1980 - 1994 DOE, EIA 9

Energy Used 1. Mfg Sector- Big Picture 2. Mfg Processes- Boundaries, Examples 3. Hybrid Model- Desktop Computer 10

Energy Mfg Process Raw Materials Product Equipment Wastes 11

Energy Conversion Mfg Process Equipment 12

Energy Energy Energy Conversion Conversion Conversion Aux. Mfg Mfg Mfg Process Process Process Equipment Equipment Equipment 13

Energy Energy Energy Energy Conversion Conversion Conversion Conversion Aux. Mfg Mfg Mfg Materials Process Process Process Production Equipment Equipment Equipment 14

Energy Energy Energy Energy Conversion Conversion Conversion Conversion Aux. Mfg Mfg Mfg Materials Process Process Process Production Equipment Equipment Equipment Auxiliary Materials Production Energy Conversion 15

Energy Energy Energy Energy Conversion Conversion Conversion Conversion Aux. Mfg Mfg Mfg Materials Process Process Process Production Equipment Equipment Equipment Auxiliary Materials Production Environmental Conditioning Energy Conversion 16

Energy Energy Energy Energy Energy Conversion Conversion Conversion Conversion Conversion Alt. Aux. Mfg Mfg Mfg Materials Materials Process Process Process Production Production Equipment Equipment Equipment Auxiliary Materials Production Environmental Conditioning Energy Conversion 17

Energy Energy Energy Energy Energy Conversion Conversion Conversion Conversion Conversion Materials Aux. Mfg Mfg Mfg Materials Purification Process Process Process Production Production Equipment Equipment Equipment Auxiliary Materials Production Environmental Conditioning Energy Conversion 18

Hybrid Input Output Analysis (transportation, capital equipment, other materials, commercial buildings… 19

Manufacturing Processes Mechanisms: • Plastic Deformation • W/ vol = ∫ τ d γ – Shape change, material removal • Heating • Q = C p Δ T – Heat treat, sinter • Q = C p Δ T + H m • Melting – Welding, molding • Q = C p Δ T + H m + • Vaporization C’ p Δ T + H v – Deposition, etching 20

Specific energy, u S 21 Kalpakjian

Energy requirements at the machine tool Steel~0.7MJ/kg, Alu~0.25MJ/kg Variable Variable (65.8%) (65.8%) Machining (65.8%) Machining (65.8%) Carousel (0.4%) Carousel (0.4%) Spindle (9.9%) Spindle (9.9%) Constant Constant (run time) (run time) Tool Change (3.3%) Tool Change (3.3%) (20.2%) (20.2%) Jog (x/y/z) (6.6%) Jog (x/y/z) (6.6%) Unloaded Motors (2.0%) Unloaded Motors (2.0%) Spindle Key (2.0%) Spindle Key (2.0%) Constant Constant Coolant Pump (2.0%) Coolant Pump (2.0%) (startup) (startup) Servos (1.3%) Servos (1.3%) (13.2%) (13.2%) Computer and Fans (5.9%) Computer and Fans (5.9%) Load Load Production Machining Center Automated Milling Machine Estimate for Steel~0.7 x 3(aux) x 3(utilities)=6MJ/kg removed 22 From Toyota, and Kordonowy 2002.

General electric energy model for mfg processes P = P 0 + k r Power (kW) physics auxiliary equipment & infrastructure Process Rate “r” (kg/hr) Specific Energy (J/kg) P/r = E/m = P 0 /r + k Process Rate “r’ (kg/hr) 23

24

Mostly Vapor Phase Processes Melting & Machining Micro milling machine Spindle drive Size W x D x H = 170 x 170 x 102 mm 3 Spindle power P S = 36 W Rotational speed n = 15,600 min -1 max Spindle drive Microlathe Tool Tool Size W x D x H = 32 x 25 x 30.5 mm 3 Mass m = 98 g Spindle power P S = 1.6 W Rotational speed n = 10,000 min -1 max Tool Tool Sample parts 5 mm 1 mm Source: [EHMA05, MEL07, TANA01] 25

Improvements in machining 26 Kalpakjian

All-electric Vs Hydraulic Injection Molding Machines 9 8 7 All-Electric - 85 tons 6 SEC (MJ/kg) Hydraulic - 85 tons 5 Material: PP 4 3 2 1 0 0 5 10 15 20 Throughput (kg/hr) 27 Source: [Thiriez]

Energy Conversion electricity Energy Conversion gas coal Mfg oil Process Equipment 28

Process Efficiencies See Smil’s Table A.11 Depend on energy source Examples (using best values): gas furnace heating c → t ….. = .94 electric heating c → t → m → e → t (.94)(.425)(.935)(.93)= .347 machine tool c → t → m → e → m (.94)(.425)(.935)(.935)= .349 29

Machining as a product The average power plant in the United States is 35% efficient. 30

50% of the energy from the grid comes from coal • electricity from the US grid comes with – 667 kg of CO 2 /MWh – 2.75 kg of SO 2 /MWh – 1.35 kg of NO x /MWh – 12.3 g Hg/GWh – etc…….. 31 Data from US Energy Information Administration, DOE 2002 & Klee & Graedel

annual SUV equivalents 32

the fine print • Assumptions: Annual emissions resulting from the operation of a typical production machine tool (22 kW spindle, cutting 57% of the time, 2 shifts, auxiliary equipment, electricity from US grid) as measured in annual SUV equivalents (12,000 miles annually, 20.7 mpg) • CO 2 – 61 SUV’s • SO 2 – 248 SUV’s • NOx – 34 SUV’s 33

Electric Grid Characteristics Percentage of Gross Electricity genereated from different fuels and Overall Efficiency of the Electric Grid (including distribution) 34 in 1993 in different European countries [Boustead PVC] and in 2003 in the U.S. [EIA 2004].

Sand Casting 35

Casting Material Flow Input Metal Recycling Product Melting Pouring Cooling Shakeout Trim Finishing Product Metals & Waste Flow Mold Sand Sand Processing Mixing Formation Cooling (AO Treatment) Sand+ Losses Flow Recycling Input Sand 36 A. Jones

Metals used in Casting • Iron accounts for 3/4 of US sand cast metals – Similar distribution in the UK – Share of aluminum expected to increase with lightweighting of automotive parts • Sand used: 5.5t sand:1t casting • Sand lost about 0.5t sand:1t casting in US; 0.25:1 in UK 37 Source: DOE, 1999.

Sand casting; energy profile Measured at the factory • National statistics ( including elect losses) 13 – 17 MJ/kg* • or 6 to 12 MJ/kg* (at the factory) • Melting largest component * of saleable cast metal S. Dalquist 38

Sand casting; energy profile • National statistics ( including elect losses) 13 – 17 MJ/kg* • or 6 to 12 MJ/kg* (at the factory) • Melting largest component * of saleable cast metal Estimate of energy used per kg poured~10 - 12 MJ/kg S. Dalquist 39

Cupola Melting Analysis Metallic Input Materials Gray Iron Products Limestone, Alloys 1.00 tons 1.03 tons Gasses Metallurgical Coke 1,572 kg 87 kg Slag Natural Gas 0.73 tons (Afterburners) 4.05 kg Dust Air and Oxygen 0.4 tons 1,508 kg Boundaries are drawn around the entire facility so that all components are at standard pressure and temperature 40

Induction Melting Analysis Metallic Input Materials Gray Iron Products Alloys 1.00 tons 1.03 tons Slag Electricity 1762 MJ Energy Used at the Factory. Multiply by 3 to get average Dust LHV for fuels used in the US. 0.1 tons Boundaries are drawn around the entire facility so that all components are at standard pressure and temperature 41

Efficiency of Melting: Cupola Melter Energy Required for Melting Iron: Coke Combustion: Heat of Fusion 13.81 kJ/mol Moles of Carbon moles 6,650 Heat Capacity 0.042 kJ/mol*K Exergy/ LHV 394.4 kJ/mol Temperature Raised to 1510.00 Deg C Total Exergy/ LHV MJ 2622.89 Moles of Iron Melted 16751.32 moles Δ H Iron = MJ 1090 η = ( Δ H Iron) / (B coke) 1090 (MJ)/2623 (MJ) → 42% 42

Efficiency of Melting: Electric Induction Melter Energy Required for Melting Iron: Electricity: Heat of Fusion 13.81 kJ/mol Heat Capacity 0.042 kJ/mol*K Temperature Raised to 1482 C Electricity at the Factory MJ 1762 Moles of Iron Melted moles 16,867.35 Δ H Iron = MJ 1079 η = ( Δ H Iron) / (Electricity) 1079 (MJ)/1762 (MJ) → 61% 43

Recommend

More recommend